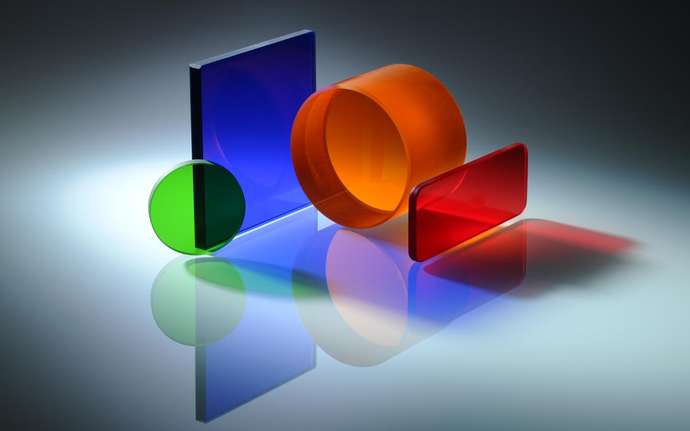

Optical glass forms the foundation of nearly every modern photonic and imaging system—from high-power lasers and scientific instruments to consumer displays and biomedical diagnostics. With dozens of materials developed by world-class manufacturers such as SCHOTT, Corning, Hoya, and Ohara, choosing the right glass for a given application requires deep technical understanding.

This article provides a comprehensive overview of the most widely used types and grades of optical glass, including their properties, performance specs, and real-world applications across industries.

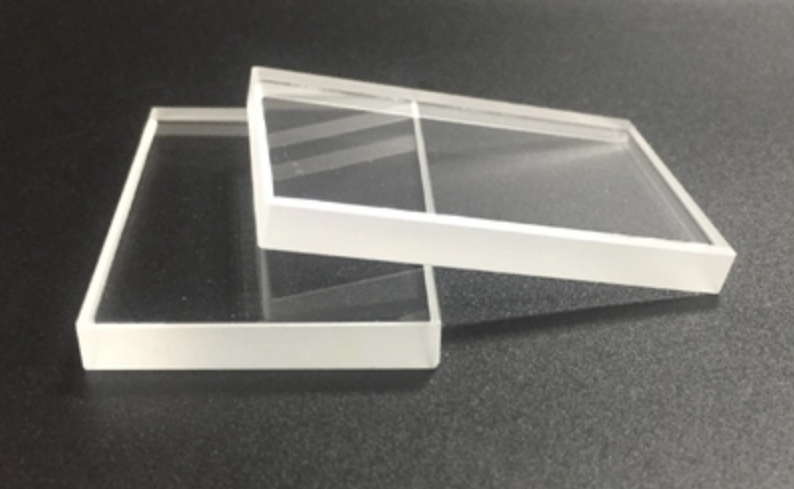

1. Technical Borosilicate Glasses

SCHOTT BOROFLOAT® 33

- Type: Borosilicate float glass

- Thermal Expansion: 3.25 × 10⁻⁶/K

- Transparency: High in VIS/NIR

- Use Cases: Microfluidic chips, optical windows, beam splitters, lab-on-chip, carriers for lithography

- Notes: Excellent chemical resistance, thermal shock resistance, optically flat

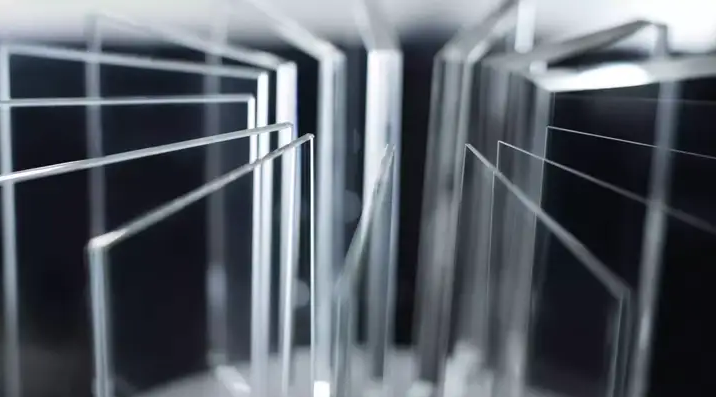

2. Display-Grade and Thin-Substrate Glasses

Corning EAGLE XG®

- Type: Alkali-free aluminosilicate glass

- Use Cases: TFT-LCD, OLED, ITO/FTO coatings, flexible circuit integration

- Features: RoHS compliant (lead/arsenic-free), ultra-flat, excellent for photolithography

