产品: 4-Inch Borosilicate Glass Wafers

Featured products

4-Inch Borosilicate Glass Wafers

Basic Dimension Outline:

-

Diameter: 100mm ± 0.2mm

-

Standard Thickness: ~500μm (customizable)

-

Edge Finish: Ground and Beveled

-

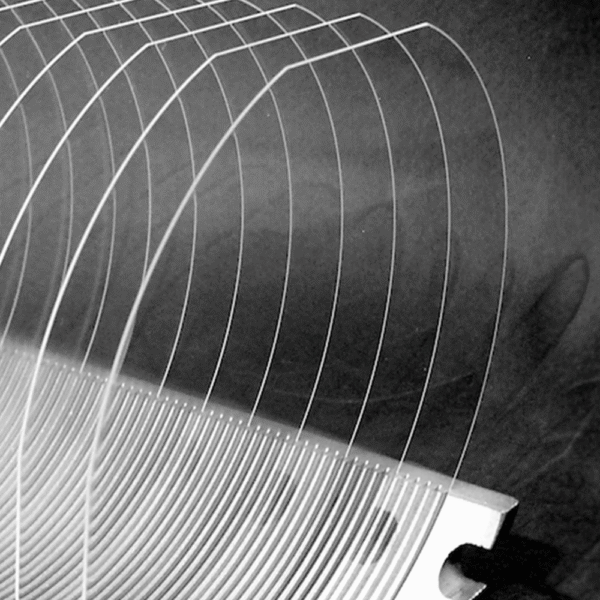

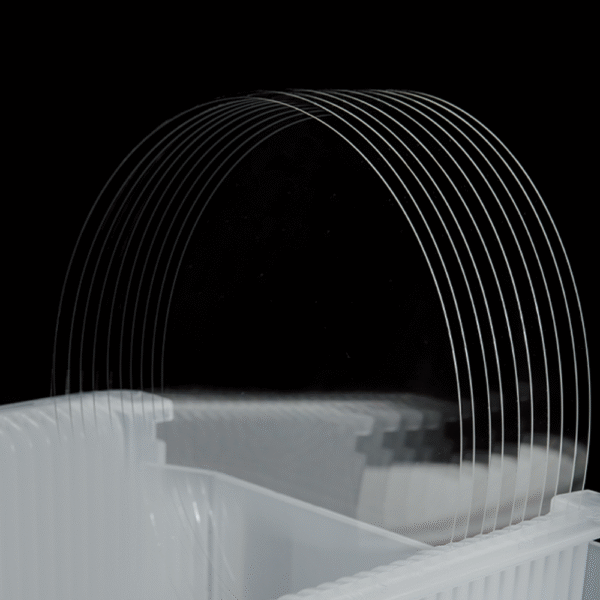

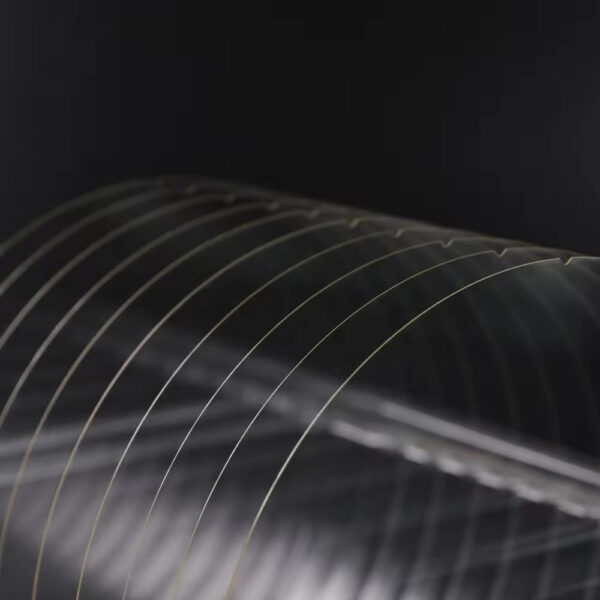

Surface: Double Side Polished

-

TTV: ≤5μm, BOW/WARP: ≤25μm

-

Orientation: SEMI Standard flat available or fully round per request

(Custom dimensions and shapes available upon consultation.)

Key Features of 100mm BF 33 Wafer Glass

- Outstanding Thermal Stability: Our glass wafers exhibit minimal expansion and superior performance under high-temperature processing conditions.

- Superior Chemical Durability: The wafer glass resists water, acids, alkalis, and organic solvents, maintaining integrity in aggressive chemical environments.

