产品: 2-100mm JGS1 and JGS2 Quartz glass sheets

Featured products

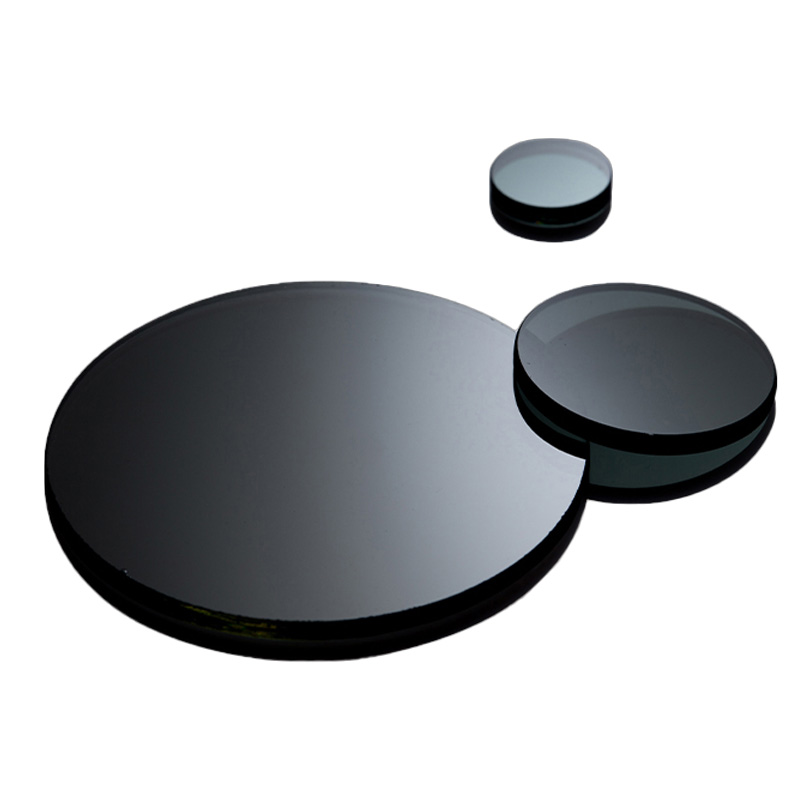

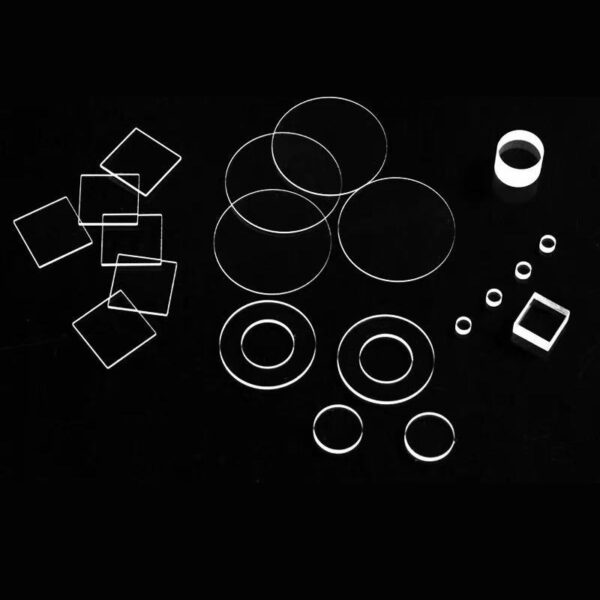

2-100mm JGS1 and JGS2 Quartz glass sheets

Key Specifications – JGS1 and JGS2 Quartz Glass Sheets

| Specification | JGS1 (Synthetic Quartz Glass) | JGS2 (Fused Quartz Glass) |

|---|---|---|

| Material | Synthetic fused silica | Natural fused quartz |

| Thickness Range | 2mm to 100mm | 2mm to 100mm |

| Optical Transmission | Excellent UV, Visible, IR range | Good Visible to IR range |

| Impurity Content | Ultra-low (high purity) | Low (natural impurities) |

| Surface Quality | Scratch-Dig 20/10 – 40/20 (customizable) | |

| Surface Finish | Polished / Ground / Custom | Polished / Ground / Custom |

| Thermal Properties | High thermal shock resistance | High thermal stability |

| Chemical Resistance | Excellent against most acids and bases | Excellent against most chemicals |

| Custom Processing | Irregular shapes, drilling, slots, windows | Irregular shapes, drilling, slots, windows |

| Packaging | Cleanroom packing | Cleanroom packing |

Premium JGS1 and JGS2 Quartz Glass Sheets for Industrial and Scientific Applications

