产品: B270 coating monitor glass

Featured products

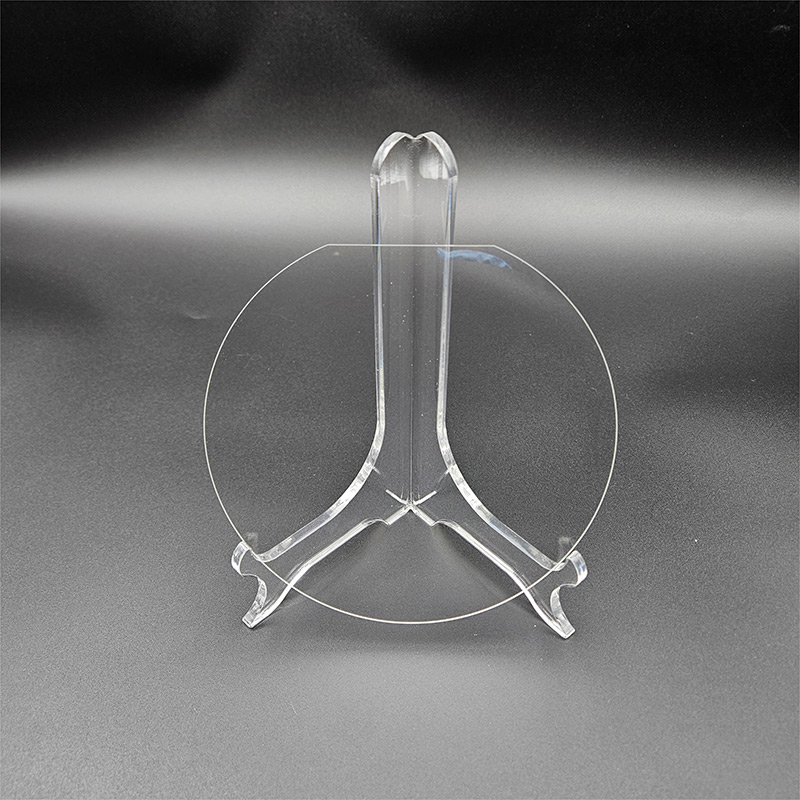

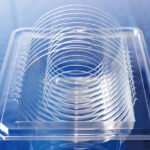

B270 coating monitor glass

