Measuring glass flatness requires extraordinarily precise techniques, since we’re often dealing with deviations measured in fractions of the wavelength of light. Here are the primary methods:

Interferometry: The Gold Standard

Optical interferometry is the most accurate and widely used method for measuring glass flatness. This technique exploits the wave nature of light to create interference patterns that reveal surface irregularities with nanometer-scale precision.

How it works:

An interferometer directs a beam of monochromatic light (usually from a laser or filtered lamp) toward the test surface. The light splits into two paths—one reflects off a reference surface of known flatness, while the other reflects off the test surface. When these beams recombine, they create an interference pattern of bright and dark bands called fringes.

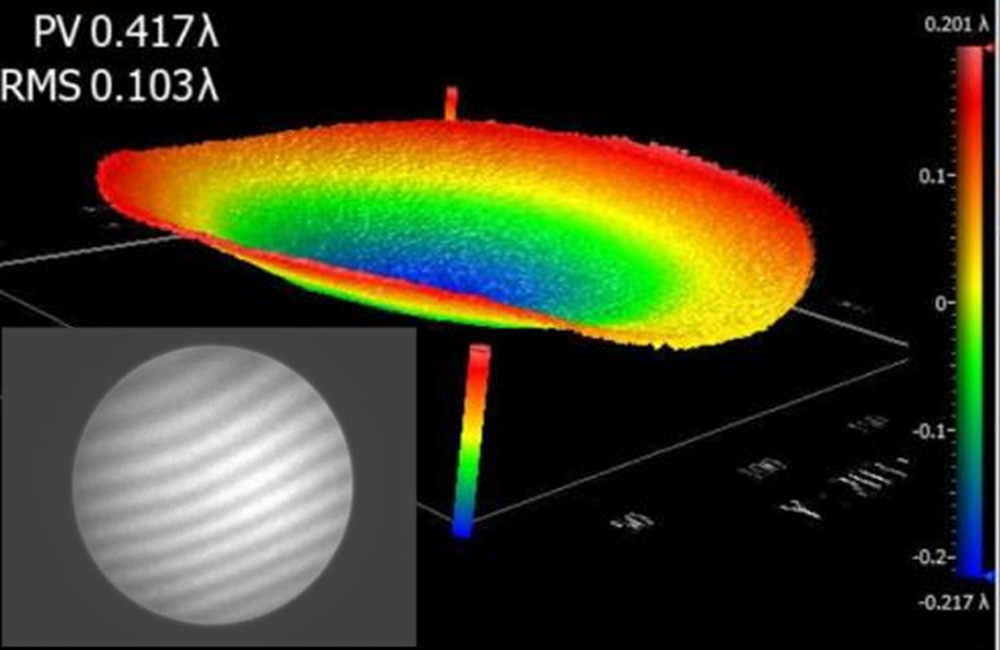

These fringes are essentially contour maps of the surface. Where the surface is perfectly flat and parallel to the reference, you’ll see uniform illumination. Any deviation from flatness creates curved, circular, or irregular fringe patterns. Each fringe represents a height change of half a wavelength of the light being used.

For example, using green light with a wavelength of 550 nanometers, each fringe indicates a 275-nanometer change in surface height. By analyzing the fringe pattern—counting fringes and measuring their spacing and curvature—technicians can create a detailed map of surface deviations.

Fizeau interferometers are particularly popular in optical manufacturing. They place the test surface in direct contact or near-contact with a reference flat, producing high-contrast fringes that are easy to interpret. Modern systems incorporate CCD cameras and computer analysis to automatically calculate flatness parameters.

Types of fringe patterns:

- Straight, parallel fringes: Indicate a wedge (the surface is flat but tilted relative to the reference)

- Circular fringes: Suggest spherical curvature or a “domed” surface

- Irregular fringes: Reveal localized imperfections, ripples, or complex surface errors

Optical Flat Testing

This is a simplified form of interferometry that’s accessible even in modest optical shops. An optical flat is a reference surface with extremely high flatness (typically λ/20 or better, where λ represents the wavelength of light—about 550nm for visible light).