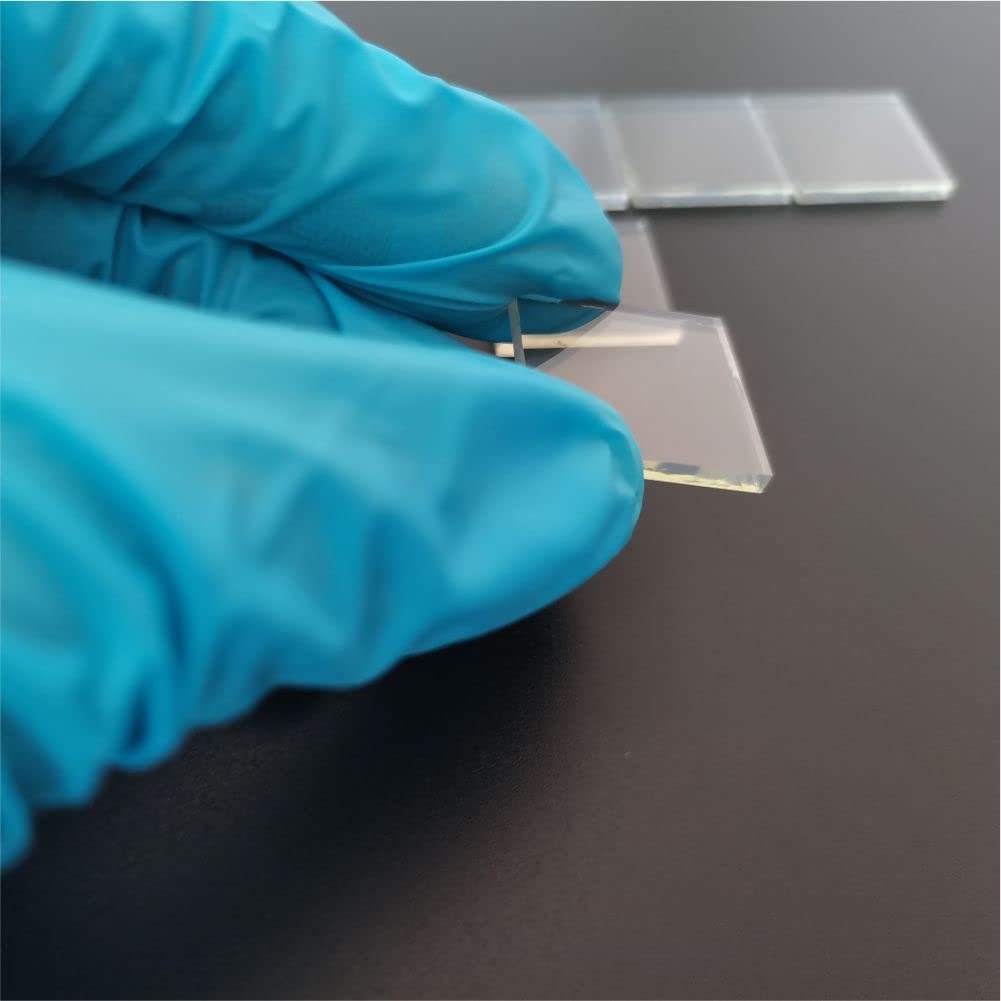

We offer high-purity JGS1 and JGS2 quartz glass sheets ranging from 2mm to 100mm in thickness, designed for demanding applications across industries such as optics, semiconductors, research, and high-temperature manufacturing. As an experienced quartz glass supplier, we specialize in delivering not only standard sheets but also customized irregularly processed quartz glass according to your specifications.

Our JGS quartz products are crafted to meet the highest quality standards, ensuring superior optical performance, exceptional thermal stability, and outstanding chemical resistance.

Key Features of 2–100mm Quartz Glass Sheets

-

- Wide Thickness Range: From ultra-thin 2mm plates to thick 100mm blocks, supporting diverse application needs.

-

- Superior Purity and Optical Performance: JGS1 offers high UV transmission with ultra-low impurities, ideal for sensitive optical and laser applications.

-

- Thermal Shock and High-Temperature Resistance: Both JGS1 and JGS2 withstand extreme thermal cycling and operating temperatures up to 1100°C (JGS2) and 1200°C (JGS1).

-

- Chemical Durability: Outstanding resistance to acids, solvents, and high-purity chemical processes.

-

- Custom Irregular Processing: Specialized fabrication available, including shaped sheets, complex geometries, drilled holes, slots, chamfered edges, and more.

