产品: CCD Optical Screening Machine Glass Plate – High Flatness & Load Capacity

Featured products

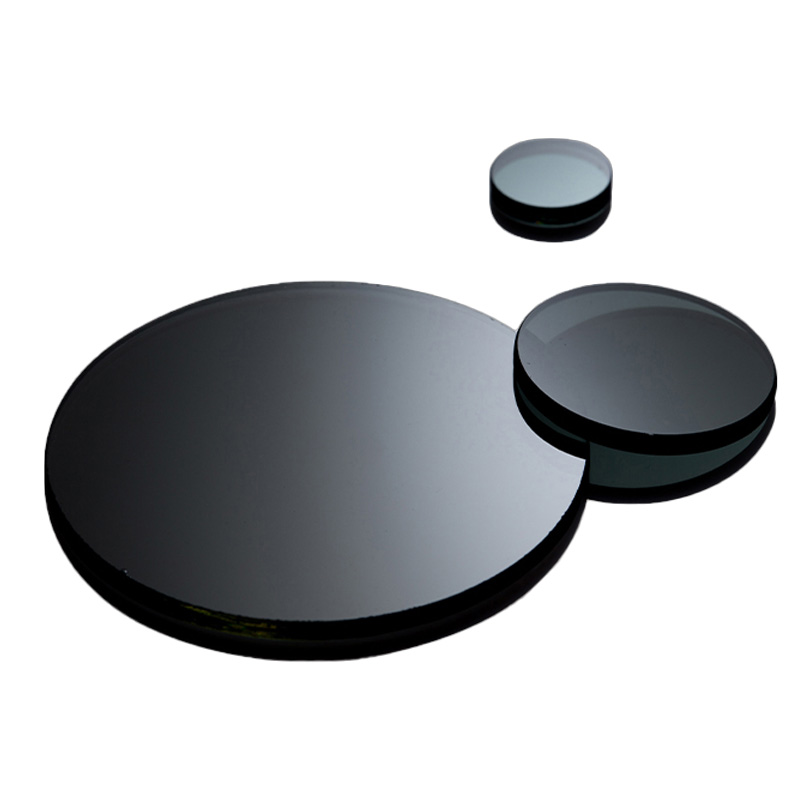

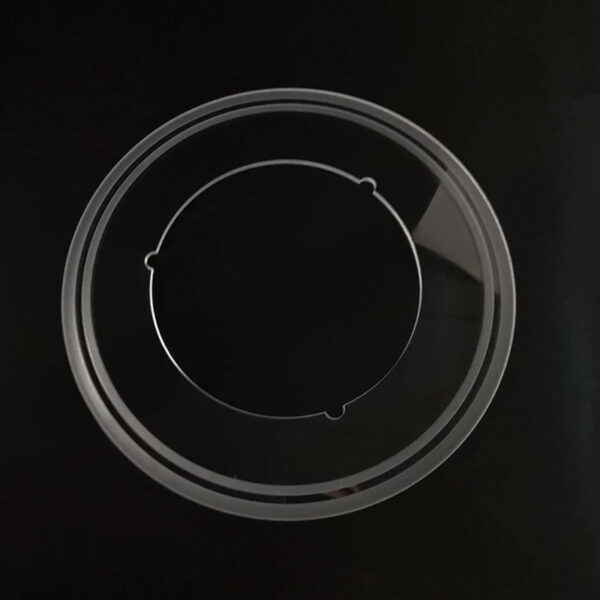

CCD Optical Screening Machine Glass Plate – High Flatness & Load Capacity

| Feature | Value |

|---|---|

| Light Transmittance | 92% – 98% |

| Glass Load Capacity | Up to 30KG |

| Surface Flatness | 0.10mm – 0.20mm |

| Equipment-Level Flatness | 0.01mm – 0.03mm (valid bounce rate) |

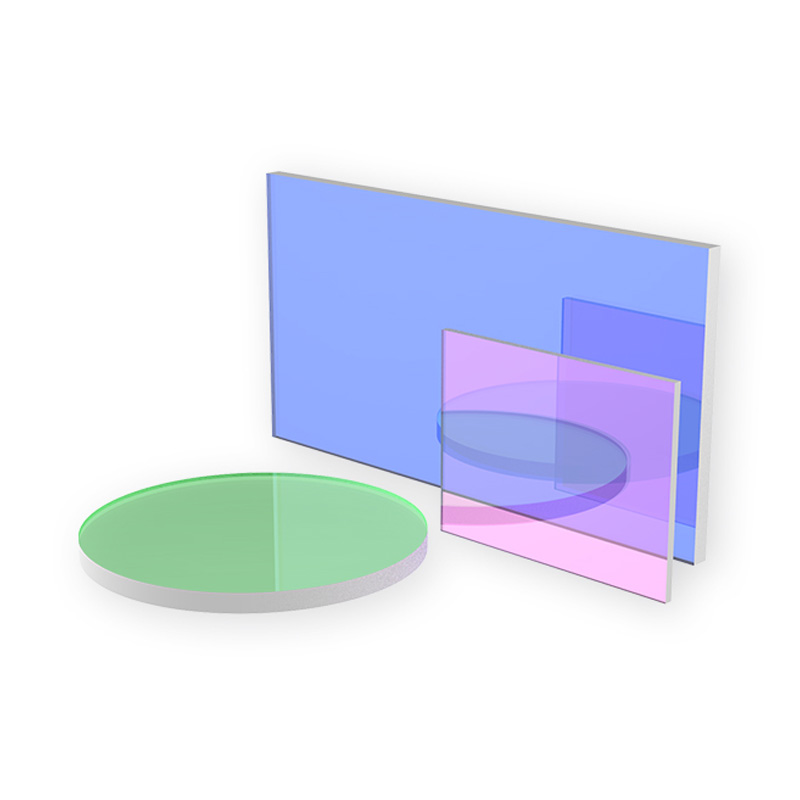

| Available Materials | Optical Borosilicate, Quartz, Float Glass |

| Edge Finish Options | CNC Polished, Beveled, Chamfered |

| Thickness Range | 1mm – 10mm (Custom Available) |

| Standard Sizes | 100×100mm, 200×200mm, Custom |

| Optional Coatings | AR (Anti-Reflection), Hardcoat, Oleophobic |

Every specification is selected to meet the stringent requirements of machine vision systems where dimensional accuracy, vibration resistance, and optical purity are non-negotiable.

Introduction to CCD Optical Screening Machine Glass Plates

In the high-precision domain of industrial visual inspection, the CCD Optical Screening Machine Glass Plate serves as a cornerstone component. This optical-grade substrate is meticulously engineered to deliver unmatched performance in image clarity, mechanical stability, and flatness—ensuring optimal conditions for Charge-Coupled Device (CCD) cameras used in inspection, sorting, and testing equipment.

As a trusted solution across semiconductor packaging, display module testing, PCB inspection, and automated optical inspection (AOI), these glass plates facilitate defect-free visual data acquisition even under high-load and high-speed industrial workflows.

What Is a CCD Inspection Glass Plate?

A CCD inspection glass plate is a custom-manufactured optical component designed to interface with vision systems that rely on CCD cameras for image capture and analysis. Its primary role is to serve as a transparent yet rigid base through which imaging sensors acquire high-resolution images of objects or components on an inspection line.