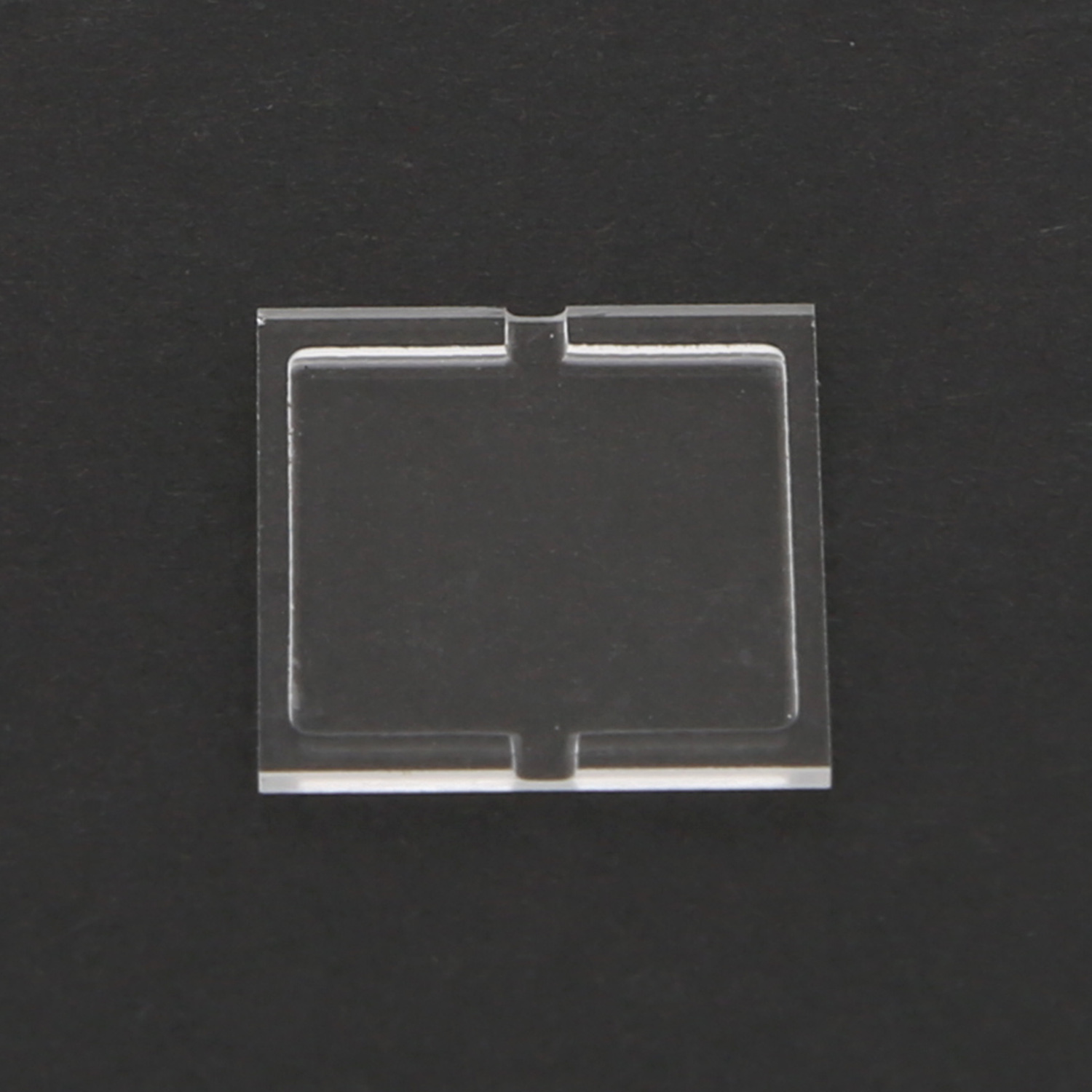

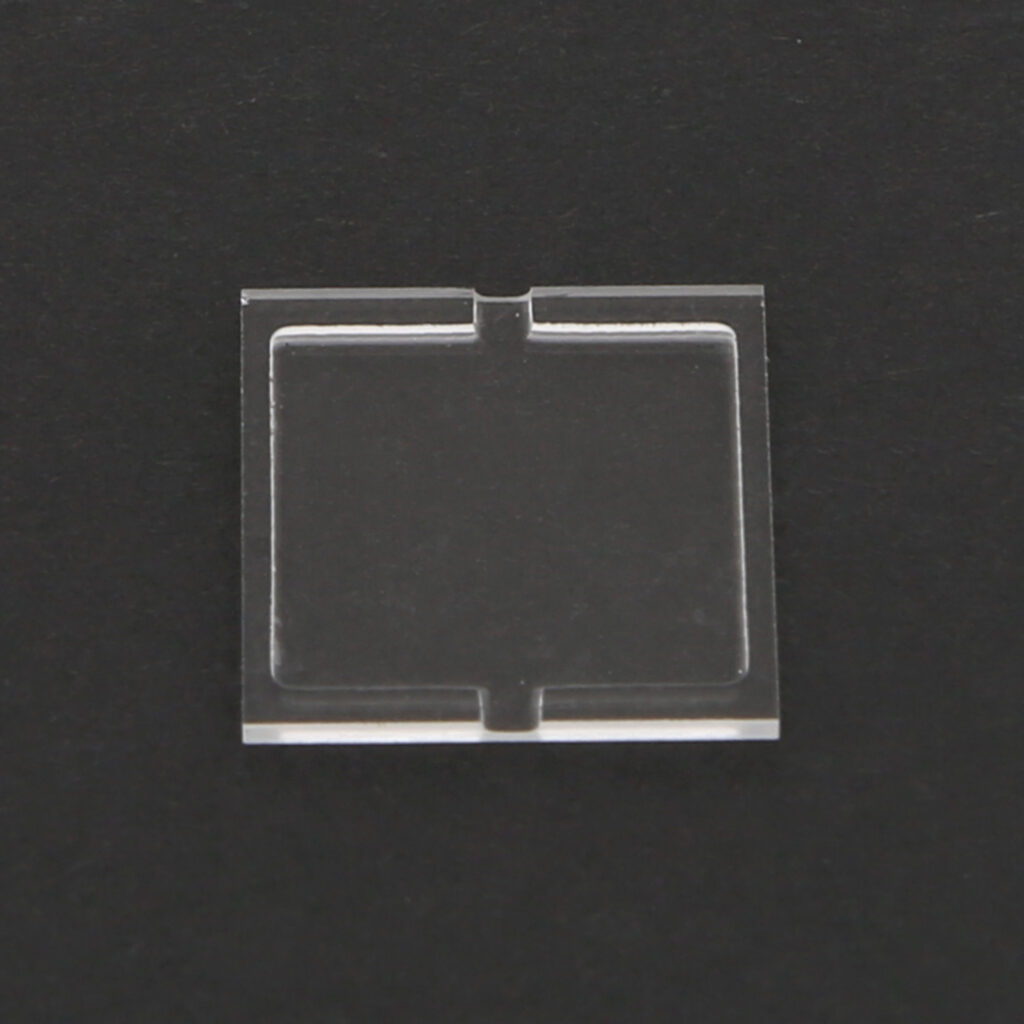

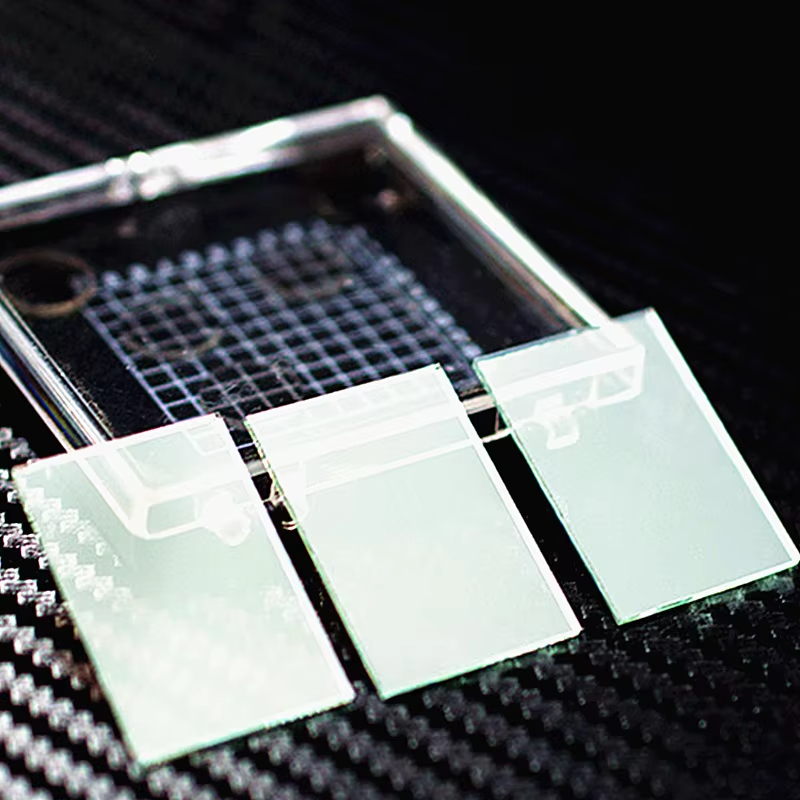

It is mainly applied to the thickness monitoring of the coating layer on the coating machine. The typical sizes are: 142*80*2.0mm and 155*90*2.0mm.

What Is Glass Plate for Film Thickness Monitoring?

