产品: Alkali-Free Glass Wafers

Featured products

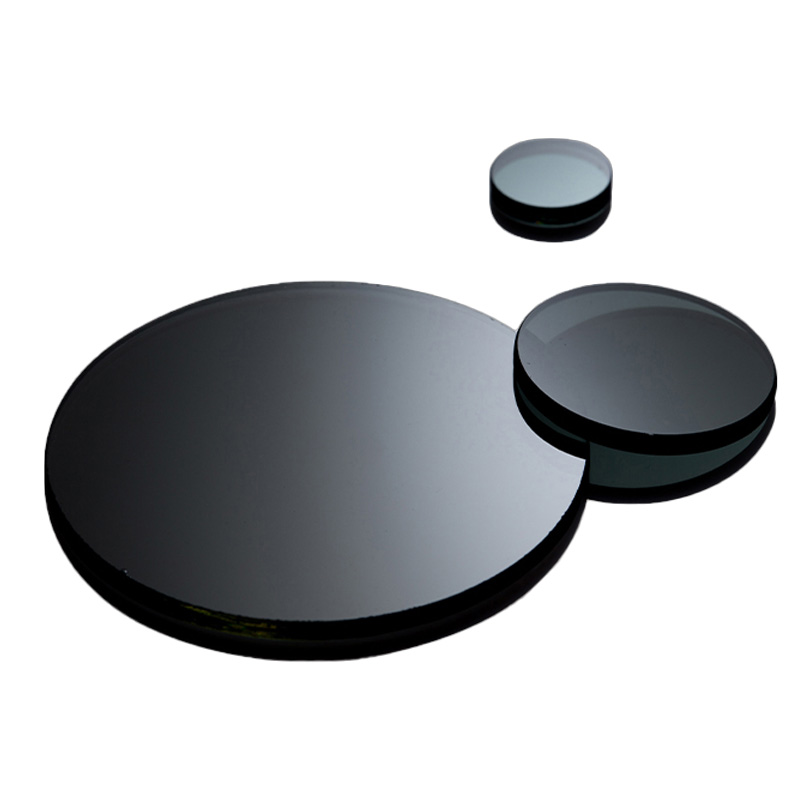

Alkali-Free Glass Wafers

Key Technical Specifications – Alkali-Free Glass

| Property | Value | Unit / Notes |

|---|---|---|

| Type | Alkali-free display glass | Free of Na⁺, K⁺, As, and heavy metals |

| Density | ~2.38 | g/cm³ |

| Thermal Expansion Coefficient | ~3.2 × 10⁻⁶ | /K (20°C–300°C), silicon-compatible |

| Young’s Modulus | ~73 | GPa |

| Refractive Index | ~1.51 | @ λ = 587.6 nm |

| Surface Roughness | < 0.5 | nm (as-drawn), can be polished to Ra ≤ 0.01 µm |

| Transmission | >90% | 400–700 nm visible range |

| Softening Point | ~820 | °C |

| Annealing Point | ~639 | °C |

| Lead/Arsenic Content | None | RoHS & REACH compliant |

Alkali-free glass is a specialized, high-purity glass substrate engineered without alkali ions such as sodium (Na⁺) or potassium (K⁺). This composition prevents ionic migration, ensuring dimensional stability and excellent chemical durability in semiconductor and display manufacturing processes.

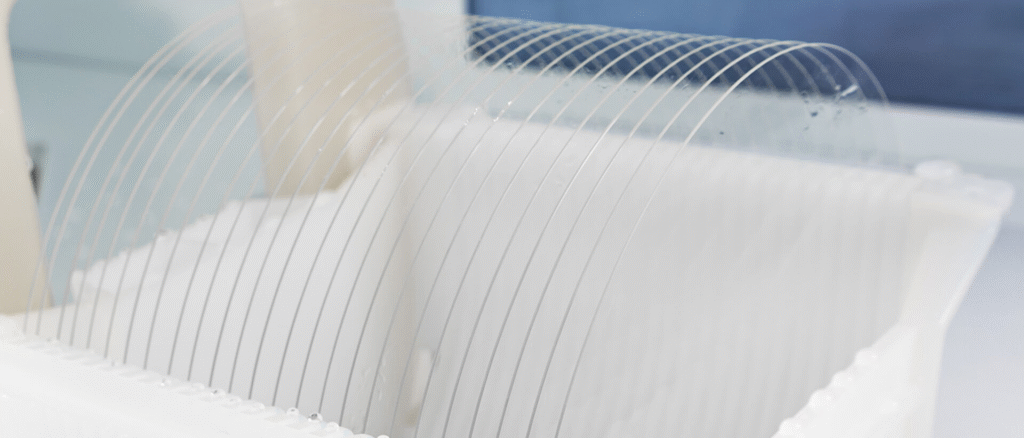

Manufactured using advanced fusion draw or float methods, alkali-free glass offers superior surface flatness, low thermal expansion, and high optical transmission—making it ideal for TFT-LCD, OLED, photolithography, and thin-film device fabrication.

