产品: Corning Willow® Glass Wafers

Corning Willow® Glass Wafers

Technical Specifications – Corning Willow® Glass

| Property | Value | Unit / Notes |

|---|---|---|

| Glass Type | Ultra-thin flexible aluminosilicate | Designed for flexible electronics |

| Density | ~2.36 | g/cm³ |

| Refractive Index | ~1.51 | @ λ = 587.6 nm |

| CTE (20–300°C) | ~3.2 × 10⁻⁶ | /K, matched with silicon and OLED materials |

| Young’s Modulus | ~70 | GPa |

| Softening Point | ~800 | °C |

| Minimum Thickness | 25 | µm |

| Bend Radius | < 5 | mm (100 µm thick) |

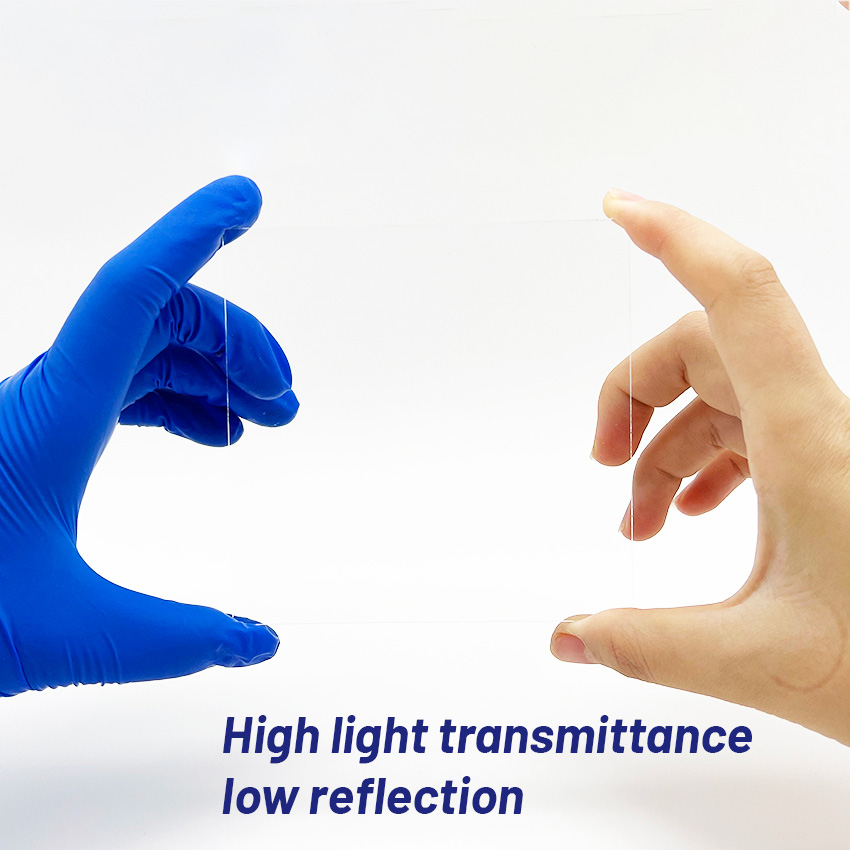

| Transmission (Visible) | >90% | 400–700 nm |

| Compliance | RoHS, REACH | Lead-free, arsenic-free |

Overview: What is Corning Willow® Glass?