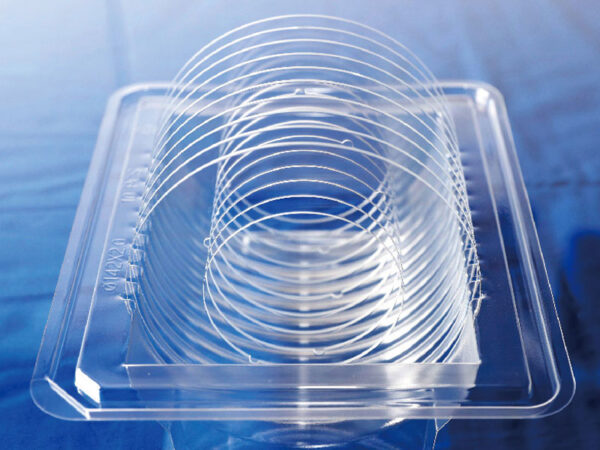

A glass plate for film thickness monitoring is a precision optical substrate used in vacuum coating systems to measure the thickness of deposited films. These plates undergo advanced cutting, grinding, and polishing processes to ensure excellent surface flatness, dimensional accuracy, and optical clarity.

Used as witness plates in deposition chambers, they enable real-time tracking of coating thickness without interfering with the actual production components. These substrates are vital in ensuring uniformity, repeatability, and process control in thin-film applications.

Key Features of SCHOTT B270 Glass Plates

The SCHOTT B270® crown glass is one of the most widely trusted materials in the optical industry for thin-film monitoring. It’s favored not only for its high visible-range transmittance but also for its chemical purity and uniform refractive index. This makes it particularly effective for applications involving spectrophotometric or ellipsometric measurement of coating thickness.

Our B270 monitor plates are optimized for:

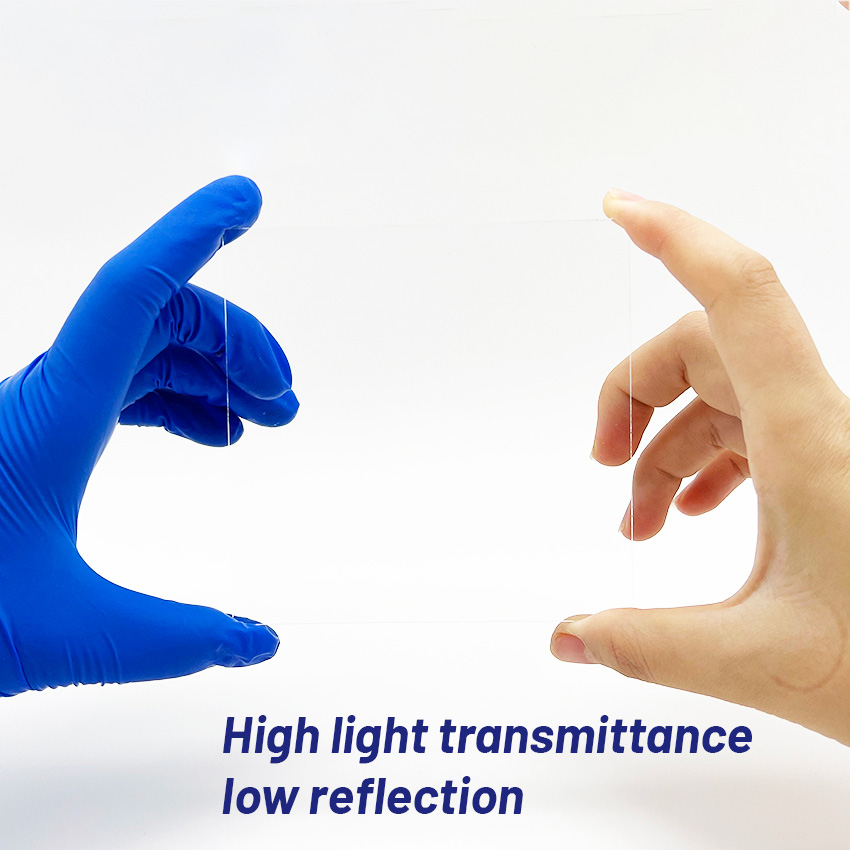

- High optical transmission, especially in the visible spectrum, ensuring accurate interaction with monitoring light beams.

- Extremely low autoluminescence, which is crucial in preventing signal distortion during interference-based thickness measurements.

- Excellent thermal and mechanical stability, enabling the glass to maintain shape and clarity even under repeated high-temperature deposition cycles.

- Superior surface quality and flatness, critical for ensuring that any optical signal passing through the substrate remains undistorted.

- Strong chemical resistance, particularly to the reactive environments within vacuum chambers, allowing the plates to be reused multiple times without degradation.

