Glass Substrates Supplier

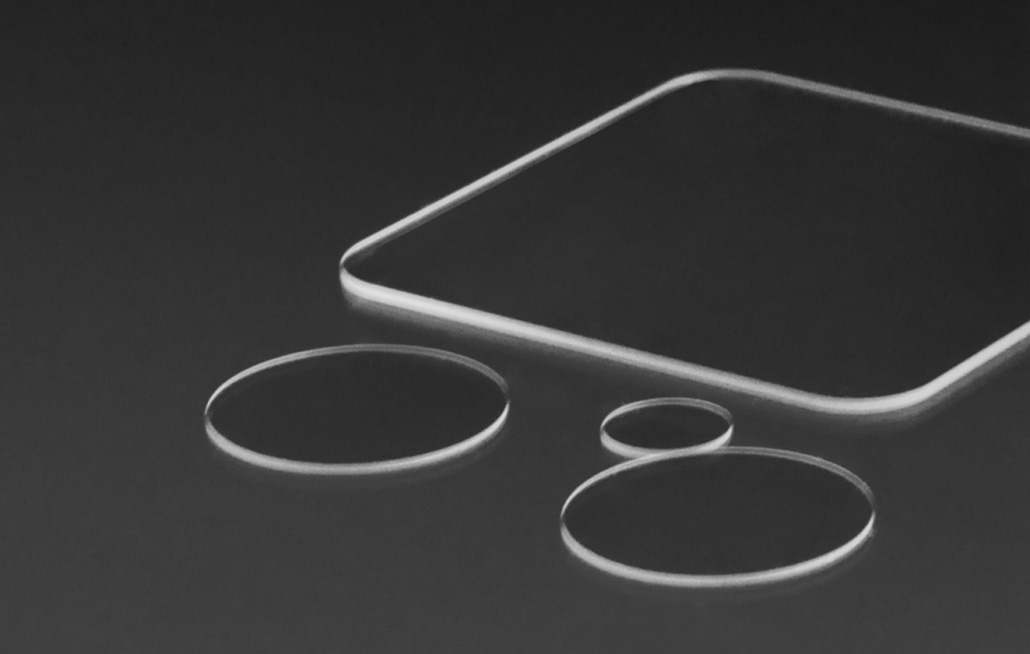

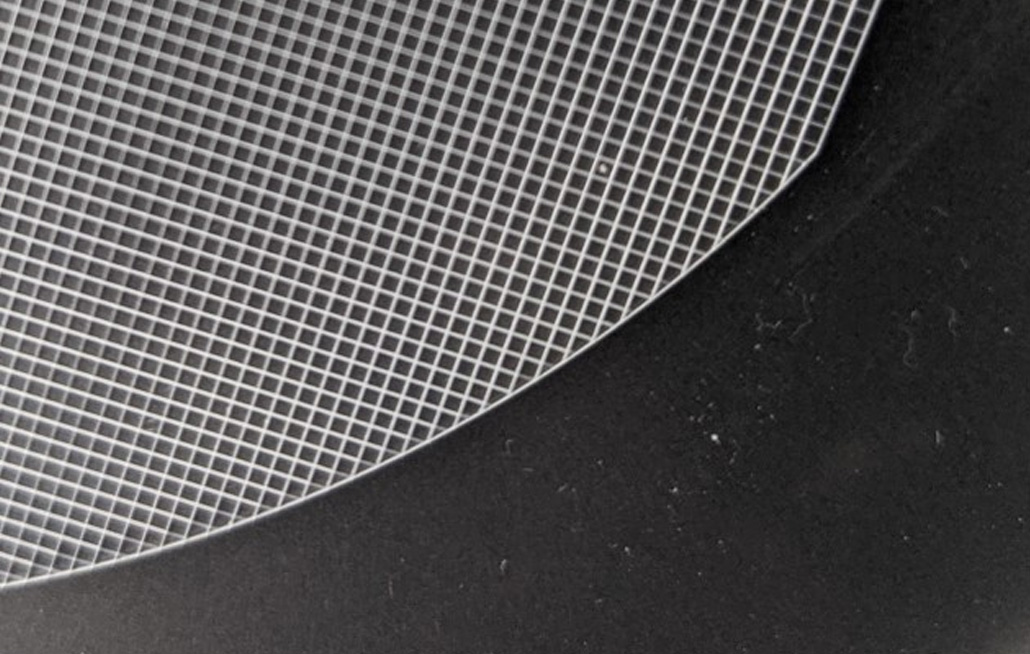

Our glass substrates are engineered for high-performance applications across photonics, semiconductors, microelectronics, and biomedical research. Whether you’re working with optical glass substrates, thin glass substrates, or fused silica substrates, we provide consistently reliable material with excellent flatness, purity, and transmission characteristics. As a trusted glass substrate supplier, we offer standard and custom formats in quartz substrate glass, borosilicate glass substrates, all processed under strict quality control to meet the demands of laser systems, optical coatings, and MEMS fabrication.

