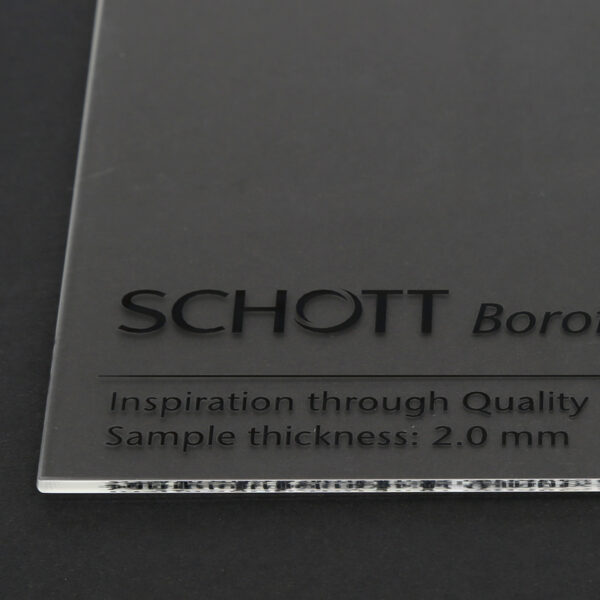

产品: Custom Schott BOROFLOAT® 33 Glass

Featured products

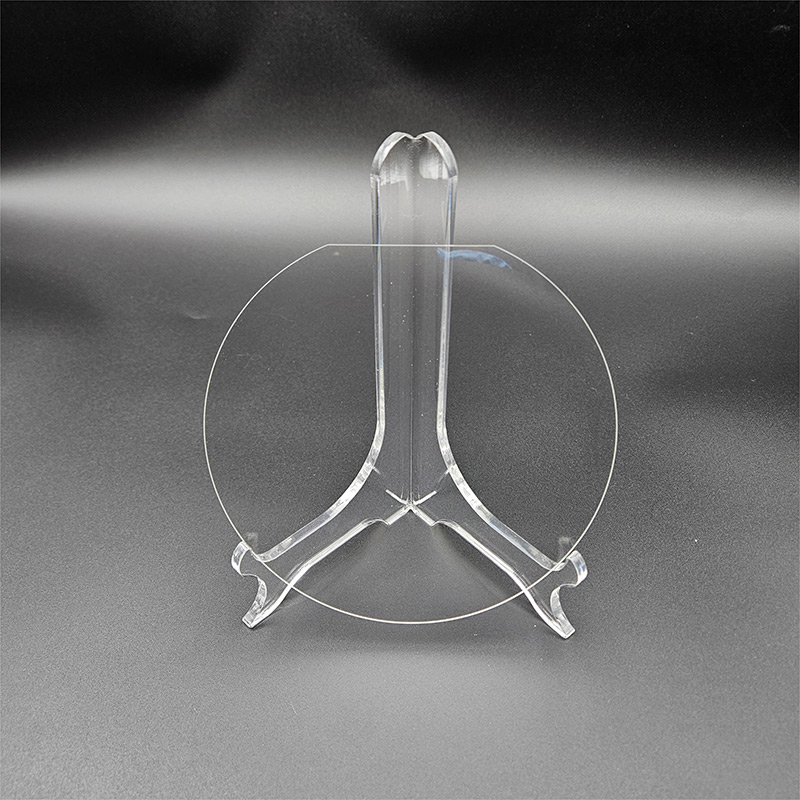

Custom Schott BOROFLOAT® 33 Glass

Technical Specifications of Schott BOROFLOAT® 33

| Property | Value |

|---|---|

| Thermal Expansion (20–300°C) | 3.25 × 10⁻⁶ /K |

| Density | 2.23 g/cm³ |

| Annealing Point | 560°C |

| Softening Point | 820°C |

| Refractive Index (nd) | 1.472 |

| Chemical Resistance | ISO Class 1 (Acid, Hydrolytic), Class 2 (Alkali) |

| Dielectric Constant | 4.6 at 1 MHz |

| Dielectric Strength | 16 kV/mm |

| Available Thicknesses | 0.7 mm to 25.4 mm |

Overview: What is Schott BOROFLOAT® 33 Glass?