Why Choose Alkali-Free Glass Wafers for Precision Applications?

- Alkali-Free Composition: Free of Na⁺ and K⁺ ions—prevents contamination in IC and OLED processes.

- Thermal Compatibility: Coefficient of thermal expansion (CTE ≈ 3.2 × 10⁻⁶ /K) matched with silicon wafers and semiconductor layers.

- High Optical Clarity: >90% visible light transmission—ideal for optical imaging and photomask substrates.

- Ultra-Smooth Surface: Surface roughness <0.5 nm ensures uniform thin-film coating and bonding performance.

- Environmentally Friendly: No lead, arsenic, or antimony—safe for cleanroom and eco-friendly production lines.

Your Trusted Alkali-Free Glass Supplier and Custom Processor – TiHot

TiHot is a professional manufacturer and processor specializing in custom alkali-free glass wafers and substrates. We serve display, photonic, and semiconductor industries with precision-engineered glass components tailored to OEM and laboratory requirements.

Our capabilities include:

- Global supply with RoHS / MSDS documentation

- OEM & R&D-scale alkali-free wafer fabrication

- Drawing-based customization (DXF / STEP / PDF compatible)

- Ultra-thin and large-format wafer processing

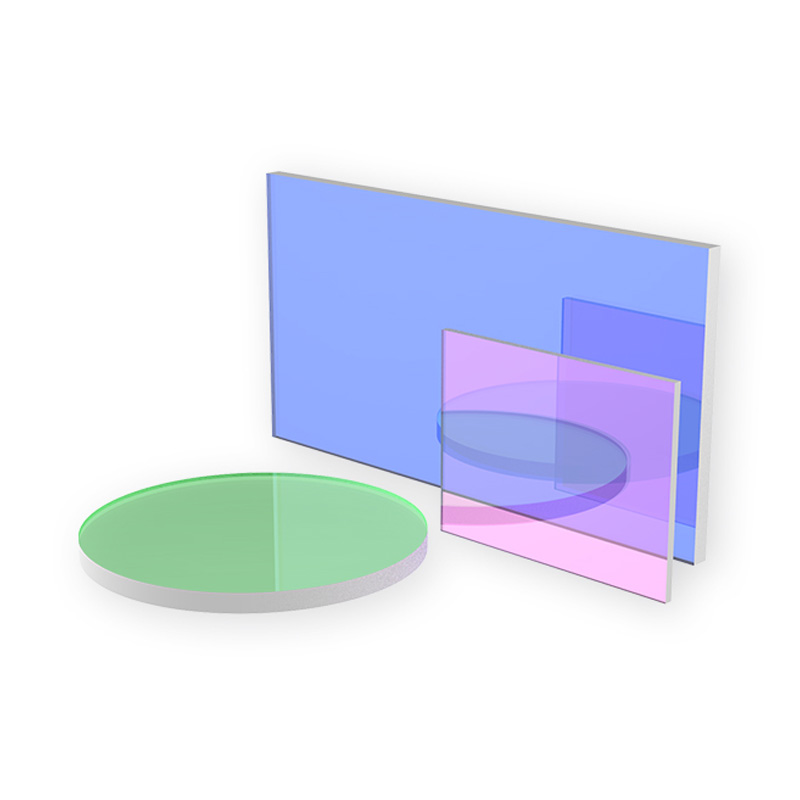

Alkali-Free Glass Processing Capabilities

TiHot provides complete CNC and surface finishing solutions for alkali-free glass substrates, including ultra-thin wafers used in high-end manufacturing:

| Process Type | Specification & Capability |

|---|---|

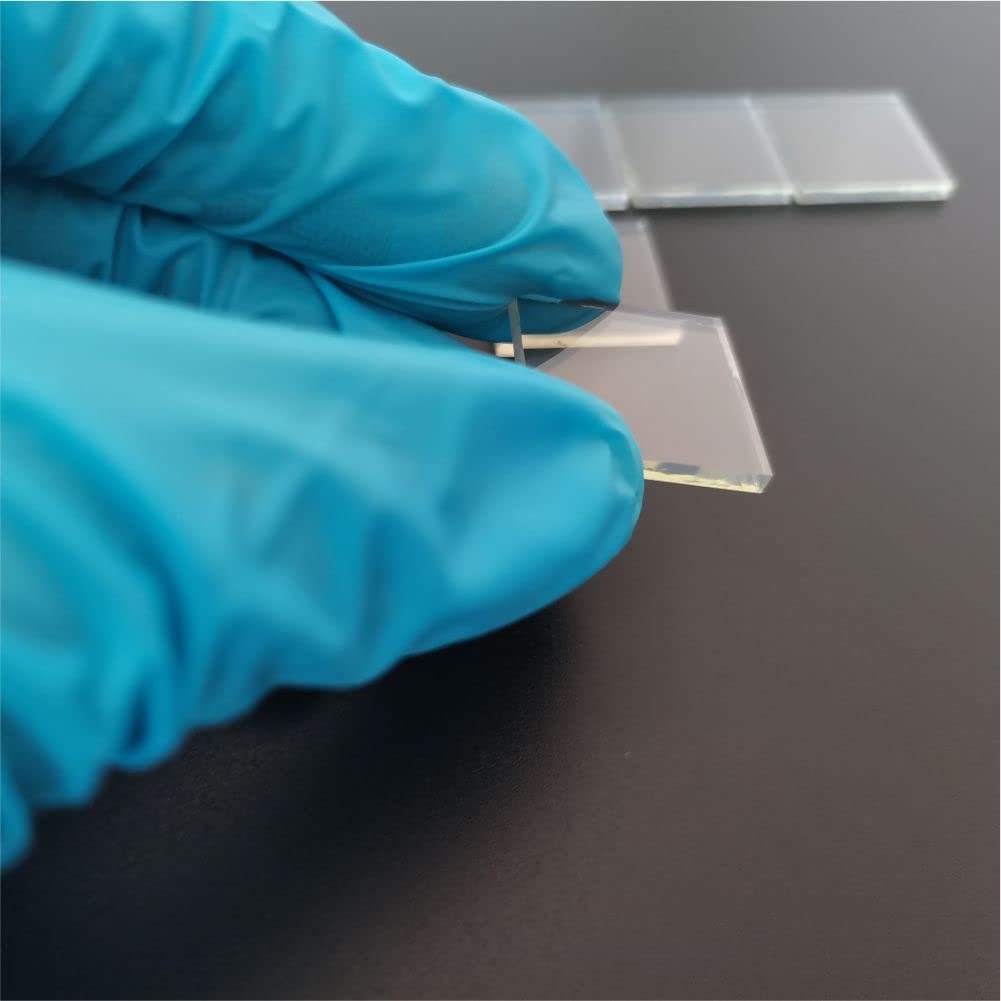

| Precision Cutting | ±0.01 mm tolerance, any shape (round/square/irregular) |

| CNC Slotting & Dicing | Suitable for photomask, OLED, or MEMS applications |

| Edge Finishing | C-edge, D-edge, beveled, or chamfered for safety |

| Micro Drilling | Hole diameter ≥ 0.1 mm |

| Surface Polishing | Optical polish & lapping (Ra ≤ 0.01 µm) |

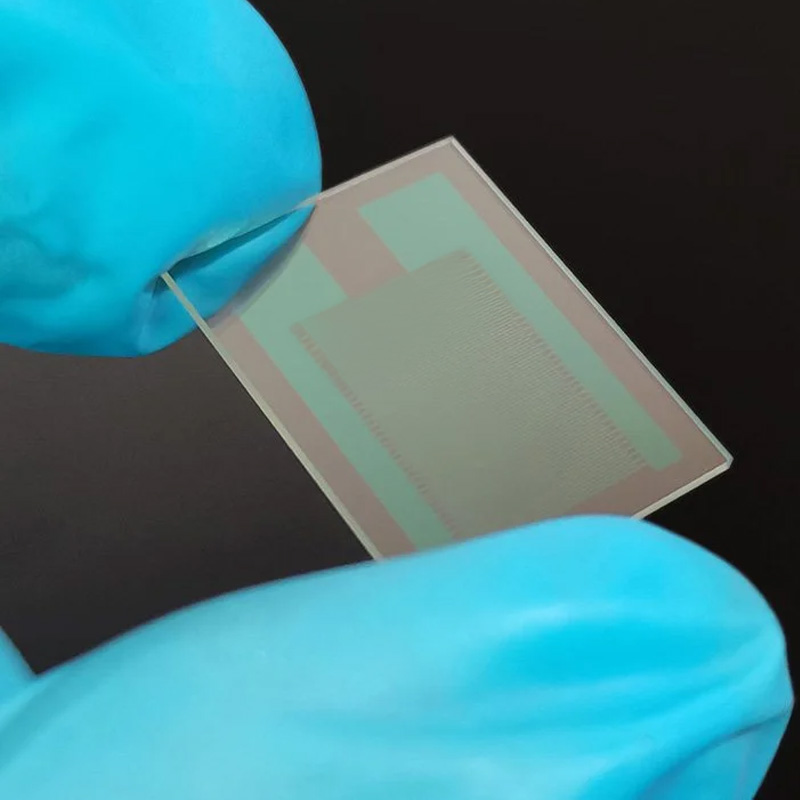

| Coating Services | ITO, FTO, dielectric, AR/AF coatings available |

| Thermal Processing | Annealing, thermal strengthening, or lamination |

All substrates are ISO-inspected and delivered in cleanroom-grade packaging.

Industries and Applications

Display and Optoelectronics

- TFT-LCD and OLED backplane substrates

- Touch panel carriers and color filter glass

- Photomask blanks for flat panel manufacturing

Semiconductor and Microfabrication

- Photolithography and vacuum deposition carriers

- Wafer-level packaging and thin-film electronics

- Insulating layers for IC and MEMS devices

Biomedical and Diagnostics

- Transparent microfluidic chips

- Optical imaging and biosensor substrates

- Clean, chemically stable coverslips

Laser and Precision Optics

- Calibration and inspection windows

- Laser shielding and filter plates

- Optical alignment and metrology wafers

Supporting Research and Innovation

TiHot supports research institutions, display fabs, and R&D laboratories worldwide with flexible customization and small-batch supply. Whether you need:

- Ultra-thin alkali-free substrates for flexible electronics

- ITO- or AR-coated wafers for prototyping

- Cleanroom-packaged samples for optical testing

People Also Ask About Alkali-Free Glass

1. What is the main advantage of alkali-free glass over standard glass?

It eliminates ionic contamination (Na⁺, K⁺) that can degrade thin-film device performance, making it ideal for semiconductors and displays.

2. What are the available thicknesses for alkali-free glass wafers?

Common thicknesses range from 0.2 mm to 1.1 mm, with ultra-thin options polished to custom specifications.