Differences Between JGS1 and JGS2 Quartz Glass

| Property | JGS1 (Synthetic) | JGS2 (Fused Quartz) |

|---|---|---|

| UV Transparency | Higher | Moderate |

| Impurity Level | Lower (ultra-high purity) | Higher (natural origin) |

| Application Focus | Optics, lasers, semiconductor | General industrial, optical windows |

| Cost | Higher | More economical |

JGS1 is preferred when ultra-high purity, UV transparency, and minimal birefringence are critical, while JGS2 offers excellent performance at a more accessible price point for general-purpose applications.

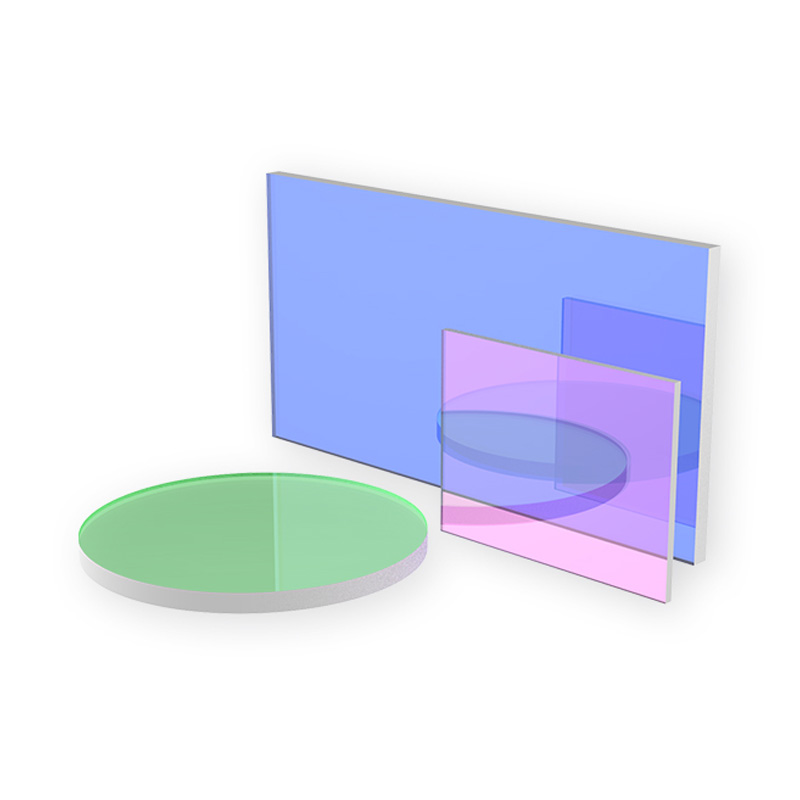

Applications of JGS1 and JGS2 Quartz Glass Sheets

Our 2–100mm quartz glass sheets are widely used in:

-

- Optical Windows and Lenses: UV-grade and IR-grade quartz for precision optics and photonics.

-

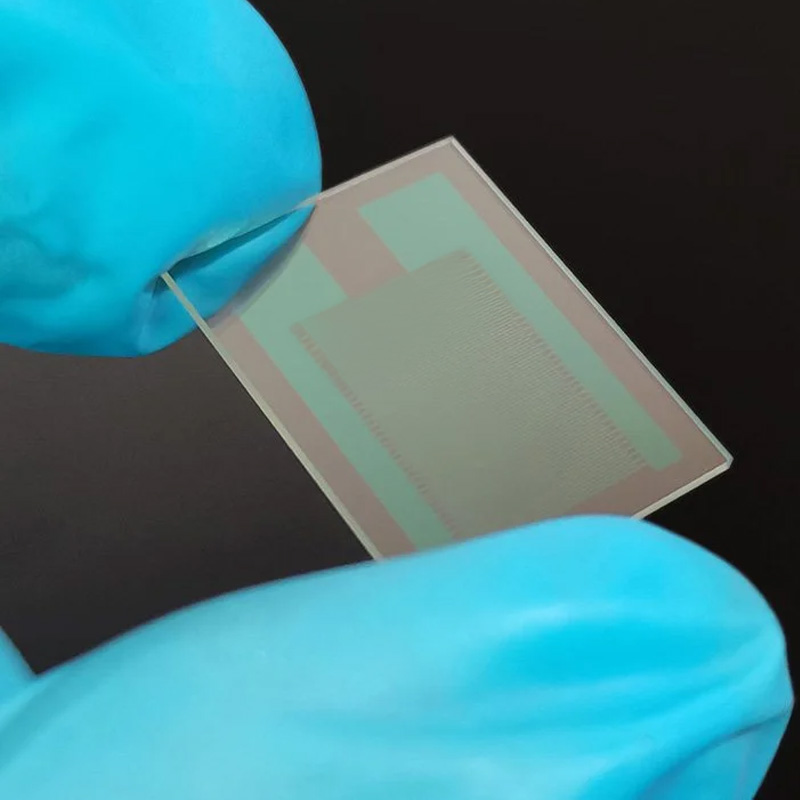

- Semiconductor Manufacturing: Quartz substrates for CVD, diffusion furnaces, and wafer carriers.

