ITO Conductive Glass Coated Products

Professional-grade indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) conductive glass substrates designed for advanced research and development applications.

Standard ITO Conductive Glass

High-quality ITO coated glass slides perfect for laboratory research and sensor development.

- Sheet resistance: 4-100 Ω/sq

- Transmission: >85% (550nm)

- Standard sizes: 25×25mm to 300×300mm

- Thickness: 0.7mm, 1.1mm, 2.2mm

- Research grade quality

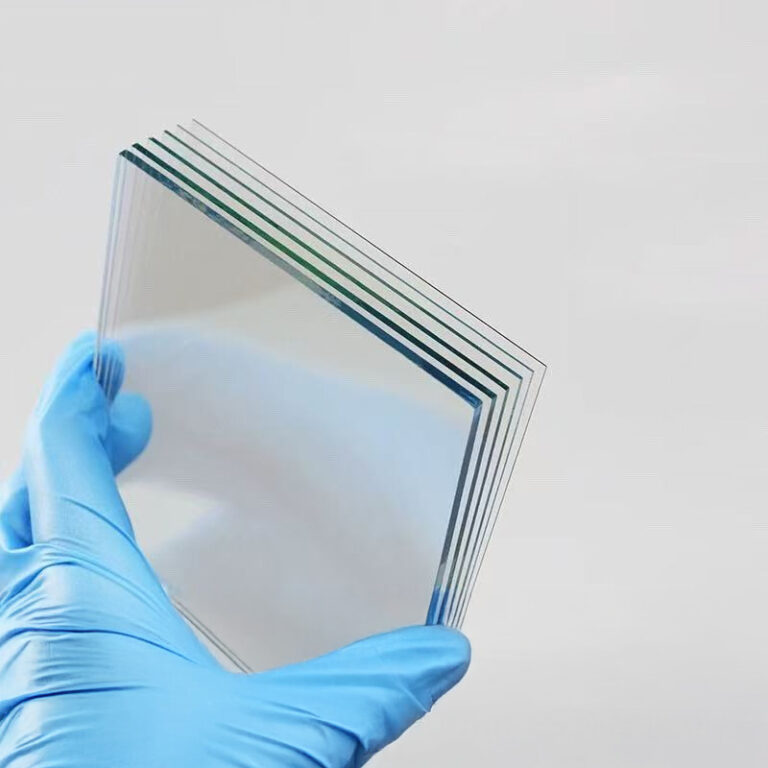

FTO Glass for Solar Cells

Specialized fluorine-doped tin oxide glass optimized for DSSC and perovskite solar cell research.

- Sheet resistance: 7-15 Ω/sq

- Transmission: >80% (550nm)

- High temperature stability

- Chemical resistance

- Solar cell optimized

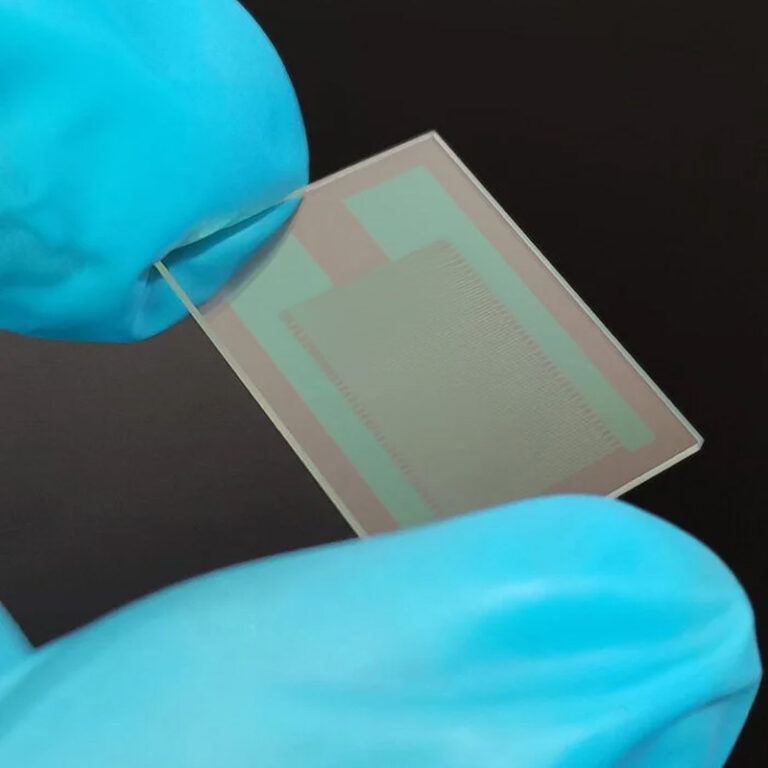

Patterned ITO Glass

Custom-patterned conductive glass with precise electrode designs for specialized applications.