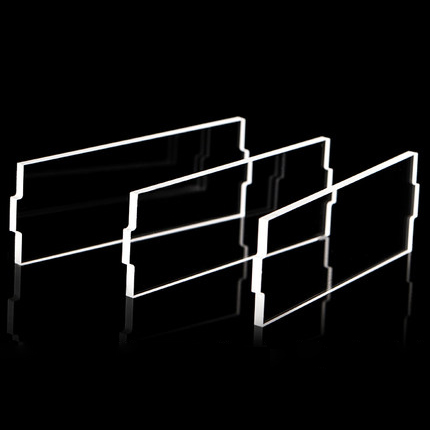

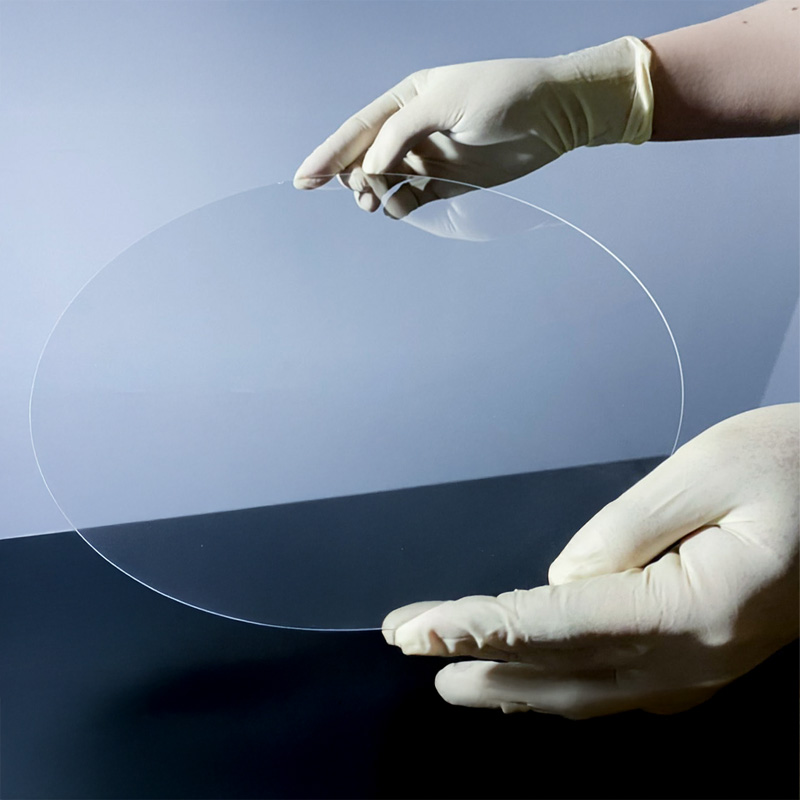

Precision Processing for Industrial Applications

To meet the stringent requirements of optical monitoring systems, each B270 glass plate is manufactured under strict process control. We begin with CNC cutting, which ensures tight tolerances and reproducible sizing. This is followed by double-sided lapping and polishing, which refines both surfaces to atomic-level smoothness—often achieving surface roughness below 10 angstroms.

We also apply edge chamfering and corner rounding, which not only makes the glass safer to handle but also reduces the risk of edge chipping during installation or cleaning. Every plate undergoes laser flatness inspection, ensuring it meets optical-grade specifications before final cleanroom packaging, which prevents contamination during transport and storage.

Standard Dimensions (Custom Sizes Available)

| Size (mm) | Thickness (mm) | Application Use |

|---|---|---|

| 142 × 80 | 2.0 | Optical monitoring slot |

| 155 × 90 | 2.0 | Vacuum deposition setup |

Main Applications in Thin-Film Coating Systems

One of the most common uses for these B270 plates is real-time film thickness monitoring. In optical monitoring systems, light is passed through or reflected off the witness plate, and any interference pattern generated provides real-time data on the growth of the coating. This non-contact approach allows the coating process to be continuously adjusted for optimal uniformity and adherence to design specs.

Another valuable application is their use as support substrates in sputtering systems. Because of B270’s excellent mechanical stability, these plates can act as rigid carriers for fragile or experimental materials. Their ability to withstand both mechanical and thermal stress ensures they maintain structural integrity throughout long deposition cycles.