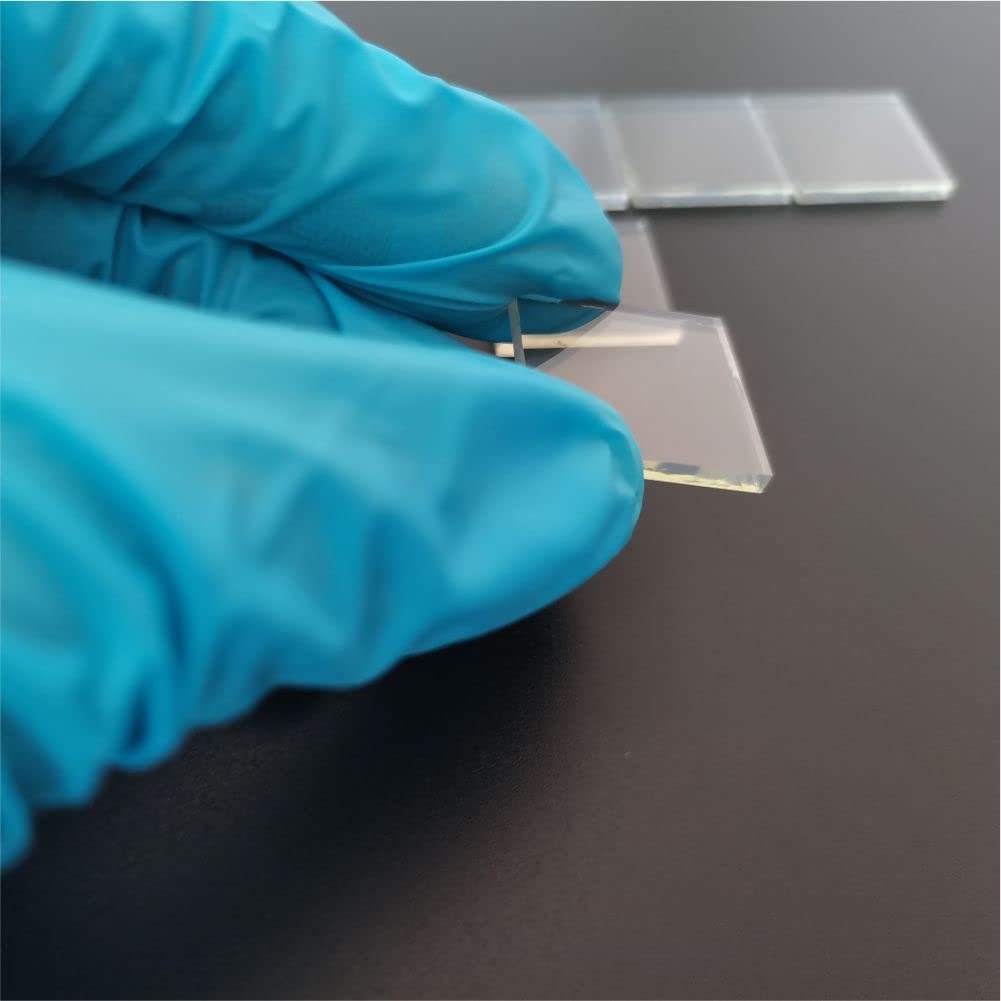

Made from materials such as optical borosilicate glass, float glass, or quartz, the plate provides optical transparency ranging from 92% to 98% in the visible spectrum, coupled with excellent dimensional stability, scratch resistance, and load-bearing capabilities.

Top-Tier Advantages of Optical Glass Plates for CCD Cameras

Ultra-High Flatness for Imaging Precision

Achieving 0.01mm–0.03mm flatness at equipment level ensures that the optical axis of CCD systems remains undistorted. This eliminates bounce-related artifacts, enhances image consistency, and supports precise object localization in AI-powered visual systems.

Superior Light Transmission

Thanks to its optical-grade surface polishing and high-purity materials, the glass plate permits maximal light throughput, which is crucial for capturing fine visual details in low-contrast or reflective objects.

Load-Bearing Durability

Whether deployed in conveyor-based scanning systems or robotic inspection arms, this glass can handle up to 30KG static or dynamic load without deflection or surface damage. This makes it ideal for automated high-throughput environments.