- Custom pattern designs

- Minimum line width: 50μm

- High precision etching

- Prototype to production

- Fast turnaround time

Research Grade Specifications

Detailed technical specifications for our conductive glass products, meeting international research standards.

| Parameter | ITO Glass | FTO Glass | Testing Method |

|---|---|---|---|

| Sheet Resistance | 4-100 Ω/sq | 7-15 Ω/sq | Four-point probe |

| Transmittance (550nm) | >85% | >80% | UV-Vis Spectrophotometer |

| Coating Thickness | 150-300 nm | 400-600 nm | Profilometer |

| Surface Roughness (Ra) | <15 nm | <25 nm | AFM |

| Work Function | 4.8 eV | 4.4 eV | UPS |

| Max Processing Temp | 300°C | 500°C | – |

Product Line & Quick Specs

Complete range of sapphire glass products for optical, vacuum, and semiconductor applications

What Is ITO/FTO Coated Glass?

ITO stands for Indium Tin Oxide, while FTO refers to Fluorine-doped Tin Oxide. Both are transparent conductive oxide (TCO) coatings deposited on glass substrates, combining high optical transparency with electrical conductivity.

Why It Matters for Research and Industry

Transparent conductive glass is essential in applications where light transmission and electrical performance must coexist. For example, laboratories and R&D centers use ITO/FTO glass as electrodes in solar cell prototypes, sensors, displays, and optoelectronic devices. In industry, it enables technologies like touch panels, OLED displays, smart windows, and thin-film photovoltaics. By providing a stable, customizable platform, ITO and FTO conductive glass serve as indispensable materials bridging optics and electronics.

Reliable ITO/FTO Glass Manufacturer

we provide tailor-made conductive glass solutions for universities, research institutes, and enterprise R&D centers.

ITO conductive glass from the laboratory of Tsinghua University

FTO film glass in the laboratory of Sun Yat-sen University

Photoelectric glass in a certain laboratory of the California Institute of Technology

Photoelectric glass in a laboratory of the Technical University of Munich

ITO conductive film glass from New York University laboratory

Photoelectric glass in a certain laboratory of the University of Cambridge

Why Choose us ITO/FTO Coated glass

Our ITO conductive Coated glass provides high optical transmittance and low sheet resistance, making it the preferred choice for touch panels, displays, sensors, and laboratory research. FTO conductive glass, with its excellent chemical stability and heat resistance up to 500 °C, is widely used in solar cells, DSSC, and photoelectrochemical devices.

At TIHOTOPTICS, we support both standard formats and custom processing—including precision cutting, polishing, etching, and functional coatings—so every solution matches your specific project requirements. More than a supplier, we are your trusted partner in developing innovative conductive glass solutions.

Laboratory & R&D Applications

Our conductive glass substrates are widely used across various research fields and industrial applications.

Solar Cell Research

DSSC, perovskite, and organic photovoltaic cell development

Sensor Development

Electrochemical sensors, biosensors, and gas sensors

Display Technology

LCD research, OLED development, and flexible displays

Electrochromic Devices

Smart windows and variable transmission devices

Thin Film Research

Conductive coatings and transparent electrode studies

Microelectronics

Transparent circuits and flexible electronics

Quality Assurance

ISO 9001:2015 certified manufacturing facility with in-house metrology lab. All products undergo rigorous quality control including dimensional inspection, surface analysis, and optical performance testing.

FAQs about ITO/FTO Coated Glass

Operating Principle of Conductive Glass (ITO/FTO)

Operating Principle: Conductive glass is usually produced by coating conductive materials such as indium tin oxide (ITO) or fluorine-doped tin oxide (FTO) on the surface of the glass. These conductive films can form a uniform conductive layer and create conductive electrodes on the glass surface, which are used in solar panels, touch screens, and other fields.

Applications: Conductive glass is commonly used in solar panels, touch screens, and liquid crystal displays, where it forms a transparent conductive layer to achieve touch operation or photoelectric conversion.

Features: Conductive glass has high light transmittance, excellent conductivity, and chemical stability. It also enables flat and transparent touch screens and is widely used in various electronic products.

Different Uses or Materials of Conductive Glass (ITO/FTO)

Conductive glass is usually used in optics, electronics, or solar energy as a transparent conductive material, featuring high transparency and excellent conductivity.

ITO (indium tin oxide) and FTO (fluorine-doped tin oxide) are common conductive glass materials, which can be used in the production of solar cells, touch screens, and liquid crystal displays.

The surface of conductive glass is usually specially treated to improve conductivity and durability, while also providing excellent optical performance, making it applicable in a variety of optical and electronic devices.

How to Choose the Right Conductive Glass (ITO/FTO)

Material: ITO (indium tin oxide) and FTO (fluorine-doped tin oxide) are two common conductive glass materials with excellent conductivity and light transmittance, widely used in optoelectronic devices, solar cells, and LCDs.

Characteristics: ITO has higher conductivity and light transmittance, commonly used in flat panel displays and solar cells. FTO has lower conductivity but higher corrosion resistance, often used in photoelectrochemical devices and touch screens.

Selection: Choose the appropriate conductive glass material according to application needs and material properties, considering conductivity, optical performance, and corrosion resistance.

When to Maintain Conductive Glass (ITO/FTO)

Regularly check the surface of conductive glass for scratches, oxidation, or other damage. If found, replace or repair in time.

Use mild cleaners and soft cloths to clean the surface of conductive glass, and avoid using hard or rough cleaning tools.

Avoid exposing conductive glass to humid or acidic environments for long periods in order to extend its service life and maintain its conductivity.