Quartz glass, known for its purity, thermal stability, and wide spectral transparency, has become an indispensable material across a wide range of high-tech industries. This guide explores the key properties of quartz glass, compares fused quartz and fused silica, and highlights the most important applications—from semiconductor fabrication to precision optics.

1. What Is Quartz Glass?

Quartz glass refers to a group of materials derived from high-purity silicon dioxide (SiO₂), either naturally mined (quartz) or synthetically produced (fused silica). It is an amorphous, non-crystalline material characterized by:

- Exceptional chemical purity

- Broad optical transparency (UV to IR)

- Excellent thermal stability

- High mechanical strength

- Low coefficient of thermal expansion

These characteristics make quartz glass uniquely suited for demanding environments and precision applications.

2. Quartz Glass vs. Fused Silica: What’s the Difference?

While the terms are often used interchangeably, there are key differences between fused quartz and fused silica:

| Property | Fused Quartz | Fused Silica |

|---|---|---|

| Source | Natural quartz crystal | Synthetic silicon dioxide |

| Manufacturing Method | Melting of quartz crystal | Flame hydrolysis of silicon tetrachloride (SiCl₄) |

| Purity | High | Ultra-high |

| Structure | Amorphous | Amorphous |

| UV Transmission | Good | Excellent |

| Radiation Resistance | High | Very High |

| Cost | Lower | Higher |

3. Key Properties of Quartz Glass

3.1 Thermal Stability

Quartz glass maintains dimensional and structural integrity at extreme temperatures, with continuous use up to 1100°C and short-term resistance up to 1300°C. Its low thermal expansion prevents cracking due to thermal shock.

3.2 Wide Optical Transparency

Quartz glass is transparent across a wide spectral range—from deep UV (~200 nm) to IR (~3 μm)—making it ideal for optics, lasers, and photonics.

3.3 Chemical and Electrical Resistance

Quartz glass resists most acids and chemical agents, and its high dielectric strength makes it an excellent insulator in electronic and high-voltage systems.

3.4 Mechanical Strength

With high hardness and moderate impact resistance, quartz glass can withstand mechanical stress in dynamic environments like semiconductor etching chambers and optical setups.

4. Industrial Applications

Quartz glass plays a critical role in enabling innovation across advanced industries:

4.1 Semiconductor Manufacturing

Used in diffusion tubes, wafer carriers, and furnace components, quartz glass withstands high temperatures and maintains purity in semiconductor processing.

4.2 Precision Optics and Photonics

Its optical clarity and UV transmission make quartz glass essential for lenses, prisms, mirrors, laser windows, and UV photolithography.

4.3 Medical and Life Sciences

Quartz glass is used in UV sterilization systems, biosensor substrates, and microfluidic devices, where biocompatibility and transparency are vital.

4.4 Aerospace and Defense

Quartz windows and domes are used in IR and UV detection systems for satellites, aircraft, and defense optics.

4.5 Renewable Energy

Quartz glass protects solar cells and UV curing lamps, providing high transmission and resistance to environmental degradation.