To test a surface, you place the optical flat directly on top of the test piece. A monochromatic light source illuminates the setup from above. The thin air gap between the optical flat and test surface creates interference fringes visible to the naked eye.

This method is excellent for quick quality checks and can reveal flatness to within a fraction of a wavelength. However, it requires direct contact or near-contact with the test surface and provides less detailed information than computerized interferometry.

Profilometer Measurement

Contact and non-contact profilometers measure surface topography by different means:

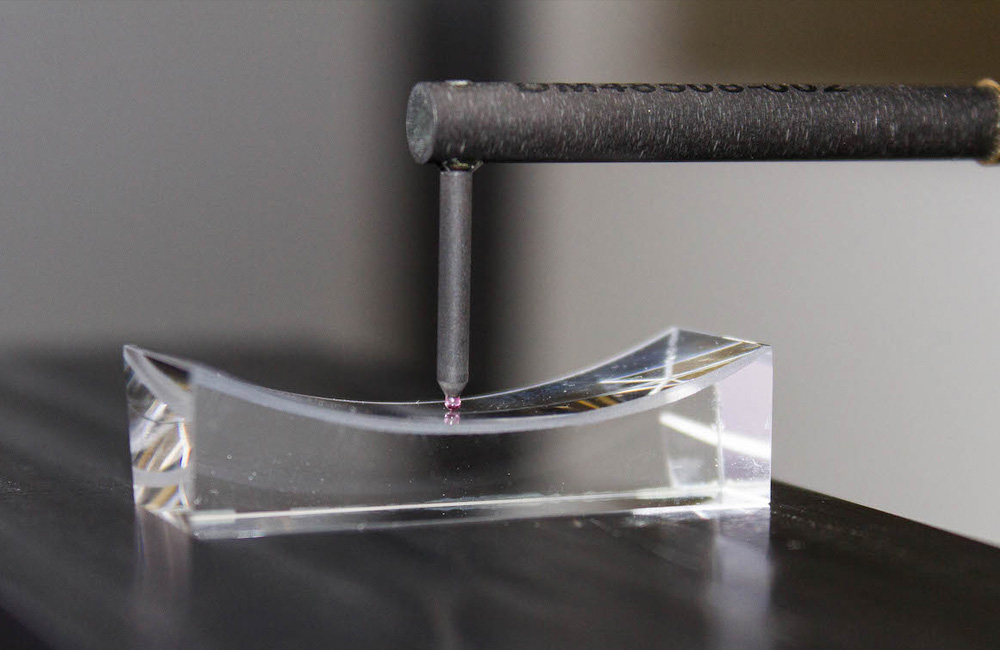

Contact profilometers use a fine stylus that physically traces across the surface, measuring vertical displacement with sub-nanometer resolution. While highly accurate for small areas, they’re slow for large surfaces and risk scratching delicate optics.

Non-contact profilometers use optical sensors, confocal microscopy, or white-light interferometry to scan surfaces without touching them. These instruments build up three-dimensional maps of the surface by taking millions of height measurements across the component.

Profilometers excel at measuring roughness, waviness, and localized features, but for overall flatness of large optical components, interferometry remains superior.

Coordinate Measuring Machines (CMM)

For less demanding applications, CMMs with optical or touch probes can measure flatness by sampling multiple points across a surface. While not as precise as interferometry for optical-grade components, they’re useful for larger substrates or components where extreme flatness isn’t critical.

Conclusion

Measuring glass flatness relies on highly precise optical and mechanical techniques, with interferometry recognized as the gold standard due to its nanometer-level accuracy. By analyzing interference fringes created between a reference flat and the test surface, technicians can visualize and quantify even minute deviations in flatness. Optical flat testing offers a simpler, hands-on version suitable for quick quality checks, while profilometers—both contact and non-contact—provide detailed surface topology and roughness data. For larger or less critical components, coordinate measuring machines (CMMs) offer practical, though less precise, flatness evaluation. Together, these methods enable comprehensive assessment of optical surfaces across varying precision and application requirements.