- Exceptional Mechanical Strength: Engineered for toughness and minimal warping, ideal for fragile semiconductor and MEMS processes.

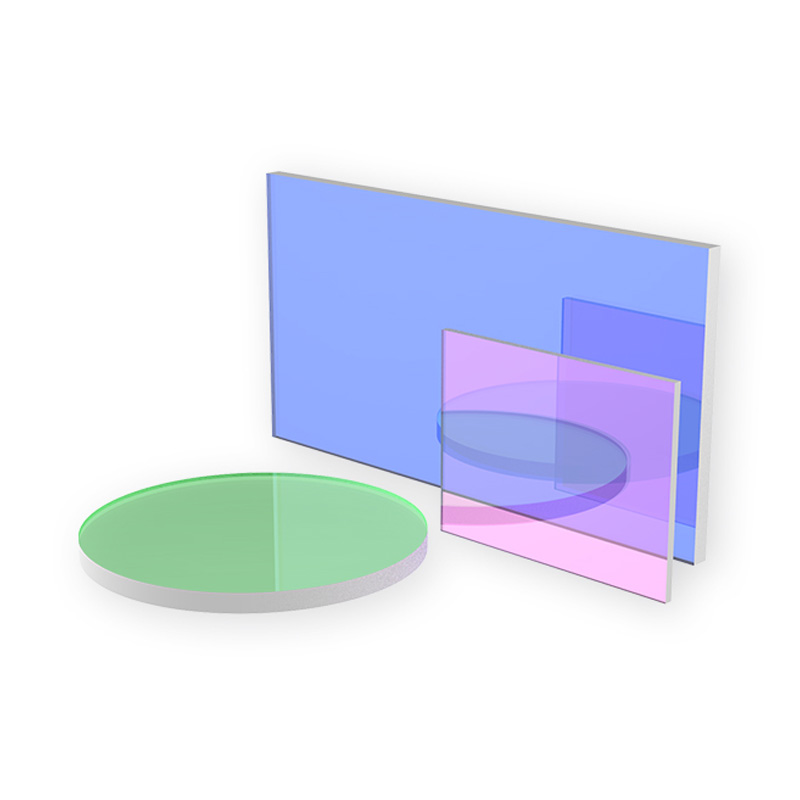

- High Optical Clarity: Ultra-smooth, double-side polished surfaces provide maximum transparency in the visible and near-IR spectr

- Consistent Quality Assurance: Each glass wafer undergoes rigorous inspection to ensure industry-compliant performance and dimensional stability.

- Customization Ready: Available in custom thicknesses, edge finishes, coatings, and special dimensions to meet unique application needs.

Applications of 4” Glass Wafer

The unique combination of thermal, optical, and mechanical properties makes our glass wafers suitable for a wide range of cutting-edge applications, including:

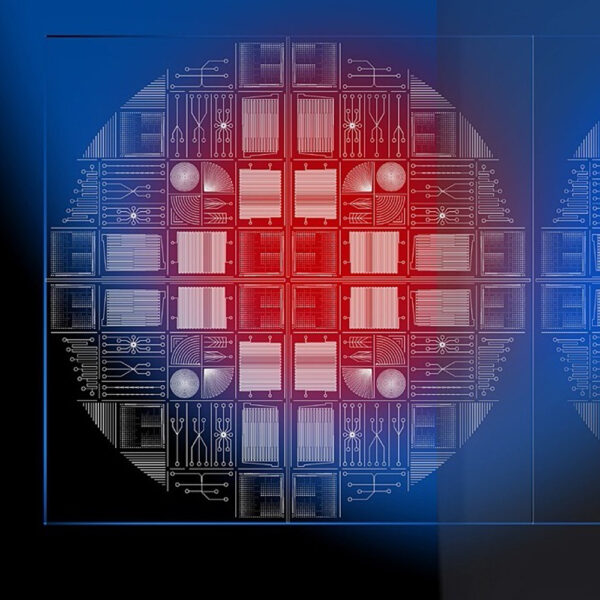

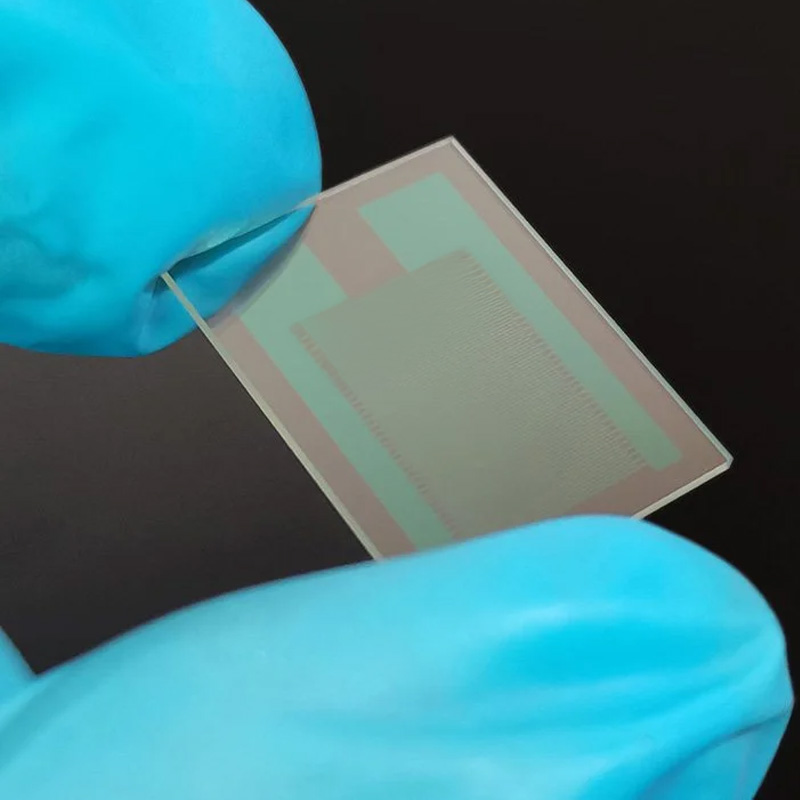

- Semiconductor Processing: Mask substrates, carrier wafers, and thin-film deposition.

- MEMS Devices: Microfluidic chips, sensors, and actuators.

- Optoelectronics and Photonics: Laser components, optical substrates, and projection systems.

- Biotechnology and Medical Devices: Biochips, diagnostic instruments, and lab-on-a-chip devices.

- Research and Development: University and industrial research projects involving microfabrication and optical testing.

- Sensor Technology: Gas sensors, biosensors, and environmental monitoring equipment.

Our wafers offer the dimensional precision and reliability needed for critical manufacturing and research environments.

Customization Options for BF 33 Wafers

Recognizing that standard specifications may not always fit project needs, we offer extensive customization services for our Borofloat 33 glass wafers, including:

- Custom Thickness: Ranging from ultra-thin 200μm to thicker substrates over 1mm.