Schott BOROFLOAT® 33 is a premium borosilicate glass manufactured in Germany using a micro-float process. Known for its low thermal expansion, excellent optical transmission, and high chemical resistance, it is widely used in technical and scientific applications.

Compared to conventional borosilicate glass, BOROFLOAT® 33 offers superior surface quality, homogeneity, and workability—making it an ideal choice for high-precision components.

Why Choose BOROFLOAT® 33 for High-Performance Applications?

- Thermal Shock Resistance: With a thermal expansion coefficient of 3.25 × 10⁻⁶/K, it withstands extreme temperature shifts.

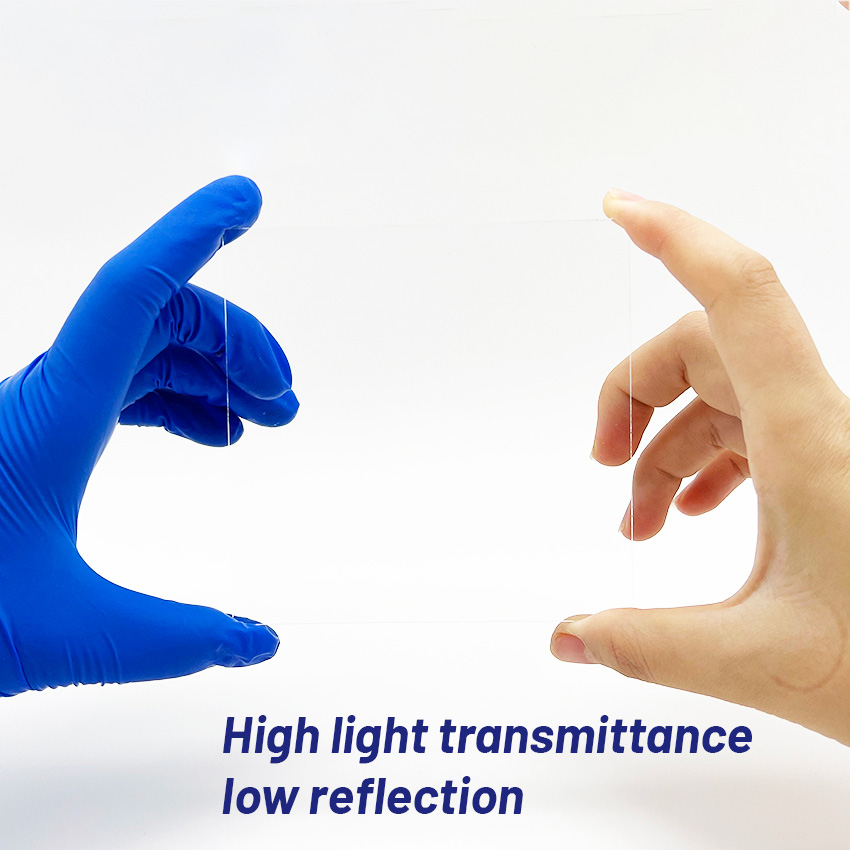

- Optical Quality: Low auto-fluorescence, high transmission in visible and IR spectrum, refractive index ~1.472.

- Mechanical Strength: Knoop Hardness of 480, excellent durability under stress.

- Chemical Durability: Resistant to acids, alkalis, and hydrolytic attack (ISO Class 1).

Your Trusted BOROFLOAT® 33 Supplier and Custom Processor

We are a factory-direct BOROFLOAT® 33 glass supplier offering fully customized solutions for your industrial and scientific needs. Our factory supports:

- Small- and large-batch OEM supply

- Technical consulting for substrate optimization

- International logistics and export documentation

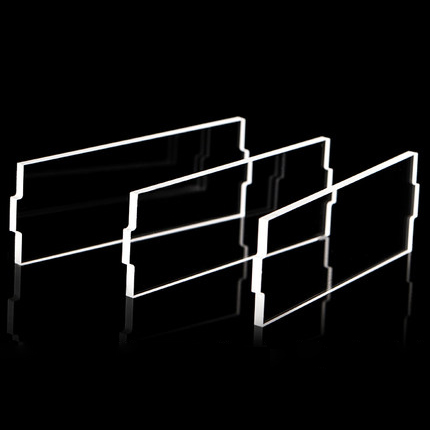

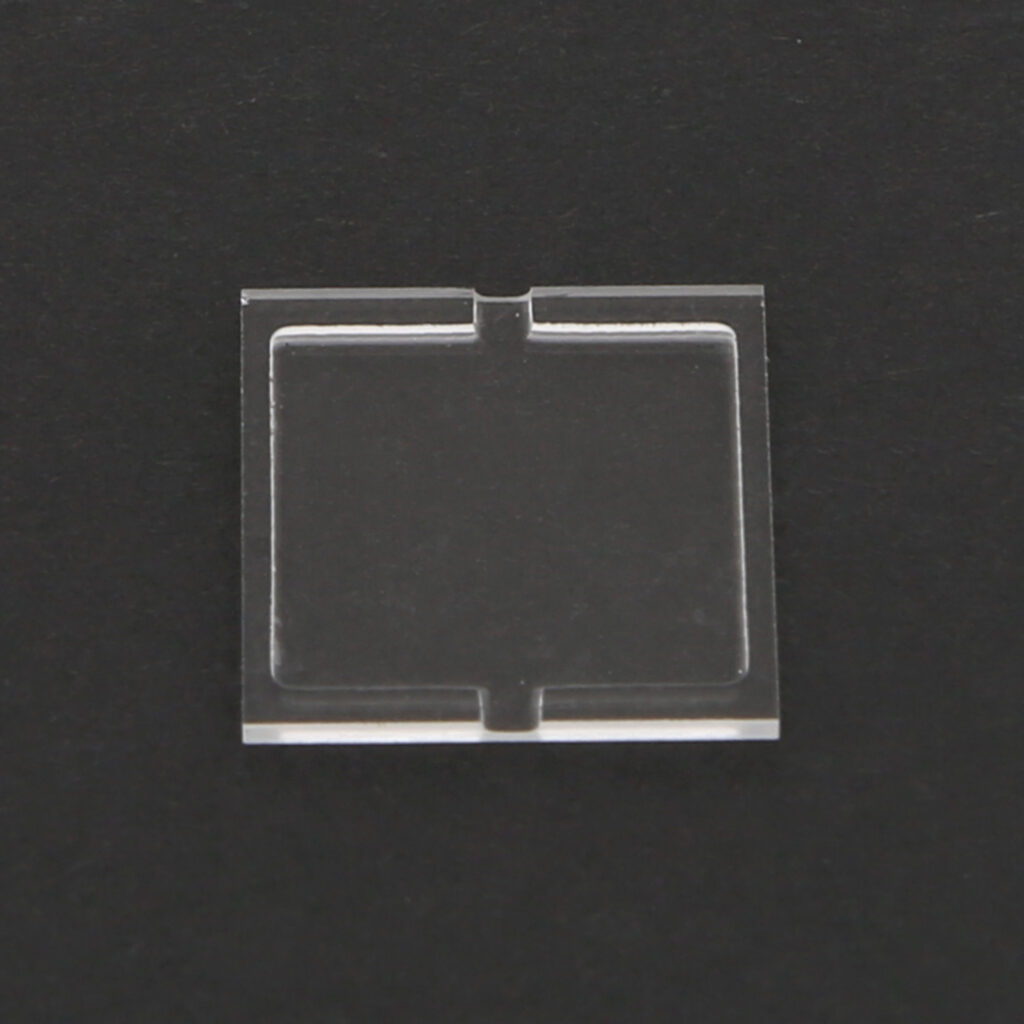

Glass Processing Capabilities for BOROFLOAT® 33

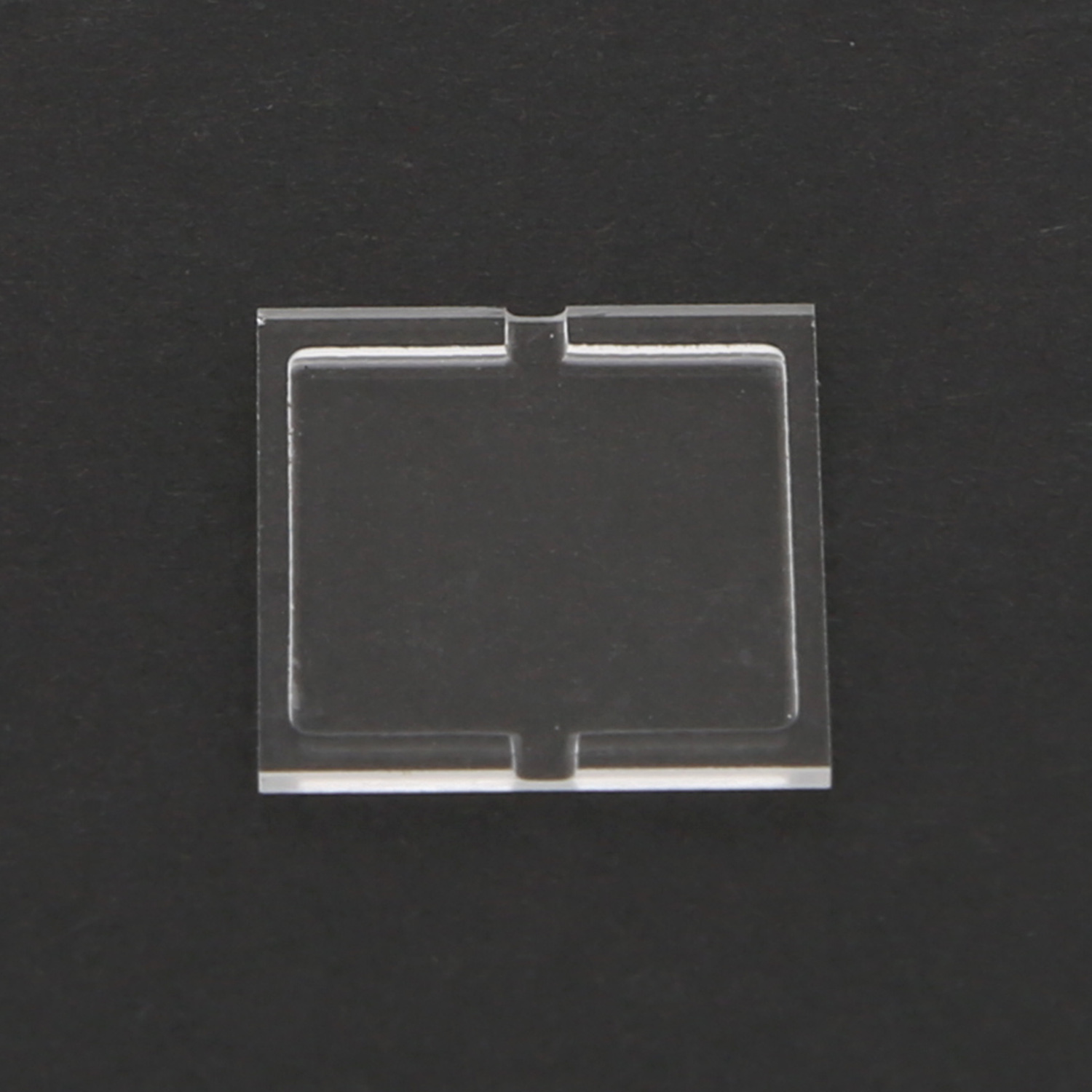