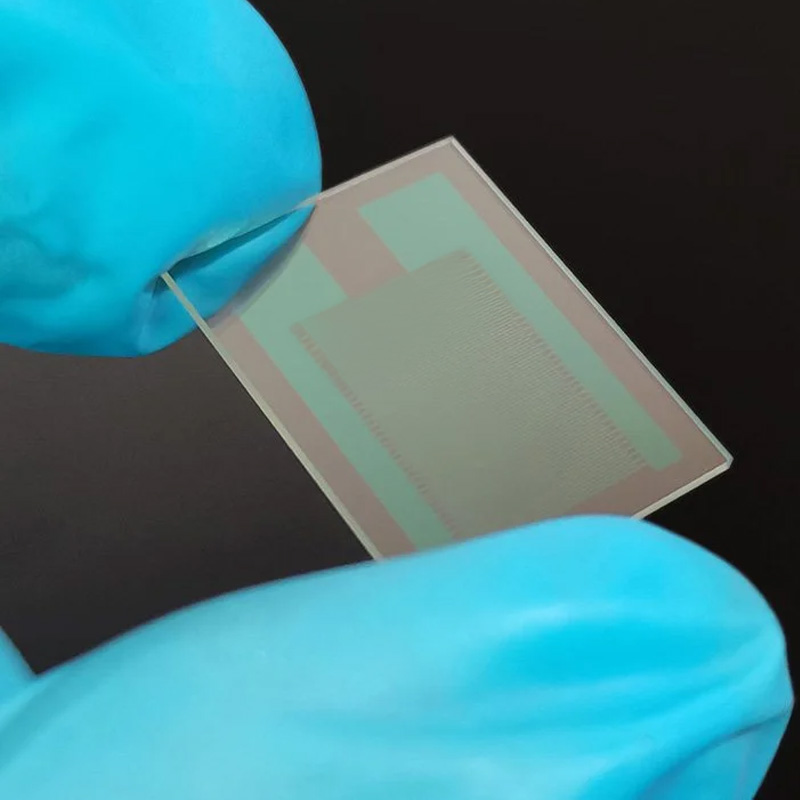

Precision-Machined Edges and Coating Options

With CNC-polished edge treatments, the plates resist chipping, cracking, and contamination ingress. Custom coatings like anti-reflective (AR), oleophobic, and hardcoat layers provide added durability, anti-smudge performance, and enhanced optical clarity.

Cleanroom-Ready Finish

Every unit is ultrasonically cleaned and packaged in Class 1000 cleanroom conditions, ensuring the glass arrives free from particulates, scratches, or organic residues—ready to integrate directly into your inspection system.

