Understanding the fundamental differences between hydrophobic and hydrophilic surfaces is crucial for selecting the right coating technology for your glass applications. Whether you’re developing optical components, automotive glazing, or architectural glass systems, the choice between water-repelling and water-attracting properties directly impacts performance, maintenance, and user experience.

What Do “Hydrophobic” and “Hydrophilic” Mean?

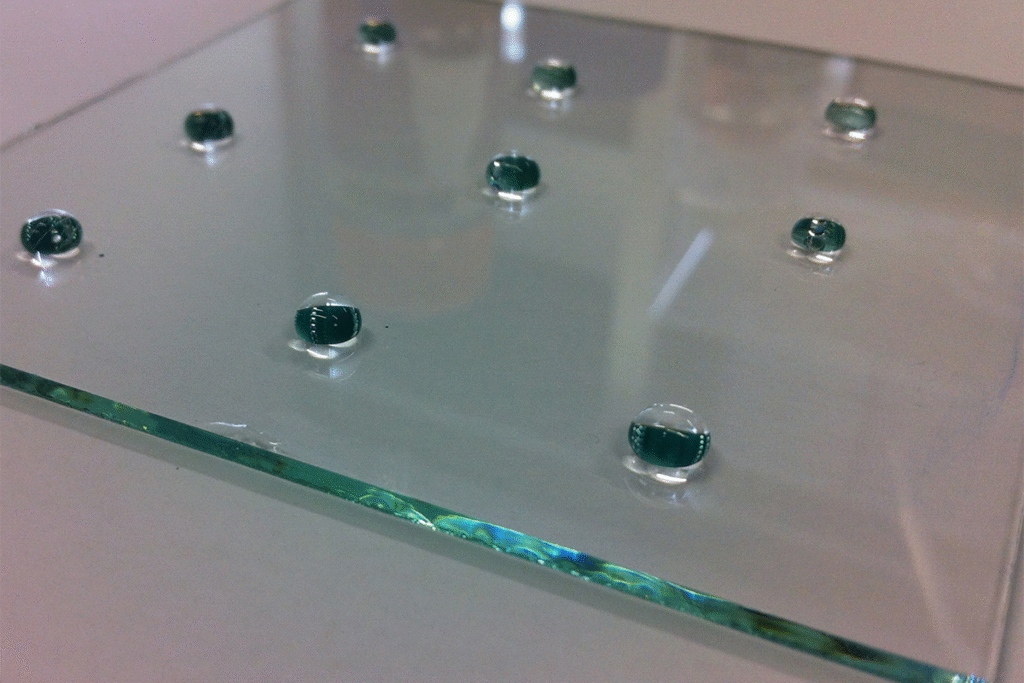

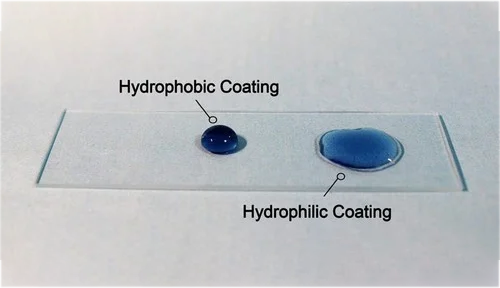

The terms hydrophobic and hydrophilic describe how surfaces interact with water molecules, fundamentally determined by surface energy and molecular structure. Hydrophobic surfaces exhibit low surface energy, causing water to form discrete droplets that minimize contact with the surface. Conversely, hydrophilic surfaces possess high surface energy, allowing water to spread uniformly across the surface.