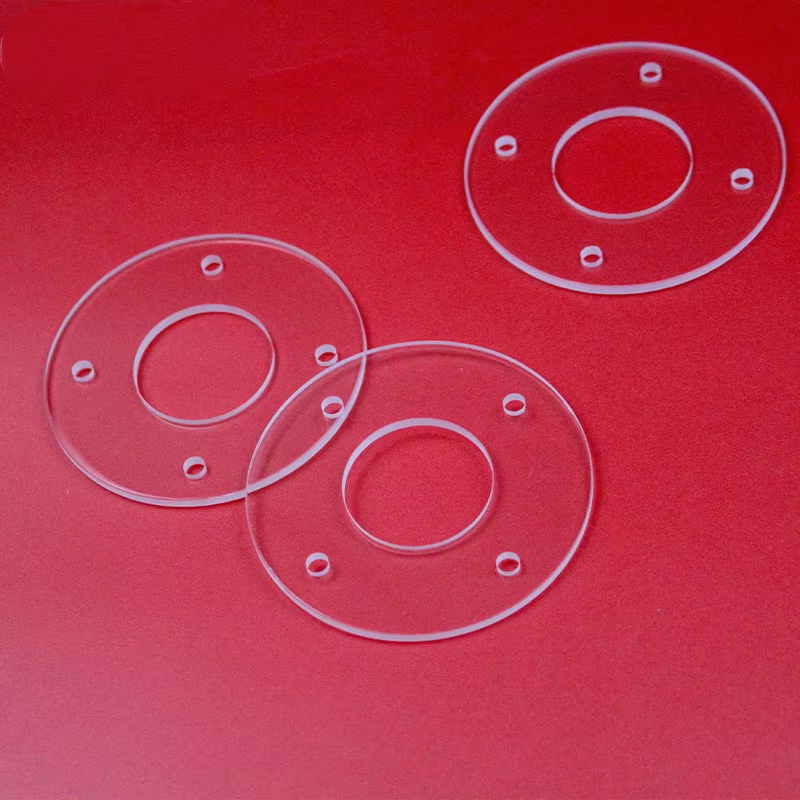

We provide complete in-house fabrication and CNC machining services:

- Precision Cutting: Tolerance up to ±0.01 mm

- CNC Milling & Slotting: Complex geometries for optical and MEMS use

- Edge Polishing: C-edge, D-edge, beveling, and chamfering

- Drilling & Hole Arrays: For microfluidics or instrumentation

- Surface Finishing: Optical polishing, lapping (Ra ≤ 0.01 µm)

- Coating: Anti-reflective, ITO/FTO, dielectric layers

- Thermal Strengthening: Annealing and thermal tempering available

All fabrication is backed by ISO-aligned quality inspection and CAD/CAM file compatibility (STEP/DXF).