3. Can alkali-free glass be used for photolithography and OLED processes?

Yes, its low ion content and high thermal stability make it compatible with photoresist coating, UV exposure, and high-vacuum processes.

4. Are coatings such as ITO or dielectric layers supported?

Absolutely. TiHot provides ITO, FTO, AR, and dielectric coatings with precise uniformity control for electronic and optical applications.

5. Can alkali-free glass be customized into round or square formats?

Yes. Available in round (2″, 4″, 6″) or square (up to 300 mm) formats, with full CNC customization.

6. What is the surface roughness of alkali-free glass?

Our precision-polished wafers achieve Ra ≤ 0.01 µm, ideal for microfabrication and bonding.

7. Is edge polishing available?

Yes, we offer beveled, C-edge, and D-edge finishing to ensure durability and safety.

8. How small can the machined features be?

Micro-machining and laser drilling achieve features as small as 100 µm, suitable for microfluidic or MEMS integration.

9. Does TiHot support small-batch or prototype orders?

Yes. We provide R&D-scale and pilot-run quantities with fast turnaround and engineering support.

Customizable Eagle XG® Wafer Dimensions

| Parameter | Customizable Range | Notes |

|---|---|---|

| Shape | Round / Square / Irregular | Based on drawing (DXF / STEP) |

| Diameter (Round) | 10 mm – 300 mm | 2″, 4″, 6″, 8″ common sizes |

| Side Length (Square) | Up to 300 mm | Rectangular or square |

| Thickness | 0.2 mm – 1.1 mm | Ultra-thin or standard available |

| Thickness Tolerance | ±0.01 mm – ±0.05 mm | Optical grade available |

| Edge Options | Ground / Chamfered / C-edge / D-edge | For safe handling & alignment |

| Surface Finishing | As-cut / Ground / Polished / Optical | Ra ≤ 0.01 µm optional |

| Drilling/Hole Size | ≥ 0.1 mm diameter | Microhole arrays supported |

| Coating Services | ITO / FTO / AR / Dielectric | Applied upon request |

| Packaging | Cleanroom-grade with barcode/label | Double-side protection film optional |

All Corning Eagle XG® wafers are made-to-order. TiHot supports fast prototyping, small-batch production, and full OEM service.

Leave Your Message