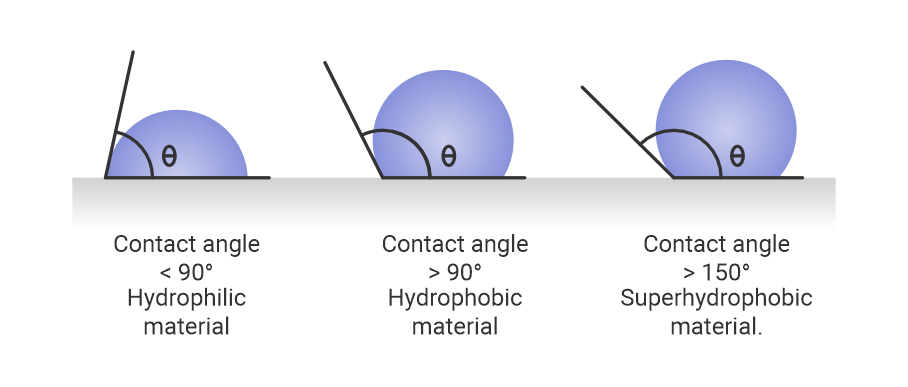

The industry standard for quantifying these properties is the water contact angle (WCA), measured using standardized protocols:

- Hydrophobic surfaces: WCA > 90°, with water forming distinct beads

- Superhydrophobic surfaces: WCA > 150°, achieving near-perfect water repellency

- Hydrophilic surfaces: WCA < 90°, promoting water spreading

- Superhydrophilic surfaces: WCA ≈ 0–10°, enabling complete water film formation

These contact angle thresholds serve as critical design parameters when specifying coating requirements for different applications. Understanding these fundamentals enables engineers to make informed decisions about surface modification strategies.

Hydrophobic vs Hydrophilic Glass Coatings: Technologies & Mechanisms

Hydrophobic Systems: Silane and Fluoropolymer Technologies

Hydrophobic coatings typically employ fluorosilane chemistry or fluoropolymer matrices to create low-energy surfaces. Fluorosilane treatments form self-assembled monolayers (SAMs) through chemical bonding with glass hydroxyl groups, providing durable water repellency with minimal thickness impact. These coatings excel in self-cleaning applications and contamination resistance.

Fluoropolymer-based systems offer enhanced durability and chemical resistance but may require primer layers for optimal adhesion. Sol-gel processes enable precise control over coating thickness and uniformity while accommodating various substrate geometries.

Hydrophilic Systems: Photocatalytic and Wetting Layers

Hydrophilic coatings often utilize titanium dioxide (TiO₂) photocatalytic layers that provide both anti-fogging properties and self-cleaning capabilities under UV exposure. These coatings work by breaking down organic contaminants while maintaining superhydrophilic behavior.

Alternative hydrophilic systems include plasma-treated surfaces and hydrogel-based coatings that maintain water-attracting properties through polar functional groups. These treatments enable rapid water spreading, preventing fog formation on optical surfaces.

Oleophobic (AF) vs Hydrophobic Differences

While hydrophobic coatings repel water effectively, oleophobic (anti-fingerprint) treatments target both water and oil-based contaminants. AF coatings typically employ specialized fluorochemistry to achieve low surface energy against both polar and non-polar liquids. This distinction becomes critical for touch-screen applications and high-traffic glass surfaces where fingerprint resistance matters more than simple water repellency.

Hydrophobic vs Hydrophilic: Pros & Cons by Use Case

Selecting between hydrophobic and hydrophilic treatments requires careful consideration of primary application requirements, environmental conditions, and maintenance protocols.

| Property | Hydrophobic Coatings | Hydrophilic Coatings | Key Applications |

| Water behavior | Beading & rolling off | Uniform spreading | Self-cleaning vs Anti-fog |

| Cleaning frequency | Reduced (self-cleaning) | Moderate (rinse-effective) | Outdoor glass vs Optical lens |

| Optical clarity | Excellent when clean | Consistent in humidity | Display vs Bathroom mirror |

| Durability | UV/chemical sensitive | Photo-stable (TiO₂) | Automotive vs Marine |

| Maintenance strategy | Avoid harsh detergents | Compatible with surfactants | Residential vs Commercial |

The choice between systems depends heavily on whether the primary concern involves contamination accumulation or fog prevention. Hydrophobic coatings excel in dusty environments where particle shedding matters most, while hydrophilic treatments prove superior in high-humidity conditions where fog prevention takes priority.