Industries and Applications Served

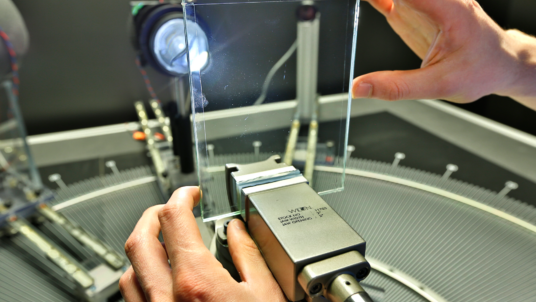

Optical and Photonics

- Substrates for laser mirrors, beam splitters, filters

- AR-coated windows and optical wafers

Medical and Biotech

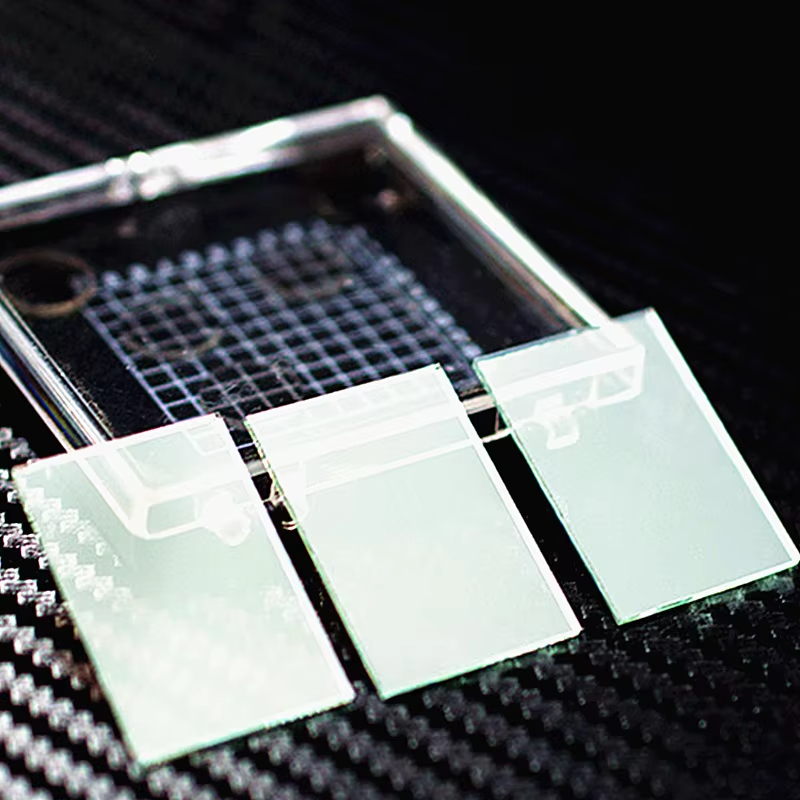

- Microfluidic chip carriers

- Diagnostic platforms with optical access

Semiconductor and MEMS

- Thin glass wafers for wafer-level packaging

- Dielectric insulating substrates

Industrial Engineering

- High-temperature viewports, inspection windows

- Transparent shields in laser and cutting systems

Aerospace and Defense

- Lightweight sensor covers and heat shields

- IR-transparent optical domes

Trusted Partner for Universities and Research Laboratories Worldwide

We proudly support universities, research institutes, and national laboratories across the globe with custom glass components tailored for advanced experimentation and scientific innovation.

Whether it’s custom-cut BOROFLOAT® 33 microscope slides, precision-coated optical substrates, or chemically stable microfluidic glass chips, our engineering team works closely with academic clients to deliver:

- Application-specific materials with exact tolerances

- Cleanroom-ready packaging and documentation

- Rapid prototyping for research validation

- Long-term supply stability for extended research programs

The BOROFLOAT®33 glass we process is widely used in spectral devices, biological imaging, laser research and material testing platforms, making us a reliable partner in the global R&D community.

People Also Ask

1. What machining services are available for Schott BOROFLOAT® 33 glass?

We offer a full range of machining services including CNC cutting, drilling, slotting, edge grinding, optical polishing, and surface coating. Thermal tempering and microhole drilling are also available.

2. Can BOROFLOAT® 33 glass be laser cut?

Yes, BOROFLOAT® 33 can be precision laser cut, especially for thin substrates. However, for thicker parts or complex geometries, CNC milling is often preferred to reduce edge chipping.

3. What are the thickness tolerances for custom BOROFLOAT® 33 substrates?

We can achieve thickness tolerances as tight as ±0.01 mm depending on the dimensions and application, especially for optical or semiconductor substrates.

4. Is it possible to drill microholes or channels into BOROFLOAT® 33 for microfluidic or sensor use?

Yes. We support micro-drilling (hole diameters <0.5mm), slotting, and channel etching suitable for microfluidics, MEMS, or sensor applications, all while maintaining structural integrity.

5. Can anti-reflective or conductive coatings be applied to BOROFLOAT® 33?

Absolutely. We offer AR coatings, ITO/FTO conductive layers, and dielectric coatings depending on your optical, electronic, or EMI shielding requirements.

6. What surface finishes are available for BOROFLOAT® 33 glass?

We provide various surface finishes including rough-cut, ground, optically polished (Ra ≤ 0.01 µm), and lapped surfaces, customizable for your intended optical or mechanical usage.

7. Can you provide chamfered or beveled edges for BOROFLOAT® 33 parts?

Yes, we offer edge finishes such as C-edge, D-edge, beveled, and safety chamfering for enhanced handling safety and precision alignment in assemblies.

8.Do you offer small batch or prototype orders?

Absolutely. We support small-batch prototyping, low MOQ orders, and fast turnaround for research institutes, OEM developers, and niche technical applications.