No products found

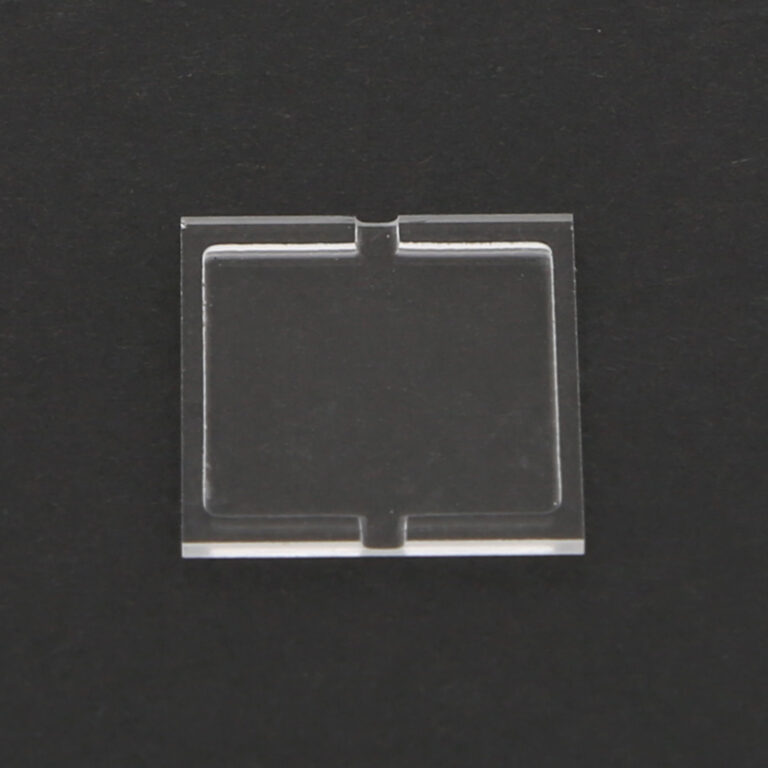

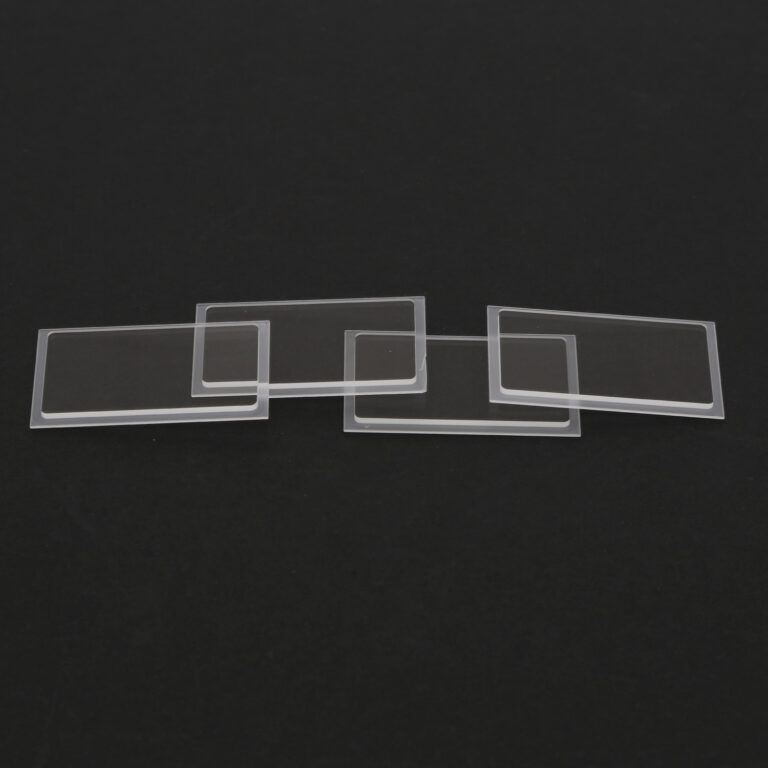

Custom Substrate Glass Manufacturing

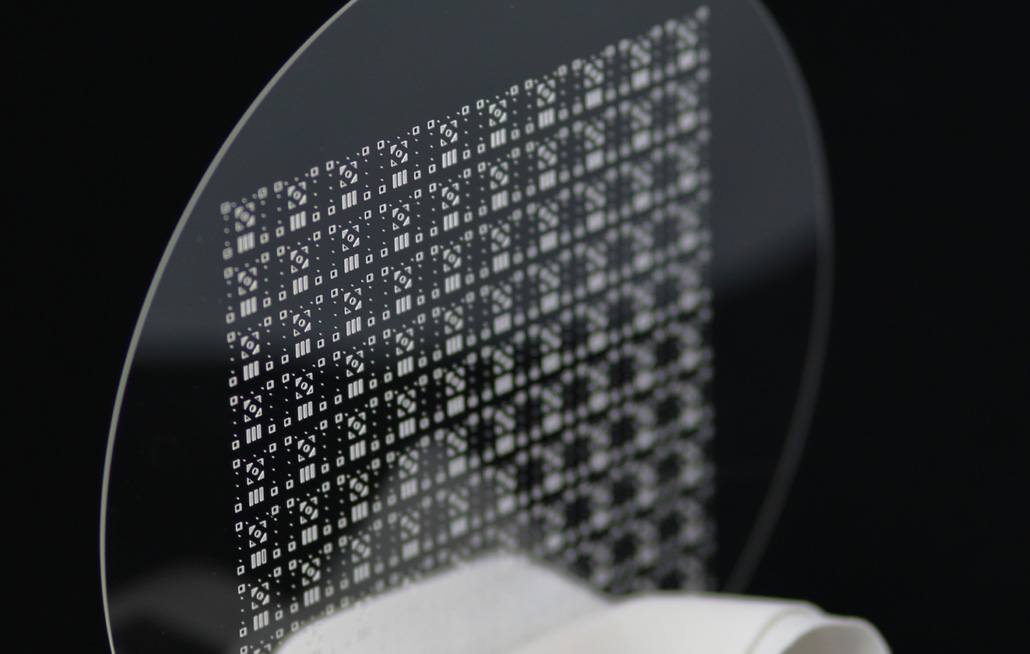

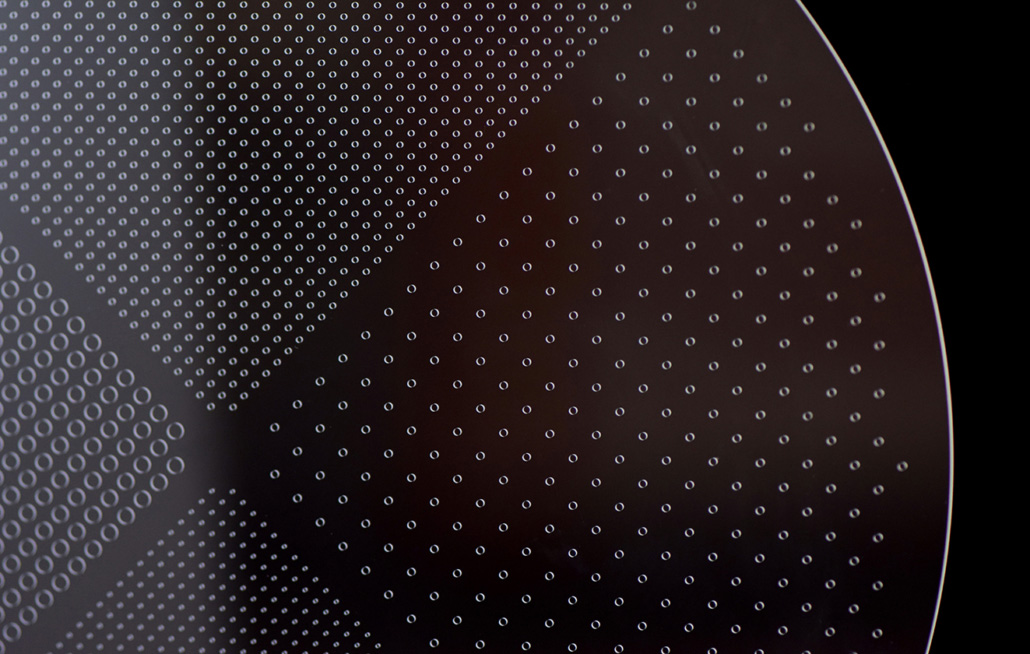

At our facility, we specialize in custom substrate glass manufacturing, delivering precision glass substrates tailored to your technical requirements. We offer a wide variety of finishes, including ITO-coated glass substrates, AR coated glass