Why Choose SCHOTT B270 Glass for Optical Monitoring?

Unlike common soda-lime or basic borosilicate glass, SCHOTT B270 is engineered for applications that demand optical precision and environmental resilience. It has an inherently low iron content, reducing unwanted light absorption and allowing more accurate spectral readings. The glass is also optically homogeneous, meaning its refractive index remains consistent across the substrate—an important factor in minimizing measurement drift and ensuring precise control in multilayer deposition.

Additionally, SCHOTT B270 exhibits no birefringence, which is essential for polarization-sensitive monitoring setups. Its compatibility with a broad range of wavelengths, including UV, visible, and near-infrared, further extends its usefulness across industries and applications.

Its polished surface is also ideal for additional coatings, such as anti-reflective (AR), dielectric, or conductive layers, allowing system integrators to customize each plate for the needs of their optical configuration.

Customization Options for OEM & Research Use

We offer full customization for industrial integration and R&D needs:

- Custom Dimensions & Thickness

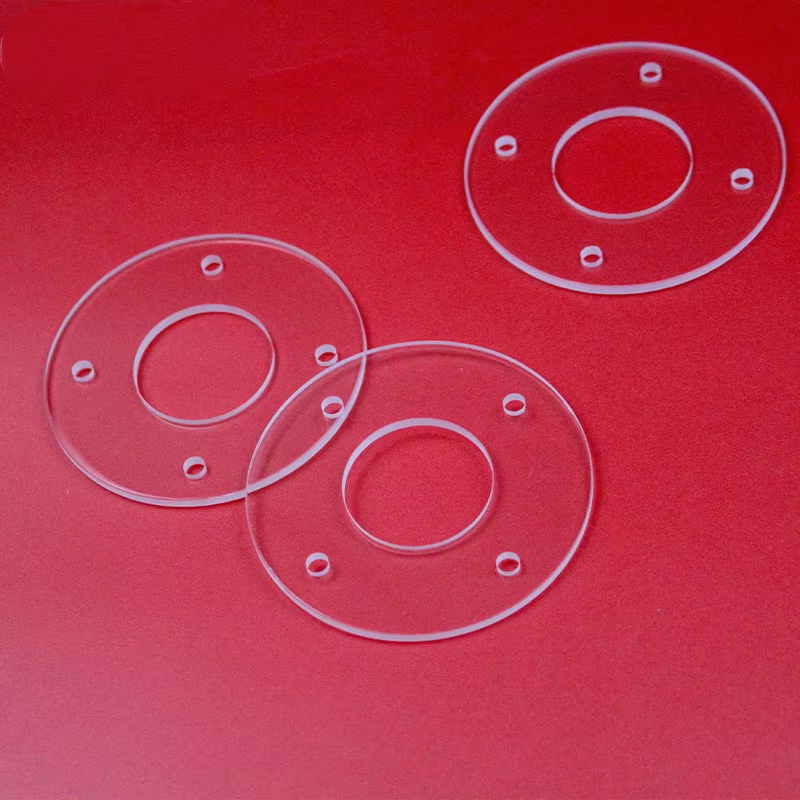

- Through-Hole Drilling for Mounting

- Surface Coatings: AR, ITO, DLC, etc.

- Laser Marking for ID and Traceability

Our engineering team works closely with OEM clients and researchers to ensure every specification meets your system requirements.

People Also Ask

What is SCHOTT B270 glass used for?

It’s widely used for thin-film optical coatings, monitoring windows, and high-quality optics where transparency and surface quality are critical.

Why choose B270 over soda-lime glass?

B270 offers superior optical clarity, flatness, and chemical durability, making it more suitable for demanding vacuum environments.

Can B270 plates be coated?

Yes. They are compatible with AR, dielectric, and conductive coatings, and their smooth surface enhances adhesion and coating uniformity.

Do you support OEM volume orders?

Absolutely. We support bulk production with tight tolerances and scalable capacity for industrial clients.

Is B270 glass UV-compatible?

Yes. B270 has high transmission down to ~320 nm, making it suitable for many UV and visible range applications.

Leave Your Message