Available Thicknesses for Schott BOROFLOAT® 33 Glass (Custom Supply)

| Nominal Thickness (mm) | Thickness Tolerance (± mm) | Typical Application | Maximum Sheet Size (mm) |

|---|---|---|---|

| 0.11 | ±0.005 | Ultra-thin optics, microfluidics, wafers | 300 × 400 |

| 0.20 | ±0.005 | Polished substrates, bio-sensing, photonics | 300 × 400 |

| 0.30 | ±0.01 | Filter substrates, IR windows, diagnostics | 300 × 400 |

| 0.50 | ±0.01 | Optical elements, reinforced thin plates | 400 × 500 |

| 0.70 | ±0.02 | Lab glassware, furnace viewports | 400 × 500 |

| 1.10 | ±0.03 | General optical applications, laser windows | 500 × 600 |

| 2.00 | ±0.05 | Structural covers, sensor protection layers | 500 × 600 |

| 3.30 | ±0.05 | Machined parts, industrial sight glass | 600 × 800 |

| 5.00 | ±0.1 | High-load components, thermal barriers | 600 × 800 |

| 6.50 | ±0.1 | Custom panels, assembly carriers | 600 × 800 |

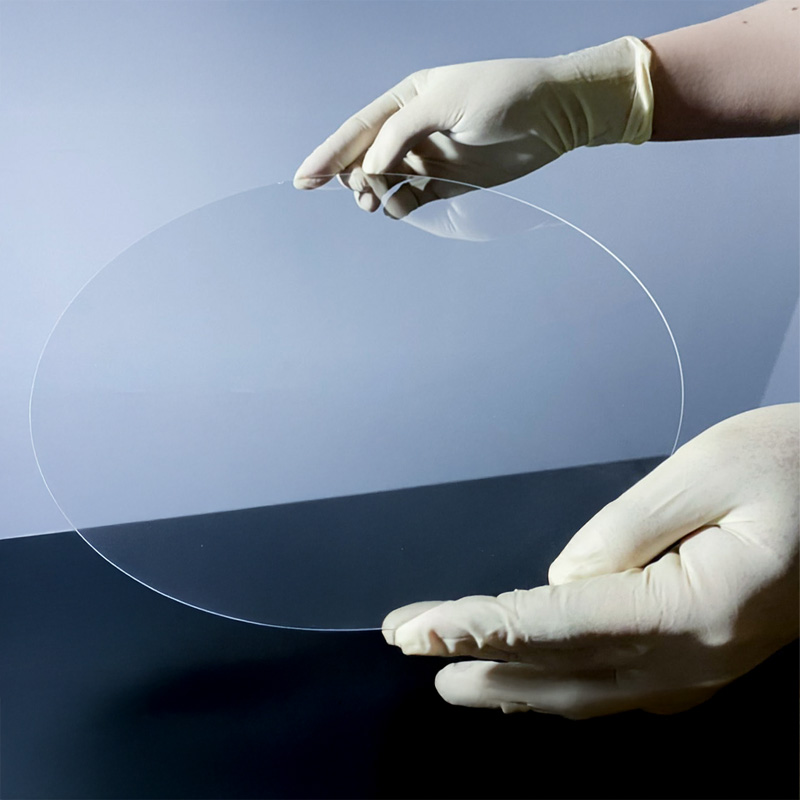

We carried out precise thinning processing using Schott BOROFLOAT® 33 glass raw materials with a thickness of 0.2mm to achieve the customized requirement of a final thickness of 0.11mm. The processing steps are as follows:

1.Grinding process

High-precision grinding equipment is used to process the 0.2mm thick BOROFLOAT® 33 original sheet through multiple procedures.

By gradually grinding and strictly controlling parameters, a highly flat glass surface is achieved to meet the requirements of optical communication and precision applications.

2.Polishing process

After entering the polishing process, advanced polishing techniques are applied to further enhance the surface finish.

Ensure that the glass is free of scratches and matte surfaces, and its light transmittance meets the optical grade requirements, making it suitable for subsequent AR coating or biological detection applications.2

3.Thickness control

Throughout the entire processing process, real-time online monitoring is carried out through high-precision non-contact thickness gauges to ensure that the final product thickness is stably controlled within the range of 0.11mm ± 0.005mm, meeting the customized specifications of the project.

Leave Your Message