What Fused Quartz Glass?

Fused quartz glass, also known as fused silica, is an ultra-pure silica-based glass (>99.9% SiO₂) manufactured through high-temperature fusion processes. Unlike borosilicate glass which contains boron trioxide, fused quartz consists almost entirely of silicon dioxide, giving it exceptional thermal, optical, and chemical properties that surpass all other glass types.

With an extremely low thermal expansion coefficient (~0.55 × 10⁻⁶/K) and exceptional purity, fused quartz can withstand extreme temperature fluctuations exceeding 1000°C and harsh chemical environments without degradation. It offers the highest UV transmission of any glass material and maintains structural integrity under conditions where other glasses would fail.

In modern systems demanding uncompromising performance—from high-power laser optics and Deep Ultraviolet (DUV) lithography to advanced thermal processing in semiconductor fabrication—the choice of substrate material is paramount. Our Custom Fused Quartz Glass and its synthetic counterpart, Fused Silica, offer the unique combination of properties essential for these critical technologies.

Custom Fused Quartz Fabrication

At Tihot Optics, we don’t just supply fused quartz plates — we engineer them.

Our fabrication process combines CNC precision, CO₂ laser cutting, flame polishing, and fusion bonding to achieve the exact geometry, flatness, and surface quality you specify.

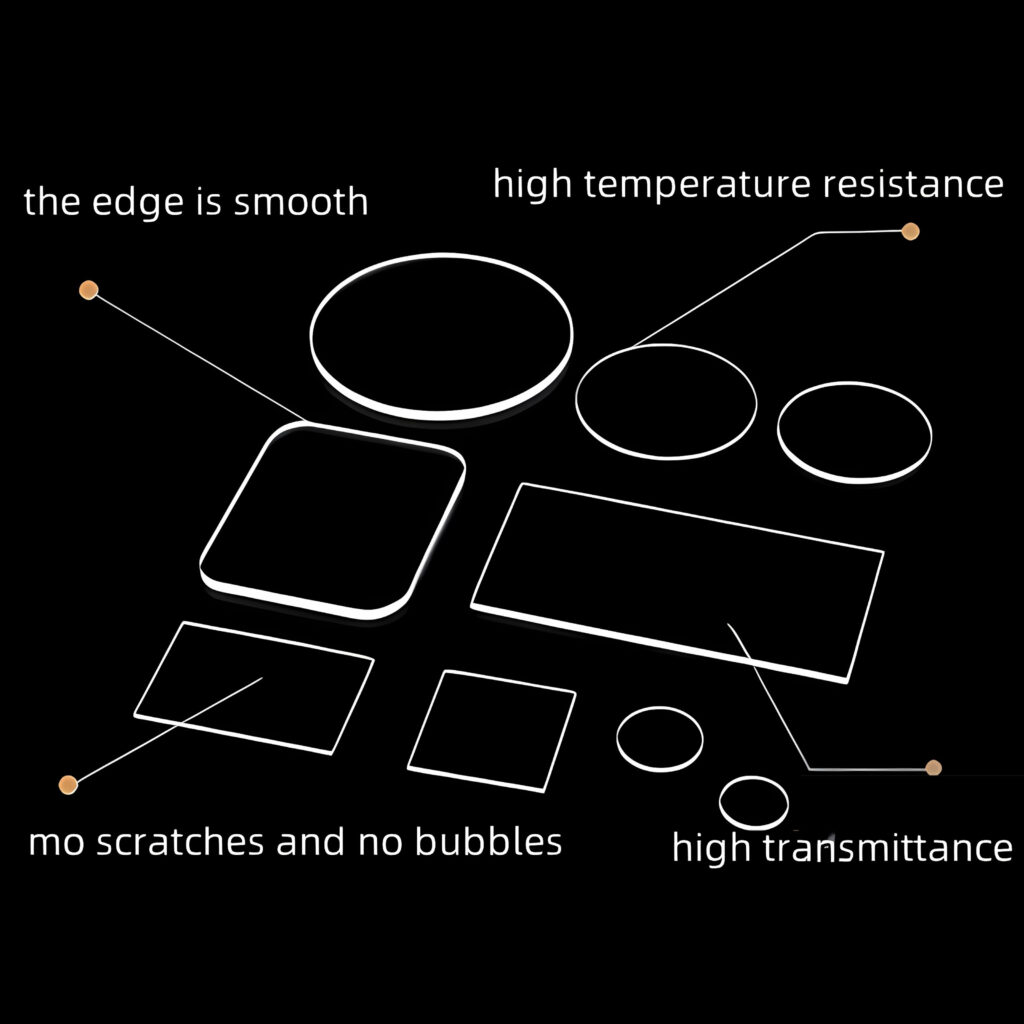

Typical customization options include:

- Thickness: 0.1 mm – 80 mm

- Surface Quality: Scratch-dig 10/5 or better, Ra < 0.5 nm

- Flatness: Up to λ/10 for optical substrates

- Edge Finish: Ground, beveled, or optically polished

- Coatings: AR, ITO, dielectric, or UV-enhanced

- Processes: Thermal annealing, ion polishing, precision drilling, fusion sealing

Every part is metrology-checked for flatness, parallelism, and transmitted-wavefront error to ensure reliability in optical and thermal systems.