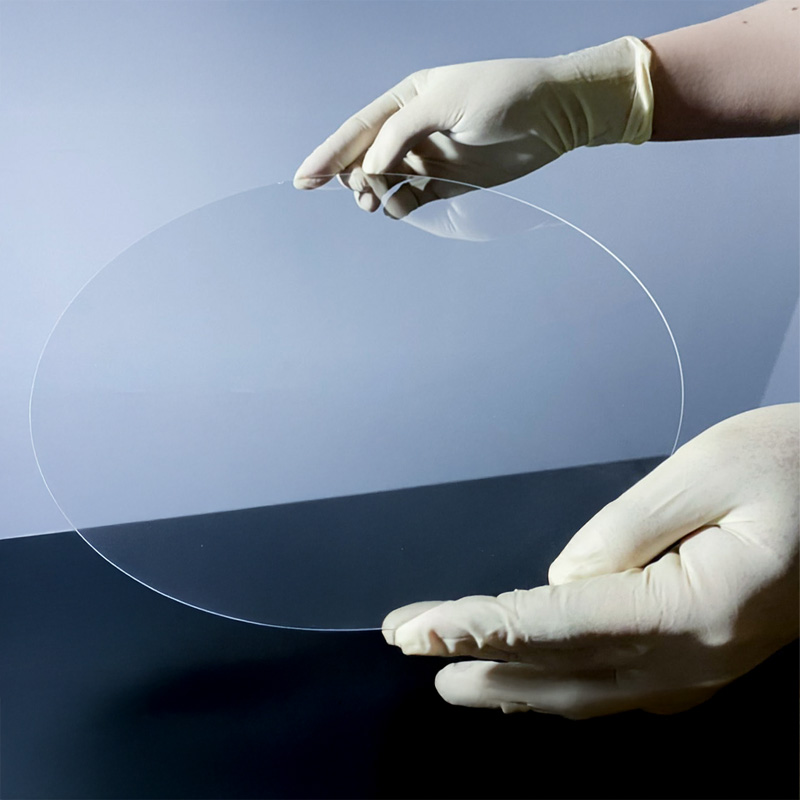

Corning Willow® Glass is a next-generation ultra-thin and flexible aluminosilicate glass designed for wearable electronics, foldable devices, and flexible displays. With thicknesses as low as 25 µm, it combines bendability with the optical and chemical performance of glass.

Unlike plastic films, Willow Glass retains excellent thermal resistance, optical clarity, and surface quality—making it ideal for flexible OLEDs, sensors, microfluidics, and R&D electronics.

Why Choose Willow® Glass Wafers for Flexible Electronics?

-

- Bendable & Durable: Down to 25 µm; maintains integrity with radius < 5 mm

-

- Highly Transparent: >90% light transmission in visible range

-

- Thermally Stable: Handles high-temperature processing (>800 °C softening point)

-

- Surface Quality: Smoother and more robust than polymer substrates

-

- Environmentally Friendly: Free of lead, arsenic, antimony; RoHS & REACH compliant

Your Trusted Willow® Wafer Supplier – TIHOT

As a factory-direct custom processor, TiHot supplies precision-fabricated Corning Willow® wafers to global display and electronics developers.

We offer:

-

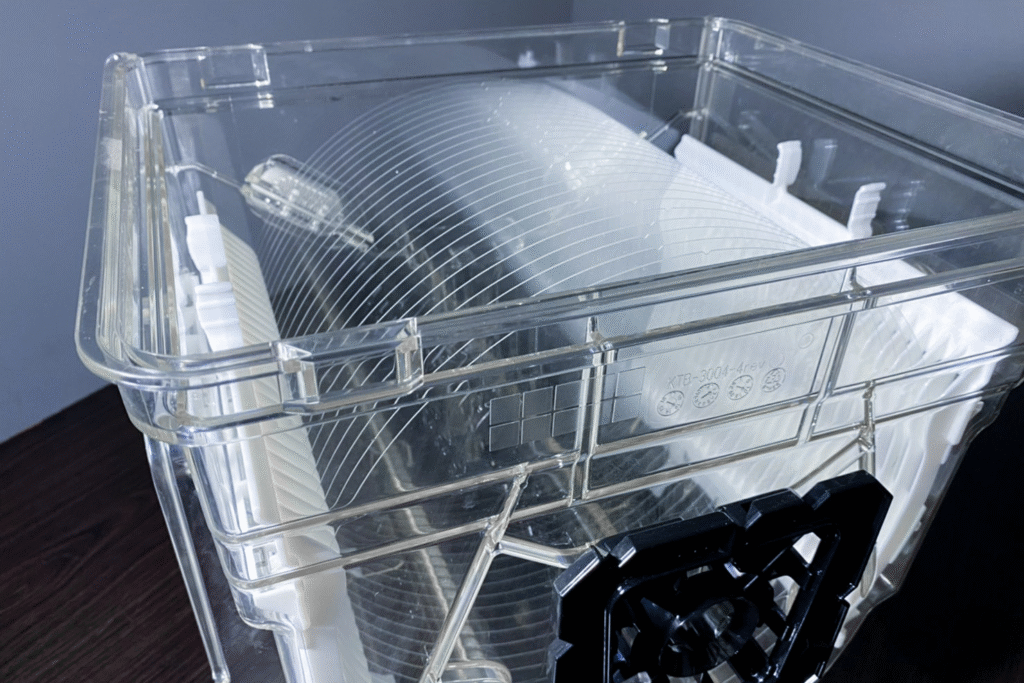

- Prototype and low-volume wafer supply

-

- CNC cutting, ultra-thin polishing, and laser micro-dicing

-

- ITO, AR, dielectric coating services

-

- Roll-to-sheet cutting for flexible device prototyping

-

- ISO-aligned QA and cleanroom packaging for every shipment

Applications of Willow® Glass Wafers

-

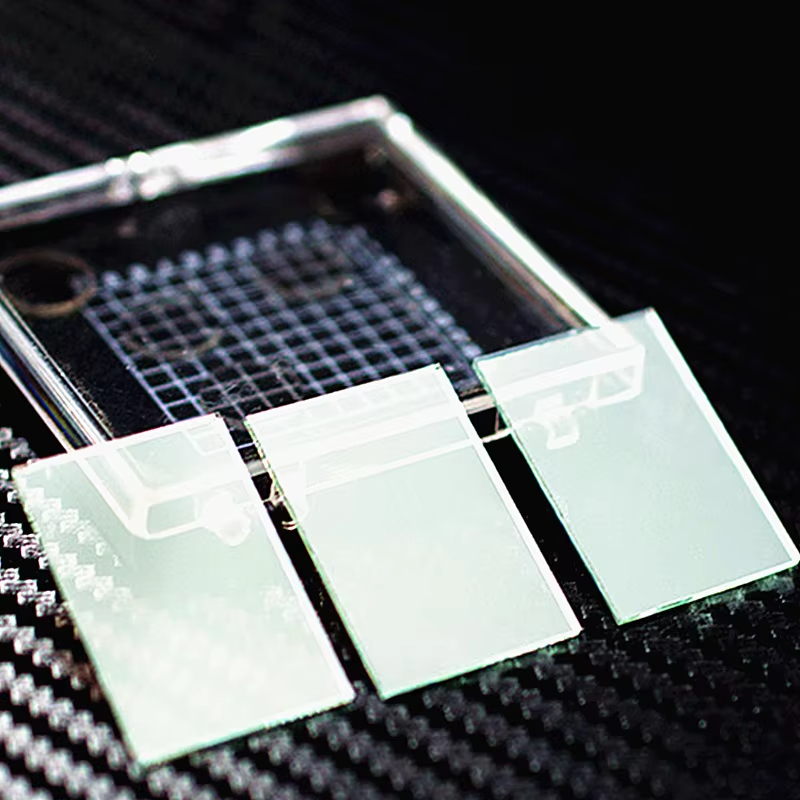

- Flexible OLED & AMOLED displays

-

- Wearable sensors and patches

-

- Foldable smartphones and tablets

-

- Bendable microfluidic chips

-

- Thin-film encapsulation base glass

-

- Research substrates for flexible electronics

People Also Ask (FAQ)

-

- What is the thinnest Willow glass wafer available? We offer Corning Willow® wafers as thin as 25 µm, with flexibility suitable for rollable and wearable applications.