substrates, and custom cut glass substrates for prototyping or volume production. Our substrates are ideal for use in glass wafer substrates, microscope glass substrates, and substrate glass for laser devices, MEMS, photonics, and semiconductor processing. With advanced capabilities in cutting, polishing, coating, and CNC machining, we help innovators push the limits of micro-scale performance. Get in touch with a trusted glass substrate manufacturer to request your custom quote today.

Materials We Offer for MEMS Glass Substrates

Our Glass Processing Capabilities for MEMS and Sensors

Wafer thinning down to 50 µm

Precision cutting & dicing (standard wafer sizes: 100 mm / 150 mm / 200 mm / 300 mm)

Micro-hole drilling, via holes, and cavity creation

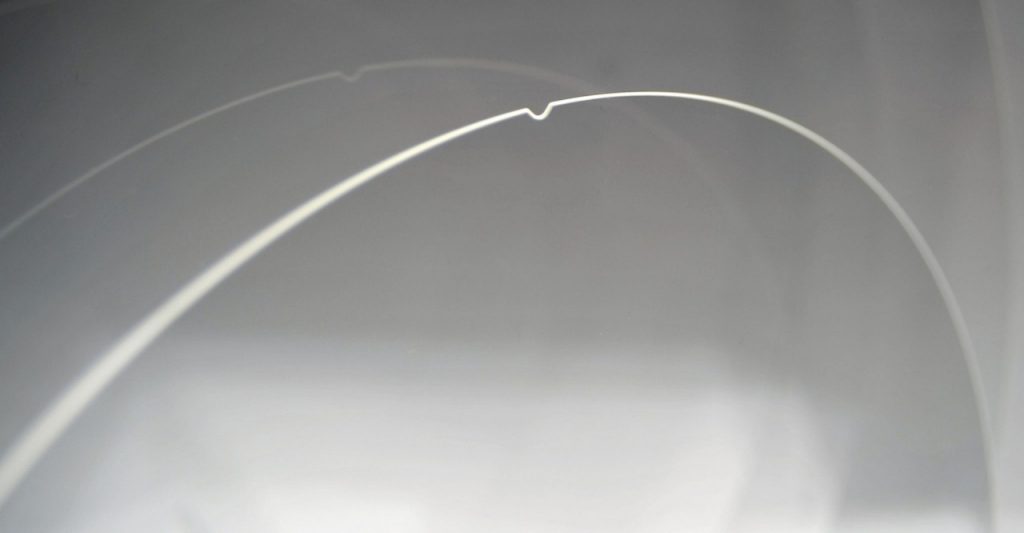

Edge grinding and chamfering to minimize chipping

Surface polishing (Ra < 1 nm possible)

Glass-to-silicon bonding prep (cleaning, planarity control)