Hydrophobic vs Hydrophilic: Application Scenarios

Different industries favor specific surface treatments based on their unique operational requirements and performance criteria, from optical lens clarity to solar cover glass efficiency.

Optical & Display Applications

Precision optical lens systems and display cover glass typically require multi-functional coating stacks that combine anti-reflective (AR) and anti-fingerprint (AF) properties. For these applications, oleophobic AF coatings prove more valuable than simple hydrophobic treatments because they resist both water spots and fingerprint oils while maintaining optical clarity.

Display applications benefit from AF/AR layered systems where the coating sequence follows: Glass → Hardcoat → AR layers → AF top coat. This stacking approach optimizes both optical transmission and surface functionality, with contact angles typically maintained at 110-130° for effective fingerprint resistance without compromising display visibility.

Automotive & Outdoor Glass Systems

Automotive applications present varied requirements depending on the specific glass component. Automotive mirror and headlamp systems often benefit from hydrophilic anti-fog coatings to prevent condensation formation that impairs visibility and safety. These applications typically target contact angles below 30° to ensure rapid water film formation.

Conversely, windshield and side window applications may favor hydrophobic treatments where water beading improves visibility during rain conditions. Architectural glass and curtain wall systems typically employ hydrophobic coatings to reduce maintenance frequency and preserve aesthetic appearance over extended outdoor exposure periods.

Microfluidics & Laboratory Glassware

Microfluidic devices and laboratory glassware applications require precise fluid spreading and wetting control. These systems typically demand hydrophilic treatments that ensure uniform liquid distribution and eliminate air bubble entrapment that can compromise measurement accuracy.

Cell culture vessels, diagnostic equipment, and analytical glassware benefit from controlled wetting properties that enhance liquid handling precision. Superhydrophilic treatments with contact angles approaching 5-15° provide optimal performance for applications requiring complete surface wetting and precise fluid management.

Solar & Photonic Applications

Solar cover glass systems require careful surface treatment selection based on local environmental conditions and cleaning infrastructure. In low-dust environments, hydrophilic coatings can maintain consistent light transmission through uniform dirt layer formation that enables effective rinse-cleaning protocols.

However, in dusty climates with limited water access, hydrophobic treatments may provide better long-term performance by promoting particle shedding during natural rainfall. The choice impacts both energy generation efficiency and maintenance cost structures, making environmental assessment crucial for optimal system design.

FAQ

Is hydrophilic coating the best choice for anti-fog applications?

Hydrophilic coatings excel in anti-fog applications because they prevent water droplet formation by promoting uniform film spreading. However, the optimal choice depends on specific conditions—photocatalytic TiO₂ coatings provide both anti-fog and self-cleaning properties, while simple wetting agents may suffice for indoor applications.

Hydrophobic vs oleophobic: which performs better against fingerprints?

Oleophobic (anti-fingerprint) coatings outperform simple hydrophobic treatments for fingerprint resistance because they repel both water and oil-based contaminants. AF coatings use specialized fluorochemistry to achieve low surface energy against multiple liquid types, making them essential for touch-screen and high-contact applications.

Can AR, AF, and hydrophobic coatings be layered together?

Multi-layer coating systems can combine AR, AF, and surface modification properties, but require careful design to ensure compatibility. The typical stack sequence places hardcoat nearest the substrate, followed by AR layers, with AF/hydrophobic treatments as the top layer. Thermal processing and chemical compatibility between layers determine system feasibility.

How long do these coatings last outdoors and what maintenance do they require?

Coating durability varies significantly with chemistry and environmental exposure. Fluorosilane treatments may last 1-2 years outdoors, while sol-gel systems can achieve 5-10 year performance. TiO₂ photocatalytic coatings often provide 10+ year durability due to UV stability. Maintenance requirements include avoiding abrasive cleaners for hydrophobic systems and using appropriate surfactants for hydrophilic treatments.

Regular performance monitoring through contact angle measurement helps optimize replacement timing and maintain specification compliance throughout the coating lifecycle.