-

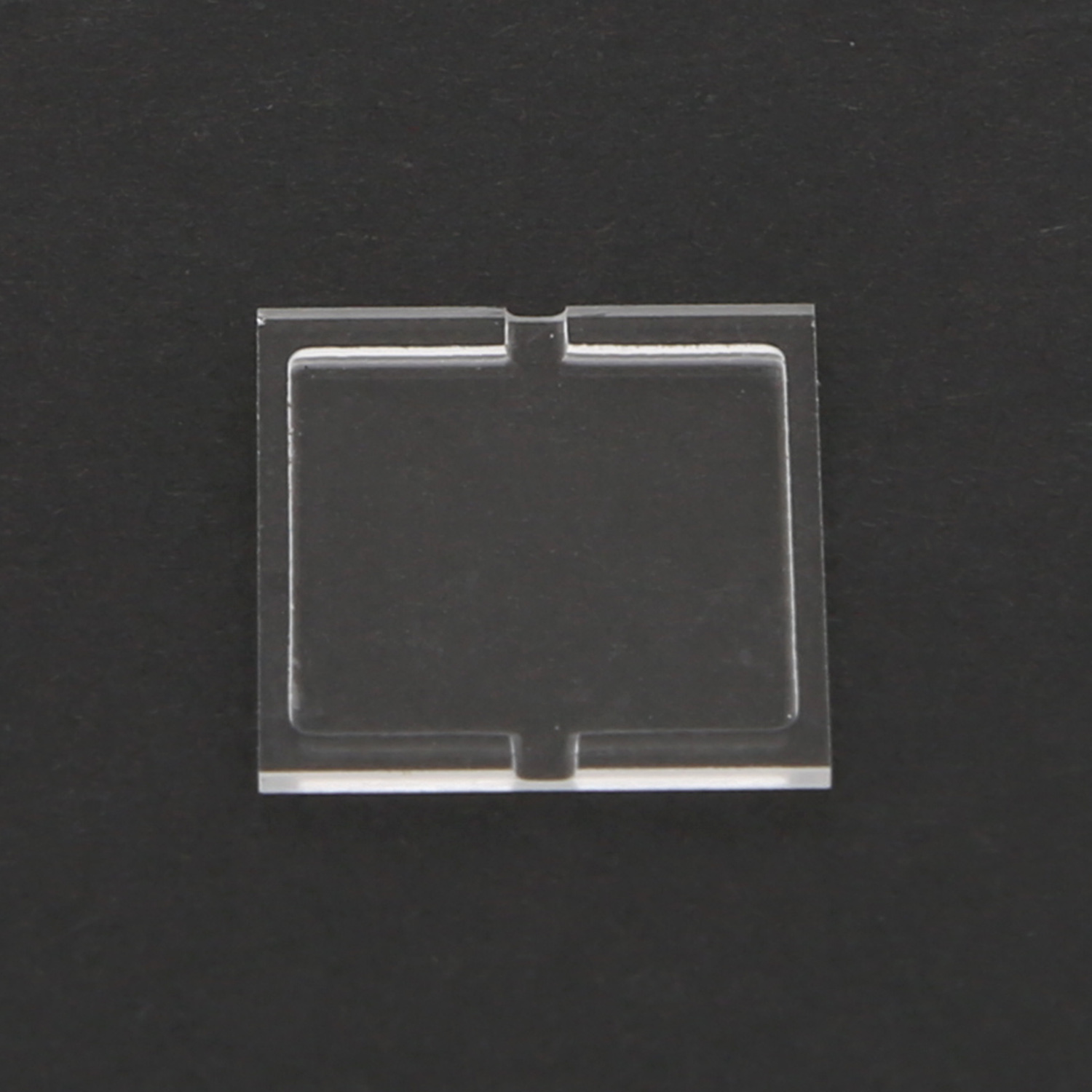

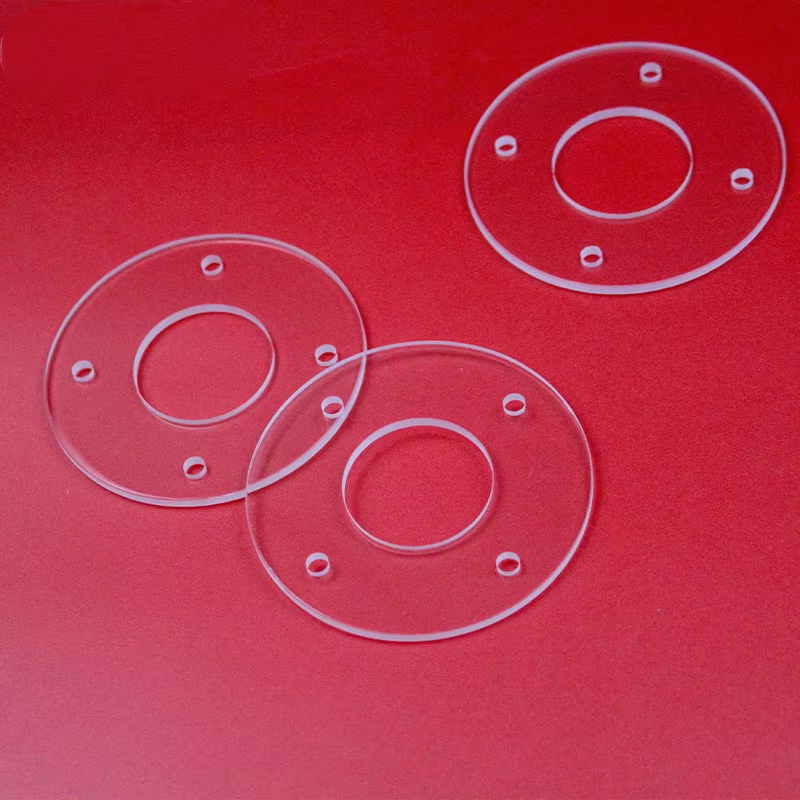

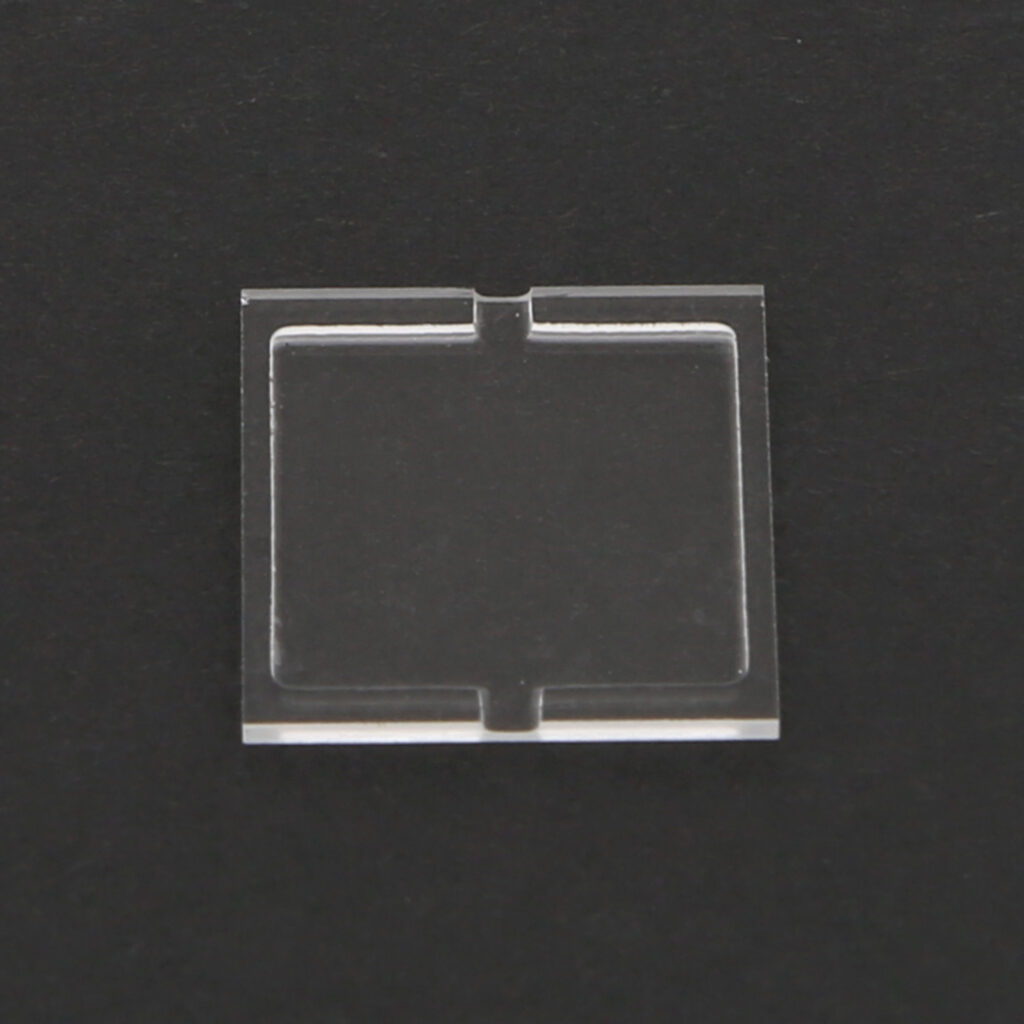

- Can Willow wafers be laser cut or slotted without breakage? Yes. We support precision laser cutting, CNC dicing, and edge finishing optimized for ultra-thin flexible glass.

-

- Do you provide coatings on Willow glass wafers? Absolutely. We offer ITO, FTO, AR, and dielectric coatings for electronics, display, and sensor applications.

Customizable Willow® Wafer Dimensions

| Parameter | Custom Range | Notes |

|---|---|---|

| Shape | Round / Square / Roll-cut | Roll-to-sheet formats supported |

| Diameter (Round) | 20 mm – 200 mm | 2″, 4″, 6″ wafers standard |

| Thickness | 25 µm – 200 µm | Ultra-thin for flexible use |

| Thickness Tolerance | ±0.01 mm – ±0.05 mm | Based on thickness & area |

| Edge Options | Ground / Chamfered | For safe handling and alignment |

| Surface Finish | Polished / Optical / Coated | Ra ≤ 0.01 µm available |

| Coating Options | ITO / FTO / AR / Dielectric | For electronics, sensors, EMI shielding |

| Packaging | Protective film / Cleanroom sealed | Scratch-free, bend-safe handling |

Leave Your Message