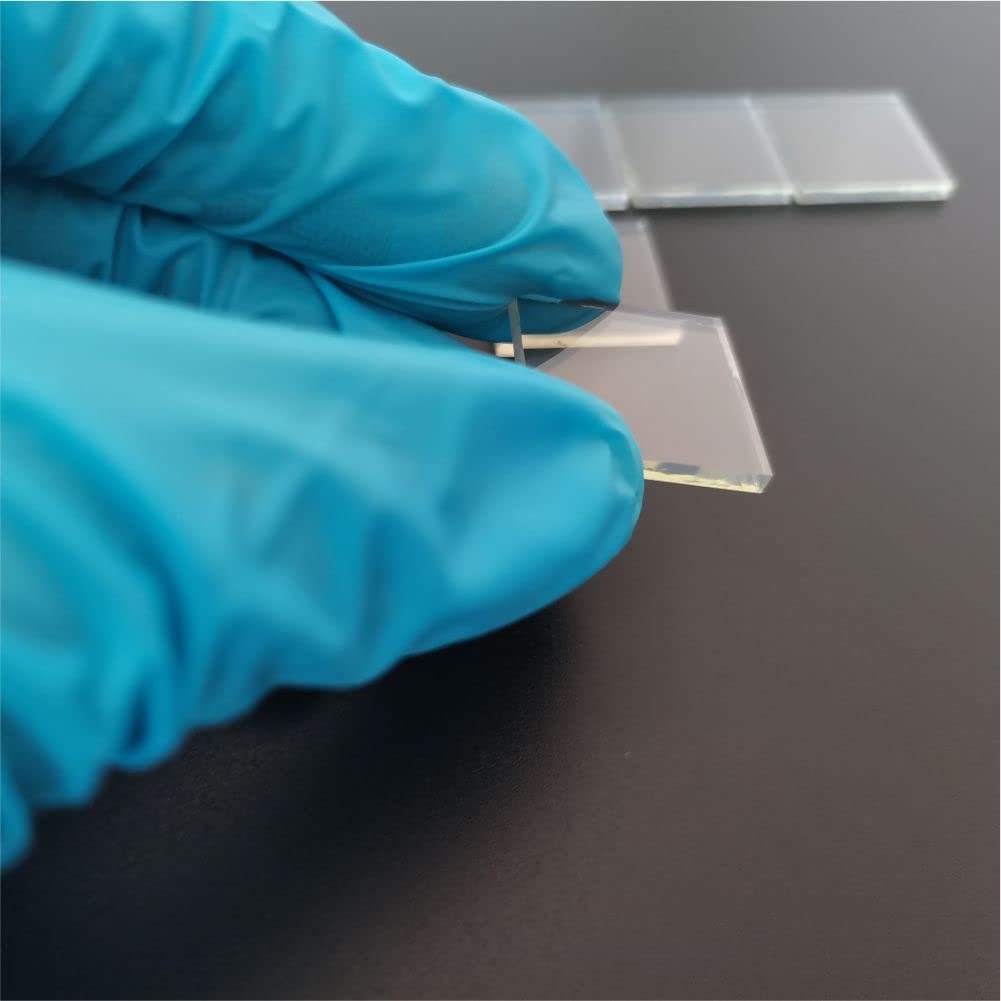

- Special Diameters: From smaller 2″ wafers up to 6″, 8″, and larger, with precision diameter control.

- Edge Treatments: Customized beveling, rounding, or special flat/nick patterns.

- Coatings: Anti-reflective (AR), conductive (ITO), hydrophobic/hydrophilic coatings, and more.

- Laser Dicing and Shaping: Custom diced chips, squares, rectangles, or specialized geometries.

- Surface Modifications: Single-side polishing, structured surfaces, or etched alignment marks.

Each custom order is handled with precision processes to maintain the same high-quality standards as our standard wafer glass products.

Why Choose Our Wafer Glass?

We specialize in delivering top-grade wafer glass materials tailored to critical industries. As an experienced borosilicate Glass Supplier, our products provide:

- Reliable Supply Chains: Global fulfillment, with strong delivery logistics across North America, Europe, and Asia-Pacific regions.

- Advanced Fabrication Capability: Precision cutting, polishing, and dicing for customized requirements.

- Competitive Pricing: Especially for bulk orders with flexible MOQ (Minimum Order Quantities).

- Expert Technical Support: Our engineers assist in choosing the perfect wafer solution for your specific process needs.

Our deep experience in manufacturing and supplying wafer glass ensures our clients receive wafers optimized for success in advanced technological applications.

Quantity Discounts for Bulk Orders

We offer highly competitive pricing for bulk purchases of wafer glass products.

For orders of 100 wafers or more, customers can benefit from customized quotations and priority production scheduling.

Contact us today to discuss your volume requirements and enjoy premium wafers at reduced costs.

Contact Us Today

Are you ready to elevate your projects with premium bf 33 glass wafers?

Reach out to our experienced sales team for pricing, sample requests, and custom fabrication services.

We guarantee high-quality products, reliable delivery, and world-class customer support to meet the highest standards of semiconductor, MEMS, and optical industries.

Partner with a leading wafer Glass Supplier you can trust — connect with us today for your wafer glass needs.

| Spec | 4″ | 6″ | 8″ | 10″ | 12” |

| Diameter | 100mm | 150mm | 200mm | 250mm | 300mm |

| Thickness | 0.10mm | 0.30mm | 0.40mm | 0.50mm | 0.50mm |

| Primary Flat | 32.5mm | 47.5mm/ 57.5mm/ Notch | Notch | Notch | Notch |

| LTV (5mmx5mm) | < 0.5um | < 0.5um | < 0.5um | < 0.5um | < 0.5um |

| TTV | < 2um | < 3um | <3um | <10um | <10um |

| Bow | ±20um | ±30um | ±40um | ±40um | ±40um |

| Warp | ≤ 30um | ≤ 40um | ≤ 70um | ≤ 80um | ≤ 80um |

| Edge Rounding | Compliant with SEMI M1.2 Standard/refer to IEC62276 | ||||

| Surface Type | Single Side Polished / Double Sides Polished | ||||

| Polished side Ra | Ra≤1nm | ||||

| Back Side Criteria | Ra 0.2-0.7um or Customized | ||||

Leave Your Message