- Thickness Range: 0.3–1.3 mm

Corning D263T®

- Type: Ultra-thin borosilicate

- Thickness Range: 0.1 mm – 1.1 mm

- Use Cases: Camera modules, microfluidics, AR coatings, mobile device optics

- Benefits: Scratch-resistant, optically clear, ideal for wafer-level integration

3. General-Purpose Optical Crown Glasses

N-BK7 (SCHOTT) / H-K9L (Hoya)

- Type: Borosilicate crown glass

- Refractive Index (nd): 1.5168

- Abbe Number: 64.17

- Use Cases: Lenses, prisms, windows, beam splitters

- Notes: Excellent balance of performance and cost, widely available

SCHOTT B270

- Type: Soda-lime crown glass

- Transparency: >91% in visible range

- Use Cases: Spectroscopy cuvettes, optical windows, general optics

- Strengths: Cost-effective, good polishability

4. High Refractive Index Glasses

SF Series (e.g., SCHOTT SF2, SF10)

- Type: Dense flint glass

- Index Range: 1.6 – 1.8+

- Use Cases: Compact lens systems, microscopes, zoom modules

- Strengths: High dispersion for aberration control, used in complex designs

5. Low Dispersion Glasses for Color Correction

FPL51 (SCHOTT) / H-FPL51 (Hoya) / S-FPL53 (Ohara)

- Type: Fluorophosphate glass

- Features: Low dispersion, moderate index

- Use Cases: Apochromatic triplet lenses, ED objectives, astro-optics

- Notes: Critical for color correction in high-resolution systems

6. UV and Deep UV Grade Glass

Fused Silica (e.g., JGS1, Suprasil®)

- Transmission: From 180 nm (UV) to 3 µm (IR)

- Benefits: Ultra-high purity, high thermal stability, radiation resistance

- Use Cases: Excimer lasers, UV photolithography, space optics

7. IR and Specialty Laser Glasses

| Material | Spectral Range | Application |

|---|---|---|

| ZnSe | 0.6–16 µm | CO₂ laser optics, IR sensors |

| Germanium (Ge) | 2–14 µm | Thermal imaging, surveillance lenses |

| CaF₂ | 0.13–9 µm | UV lasers, UV/VIS optics, spectroscopy |

| Sapphire | 0.15–5.5 µm | IR windows, laser domes, high-durability optics |

8. Summary Comparison Table

| Glass Type | Key Feature | Refractive Index (nd) | Abbe Number (Vd) | Typical Use |

|---|---|---|---|---|

| N-BK7 / H-K9L | Balanced crown glass | 1.5168 | 64.17 | Lenses, prisms, windows |

| SF10 | High-index flint glass | 1.728 | 28.41 | Compact optics, microscopes |

| FPL51 / S-FPL53 | Low dispersion ED glass | 1.497 | 81.6+ | Color-corrected lenses |

| D263T | Ultra-thin glass | ~1.52 | ~60 | Camera modules, thin wafers |

| BOROFLOAT® 33 | Borosilicate, low expansion | 1.47 | ~64 | Substrates, covers, microfluidics |

| EAGLE XG® | Flat display glass | 1.51 | ~60 | TFT substrates, OLED backplanes |

| Fused Silica (JGS1) | UV-grade, low expansion | 1.458 | ~67 | Laser optics, UV systems |

9. Key Considerations When Choosing Optical Glass

When specifying optical glass for a project, engineers must balance:

- Refractive index & dispersion (optical design parameters)

- Thermal and chemical resistance (operating environment)

- UV/IR transmission (spectral performance)

- Surface quality and polishability (precision optics)

- Cost and availability (project scale)

Conclusion

From Schott BOROFLOAT® 33 and Corning EAGLE XG® to ultra-thin D263T and low-dispersion FPL51, the modern optical design engineer has access to a vast toolkit of specialized materials. Each glass type addresses unique performance needs—from thermal stability and UV transparency to micro-patternability and environmental durability.

Whether you’re designing a biophotonic sensor, high-energy laser system, or semiconductor lithography mask, choosing the right grade of optical glass is critical to long-term performance and system integrity.