Optical and Thermal Grades of Fused Quartz Glass

Selecting the correct quartz grade is the first critical step in fabrication. We process various grades to match the specific operational environment and required wavelength range:

Synthetic Fused Silica (e.g., JGS1 / UV-Grade): Characterized by extremely low metallic impurity and a very low OH content. This material ensures optimal transmission down to the Vacuum Ultraviolet (VUV) spectrum, making it the industry standard for DUV optics, excimer laser components, and high-purity Optical Quartz Parts where internal quality is paramount.

Natural Fused Quartz (e.g., JGS2 / Standard Grade): Derived from natural quartz crystals, this grade offers excellent thermal properties and chemical resistance at a favorable cost point. It is widely used for high-temperature furnace tubes, observation windows, and standard Quartz Substrates where UV performance is secondary to thermal stability.

We manage material selection to guarantee the required purity and homogeneity for every specific Custom Fused Quartz Component.

Applications and Engineering Partnership

Our approach is centered on technical collaboration. We partner with your engineering teams from concept to volume production, providing solutions that integrate seamlessly into your high-performance systems.

- Semiconductor: Furnaces components, process tubes, high-purity Quartz Substrates, and reaction chambers requiring high chemical resistance and thermal integrity.

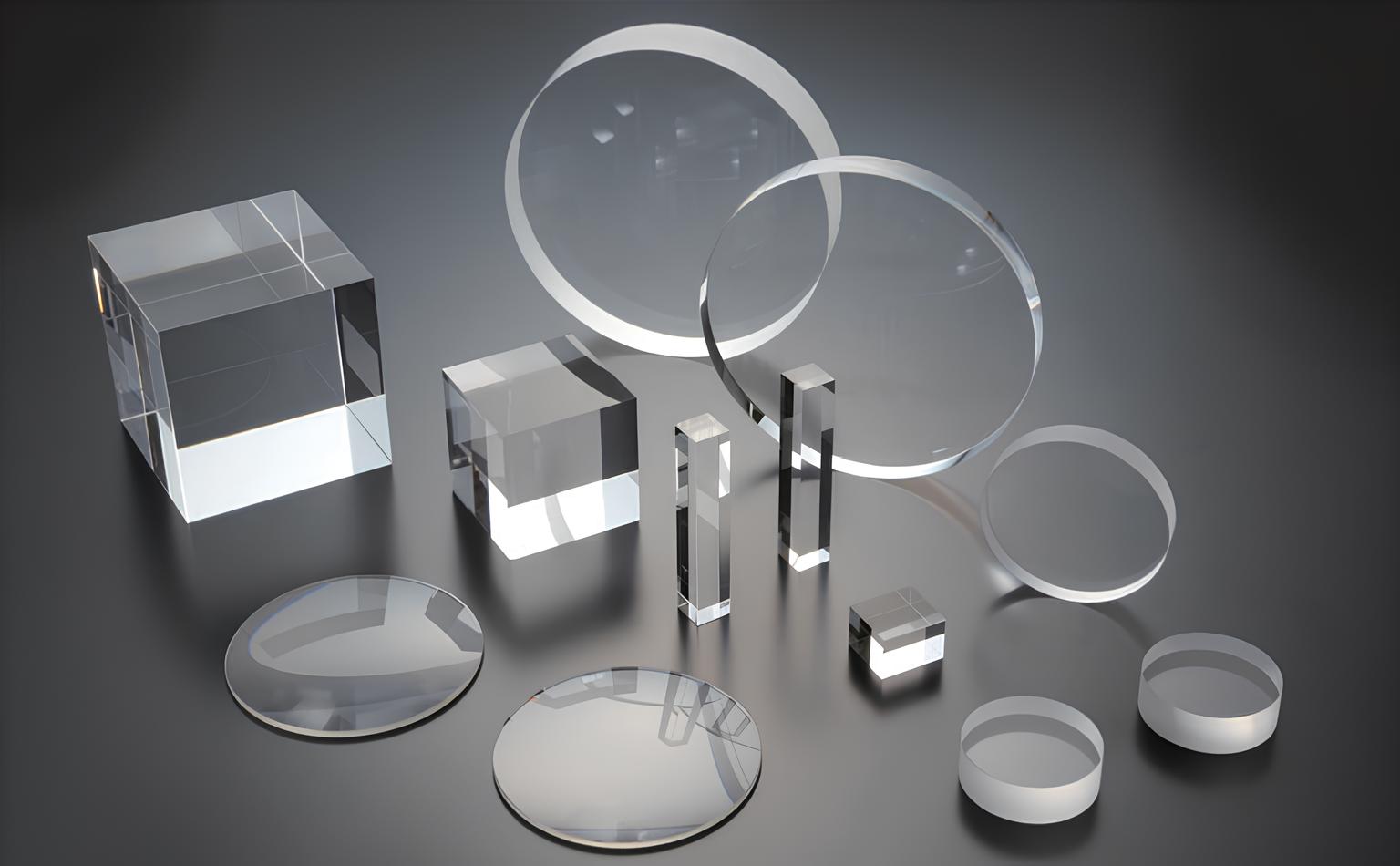

- Optics: Precision windows, lenses, prisms, and test flats for aerospace, deep UV equipment, and analytical instrumentation.

- Industrial/Scientific: Custom flow cells, sight windows, high-temperature labware, and thermal insulators.

Contact us to discuss your project requirements and leverage our expertise in advanced Precision Quartz Fabrication.