-

- Laser Components: Windows, covers, and optical filters in high-power laser systems.

-

- Laboratory and Research Equipment: Reaction vessels, microfluidic substrates, viewports, and spectroscopy platforms.

-

- Medical and Biotechnology Instruments: Quartz optical components for imaging and analysis.

-

- Industrial Processing: Quartz shields, viewing windows for furnaces, and thermal insulation barriers.

Whether for high-energy laser transmission, extreme temperature resistance, or chemical inertness, our quartz glass sheets offer unmatched versatility.

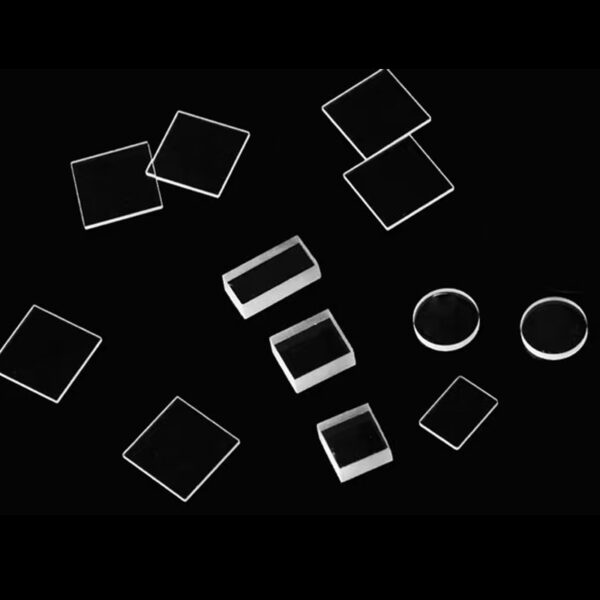

Custom Irregular Processing Options

We understand that many industries require non-standard, precisely fabricated quartz parts. We provide professional irregular shape processing capabilities, including:

-

- Custom Shaped Cuts: Circles, rectangles, polygons, and free-form shapes.

-

- Precision Drilling: Through-holes, blind holes, counterbores with high positional accuracy.

-

- Grooving and Slotting: Channels, slots, and precision milled features for fluidics or mechanical assembly.

-

- Edge Finishing: Chamfering, rounding, and safety seaming for durability and easy handling.

-

- Surface Polishing: Ultra-smooth finishes for optical clarity or ground finishes for adhesion purposes.

-

- Coating Services: AR coatings, hydrophobic coatings, and protective film applications upon request.

Advanced CNC machining, laser cutting, and ultrasonic drilling technologies are used to fabricate even the most complex quartz designs, ensuring dimensional accuracy and surface quality.

Benefits of Choosing Our Customized Quartz Glass

-

- Guaranteed Material Quality: Sourced from verified premium quartz materials, ensuring optical clarity and chemical stability.

-

- Flexible Design Support: We work closely with clients to develop quartz glass solutions tailored to their exact needs.

-

- Rapid Prototyping and Production: Short lead times for prototypes and production volumes, supporting research timelines and industrial scalability.

-

- Global Delivery: Reliable shipping services covering North America, Europe, and the entire Asian market.

Our expertise in handling boro33 glass, wafer glass, and quartz materials ensures we are a one-stop solution for precision scientific and industrial glass needs.

Contact Us for Customized JGS1 and JGS2 Quartz Glass Solutions

If you are looking for reliable, precision-fabricated JGS1 or JGS2 quartz glass sheets, trust our team to deliver customized, high-performance solutions. We offer technical support throughout the selection and fabrication process to ensure that you receive quartz components perfectly suited to your project.

Contact us today for sample requests, quotations, or to discuss your custom irregular quartz glass needs. Experience professional service, fast production, and exceptional quality – from a supplier committed to your success.

Standard Sizes and Custom Options for Quartz Sheets

| Standard Sheet Sizes | Thickness Range |

|---|---|

| 100mm x 100mm | 2mm – 10mm |

| 200mm x 200mm | 2mm – 20mm |

| 300mm x 300mm | 5mm – 25mm |

| 400mm x 400mm | 5mm – 50mm |

| 500mm x 500mm | 5mm – 100mm |

| Custom Geometries | On request |

(Special oversized or irregular dimensions can be fabricated based on your drawings or CAD files.)

Leave Your Message