Primary Applications of Vision System Glass Plates

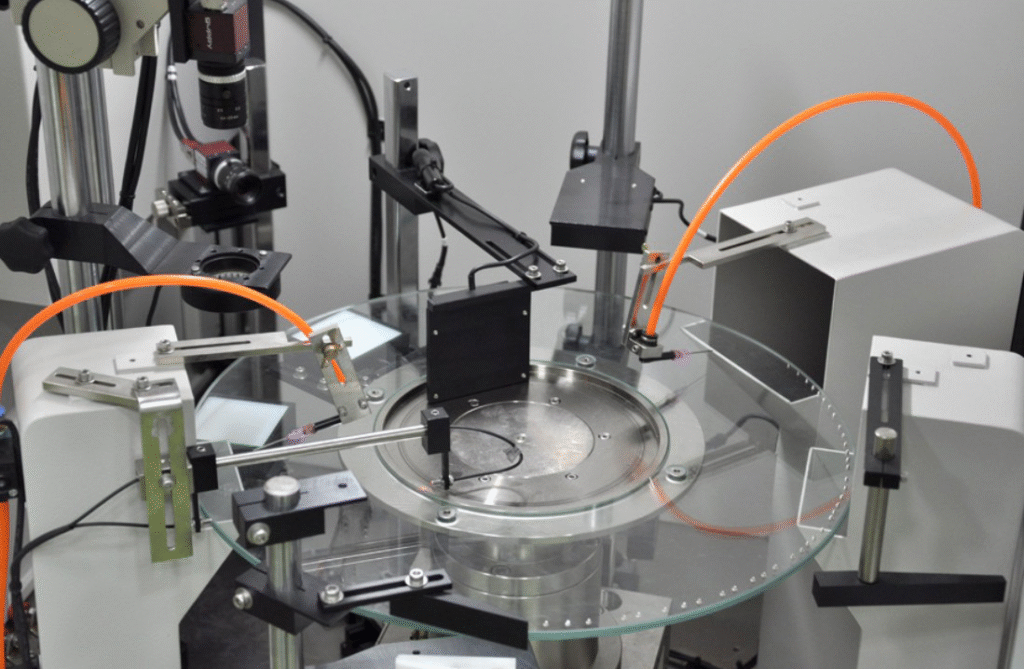

CCD Vision Inspection Equipment

Serves as a sensor window or substrate in inline automated visual inspection systems for electronics, pharmaceuticals, and automotive parts.

Display Module Testing

Used for inspecting LCD, OLED, and touch panels during post-assembly and pre-packaging stages with zero interference from the inspection substrate.

Semiconductor Wafer Inspection

Provides the ultra-flat, stable platform needed for silicon die inspection, BGA, QFN, or CSP packaging checks in semiconductor back-end processing.

Machine Vision Conveyor Systems

Forms the viewing window through which high-speed cameras scan parts, integrated seamlessly into pick-and-place or reject systems.

Why TIHOTOPTICS Is the Premier Choice for CCD Glass Plates

At TIHOTOPTICS, we don’t just supply optical glass—we engineer performance solutions tailored for CCD vision systems. Our team ensures every product passes stringent quality metrics, including:

- OEM and ODM customization for specific equipment requirements

- Tight tolerance control verified through interferometry and profilometry

- Rapid prototyping and delivery of standard models

- Comprehensive documentation for traceability and validation

- Dedicated engineering support for integration and retrofitting

Whether you’re upgrading legacy systems or building high-speed automation platforms, TIHOTOPTICS Glass Plates are the optimal choice for reliability, customization, and imaging precision.

FAQs

Q1: What methods are used to measure flatness in CCD applications?

We utilize high-resolution interferometers and laser flatness gauges to certify that each glass plate falls within the ±0.01mm–0.03mm equipment-level flatness range. This ensures consistent optical alignment in precision imaging systems.

Q2: Are anti-reflective coatings available?

Yes. We offer a full suite of optical coatings, including AR, anti-glare, and scratch-resistant coatings, tailored to your spectral wavelength requirements.

Q3: Can these glass plates be used in high-speed environments?

Absolutely. The mechanical integrity and vibration-resistant properties make them perfect for high-frequency, rapid-cycling inspection machines and automated robotics.

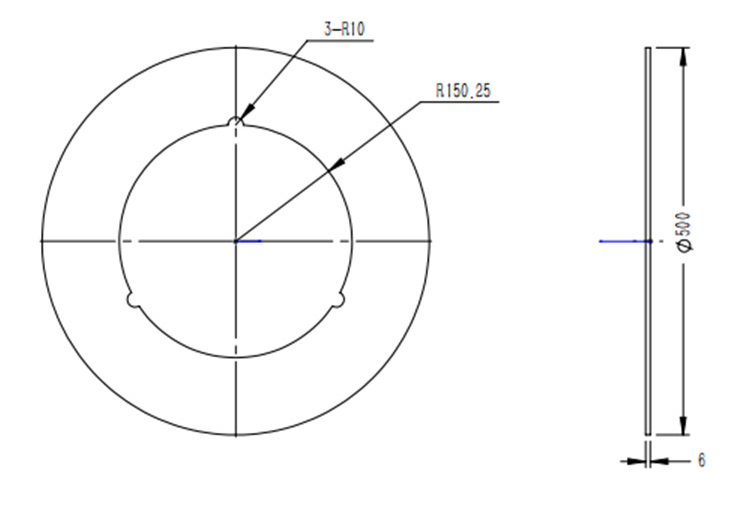

Q4: Is customization possible for shape, size, or cutouts?

Yes. We support fully customizable geometries, including non-rectangular forms, mounting holes, beveled corners, and more—precisely manufactured using 5-axis CNC and waterjet cutting technologies.

Leave Your Message