Optical glass is the fundamental building block of modern photonics, serving as the core component in everything from the lenses of a smartphone camera to the complex optics within a surgical microscope. The performance of these devices is entirely dependent on the specific physical properties of the glass used. To design or source the right material, it’s crucial to understand key optical glass properties: refractive index, Abbe number, and optical transmission. This guide provides an in-depth, yet easy-to-understand, look at these properties, their significance, and how they apply to various high-tech applications.

What is Refractive Index in Optical Glass?

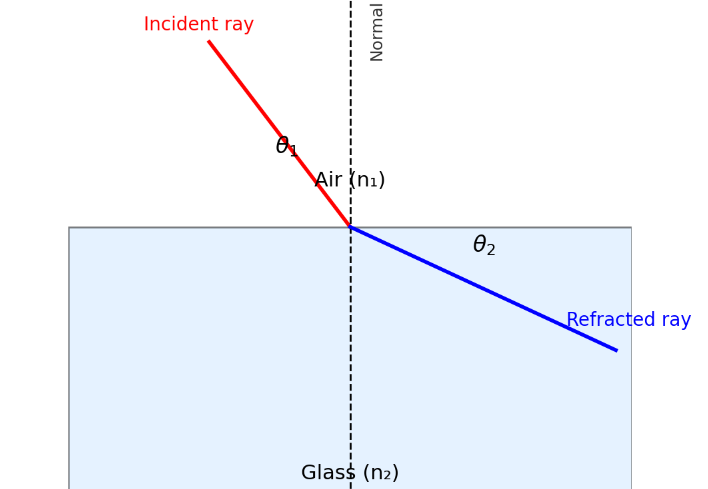

The refractive index (n) is arguably the most important property of any optical glass. It is a dimensionless number that describes how light propagates through a medium. In simple terms, it’s a measure of how much a ray of light is bent, or refracted, when it passes from one medium to another (e.g., from air into glass).

How does Refractive Index Affect Light Bending?

When light enters an optical material, its speed changes. This change in speed causes the light path to bend. A higher refractive index indicates that light travels more slowly through the material, resulting in a greater degree of bending.

How is Refractive Index Measured?

The refractive index of optical glass is typically measured using a refractometer at a specific wavelength of light. Standard measurements are often taken at the sodium D-line (587.6 nm), but a full characterization includes measurements across a range of wavelengths to determine the glass’s dispersion properties.

For more on specific materials, see our detailed pages on Fused Silica or Borofloat 33, which have a low refractive index.

What is the Abbe Number and Why is it Important?

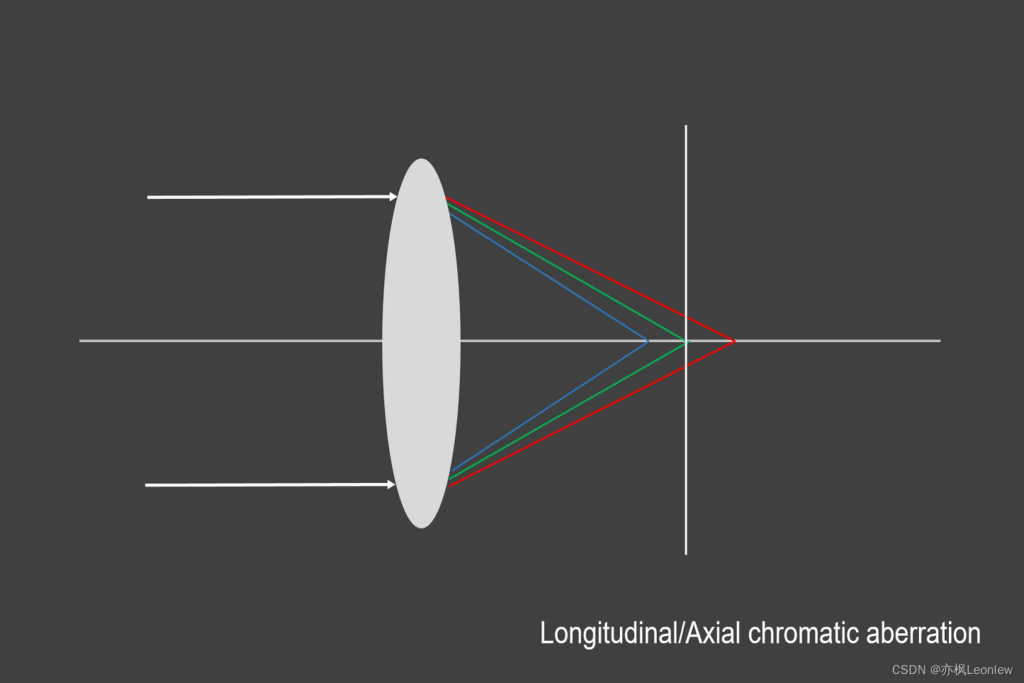

While the refractive index describes how light bends at a single wavelength, the Abbe number (Vd) describes how much the refractive index of a glass changes across a spectrum of wavelengths. This property is known as dispersion.

The Abbe number is an inverse measure of dispersion:

- High Abbe number: Low dispersion. The refractive index changes very little with wavelength. This glass is known as “crown glass.”

- Low Abbe number: High dispersion. The refractive index changes significantly with wavelength. This glass is known as “flint glass.”

How does Abbe Number Relate to Chromatic Aberration?

Chromatic aberration is an optical defect that occurs when a lens fails to focus all colors (wavelengths) of light at the same point. This results in a blurry image with color fringes. Since different wavelengths bend at different angles, a lens with high dispersion (low Abbe number) will exhibit significant chromatic aberration

Frequently Asked Questions about Optical Glass

Q: What is the difference between optical glass and regular glass?

A: Regular glass, like window glass, is not designed for imaging and has a lower degree of purity and homogeneity. Optical glass is specially manufactured to be highly pure, free of defects like bubbles or streaks, and to have precisely controlled optical properties (refractive index, dispersion, and transmission).

Q: How is the quality of optical glass measured?

A: The quality is measured against various standards, including ISO 10110 for optical drawings, and MIL-PRF-13830B for surface quality. Key metrics include refractive index tolerance, Abbe number, bubble and inclusion content, and surface flatness and parallelism.

.Q: What is optical homogeneity?

A: Optical homogeneity refers to the uniformity of the refractive index throughout a piece of glass. Non-uniformity can cause light rays to be bent inconsistently, leading to distorted images. High-quality optical glass has an exceptionally high degree of homogeneity, which is crucial for high-resolution imaging systems.

Q: What is the main benefit of high refractive index glass?

A: The main benefit is that it allows for the design of thinner, more compact lenses for a given optical power. This is particularly valuable for applications where weight and size are critical, such as in consumer electronics and aerospace optics.

Contact Our Optical Glass Experts Today

Ready to bring your next project to life? Whether you need a single custom optical glass wafer for prototyping or a large-scale production run of precision substrates, our team is here to help. Our expertise in material properties, manufacturing processes, and quality control ensures you get the exact optical components you need.