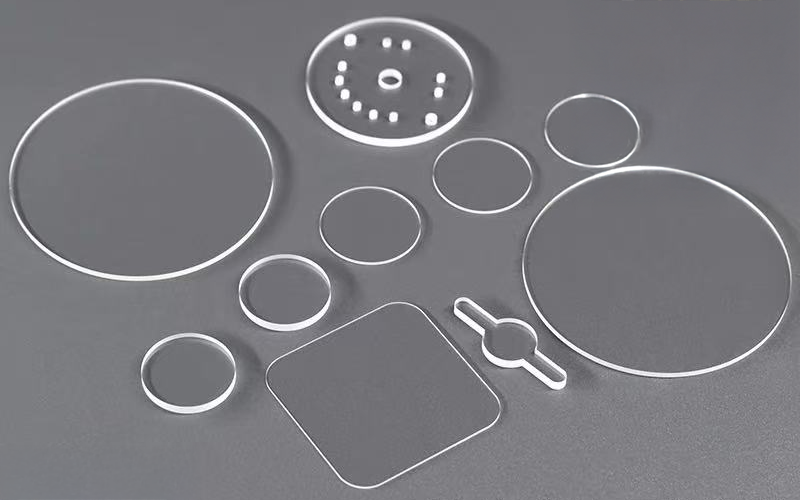

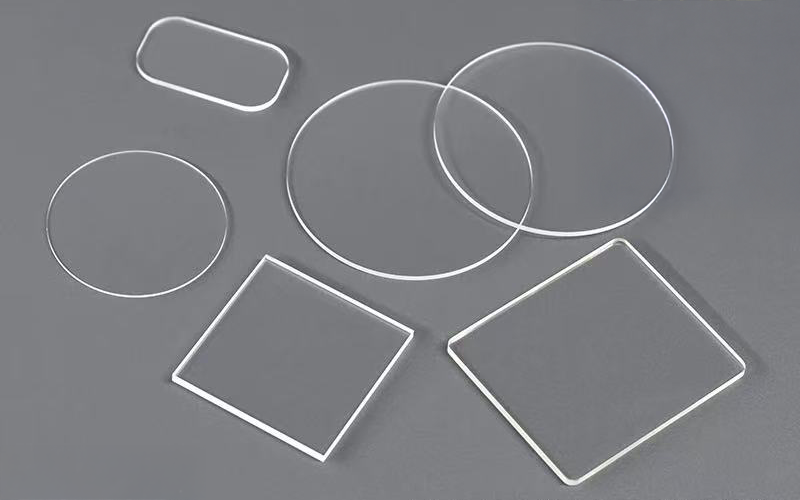

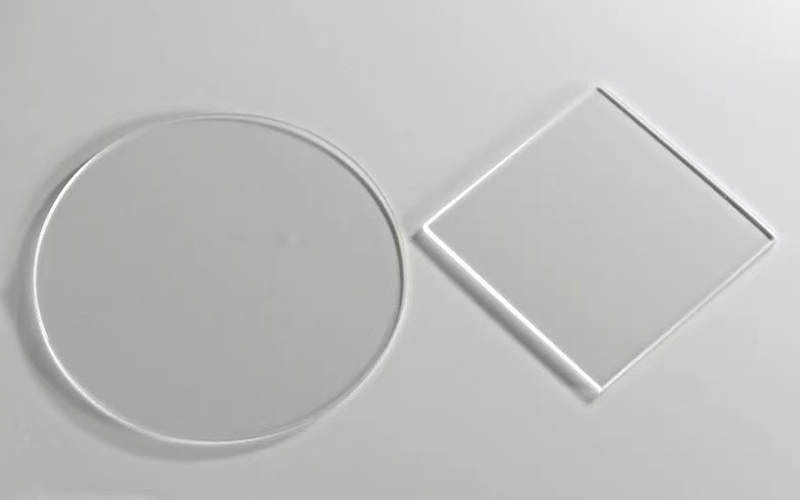

5. Form Factors and Customization

Quartz glass is available in diverse shapes and can be custom machined to meet project-specific requirements:

- Quartz glass sheets (cut to size, polished, coated)

- Quartz rods and tubes

- Quartz wafers for MEMS and optics

- Quartz optical components (windows, covers, domes)

- CNC-fabricated precision structures

Custom cut quartz glass can be polished, drilled, coated, or bonded depending on the end-use application.

6. Advanced Processing Enhancing Quartz Glass Performance

To meet modern performance standards, quartz glass often undergoes precision fabrication using:

- CNC micromachining for ultra-fine cuts and microstructures

- Surface polishing and AR coatings for optical enhancement

- Laser drilling for high-aspect-ratio holes

- UV and plasma cleaning for contaminant removal

These techniques extend the material’s utility in photonics, microelectronics, and quantum research.

7.Common Grades of Quartz Glass

Quartz glass is available in several industrial grades depending on its transmission spectrum, production method, and intended application. Below is an overview of common Chinese domestic designations:

| Grade | UV Transmission | Bubble Content | Optical Clarity | Key Applications |

|---|---|---|---|---|

| JGS1 | Excellent (Deep UV, <200nm) | Very low | High | UV lithography, laser optics, scientific instruments |

| JGS2 | Good (Mid-UV, ~220nm) | Low | Moderate | UV lamps, general optics, analytical instruments |

| JGS3 | Limited (Visible to IR only) | Higher | Lower | Infrared windows, furnace observation, general glass use |

- JGS1 (Optical Grade Fused Silica)

Made by synthetic gas-phase method. Offers excellent transmittance from deep UV to near-IR. Low OH content and high homogeneity. Used in excimer lasers, semiconductor optics, and high-end photonics. - JGS2 (General UV Quartz Glass)

Made by melting natural quartz. Suitable for UV applications that do not require ultra-high transmission. Often used in UV curing and disinfection. - JGS3 (IR Quartz Glass)

Does not transmit UV light, but performs well in visible and IR ranges. More cost-effective. Used for heating tubes, IR windows, and general viewing ports.

How to Choose the Right Quartz Glass Grade?

Choosing between JGS1, JGS2, and JGS3 depends on:

- Required optical transmission range (UV, VIS, IR)

- Desired surface quality and homogeneity

- Resistance to thermal shock and chemical exposure

- Application-specific certifications (e.g. laser use, cleanroom, medical)

8. Future Potential of Quartz Glass

With advances in nanofabrication, integrated photonics, and quantum computing, quartz glass continues to evolve. Trends include:

- Smart coatings (anti-reflective, hydrophobic, conductive)

- Integration with silicon photonics

- Radiation-hardened glass for space exploration

- Low-loss optical platforms for quantum sensors

Conclusion

Quartz glass is more than just a high-performance material—it’s a foundational element in the progress of optical, electronic, and scientific technologies. Its balance of thermal resistance, optical clarity, purity, and mechanical strength positions it as a critical enabler of innovation.

Whether you’re designing next-gen optics, semiconductor devices, or scientific instrumentation, quartz glass offers unmatched performance, reliability, and customization potential.