产品: Custom ITO Coating Glass

Featured products

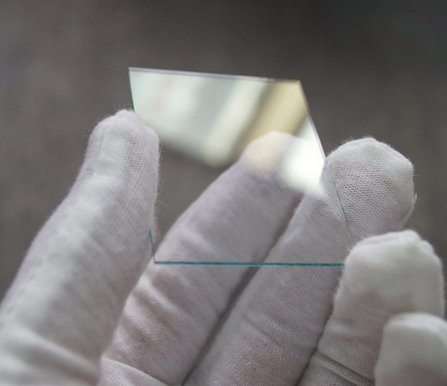

Custom ITO Coating Glass

| Parameter | Specification Range / Options |

|---|---|

| Substrate Material | Soda lime glass, Borosilicate (e.g. SCHOTT BOROFLOAT® 33), Quartz glass |

| ITO Film Composition | In₂O₃·(SnO₂)x |

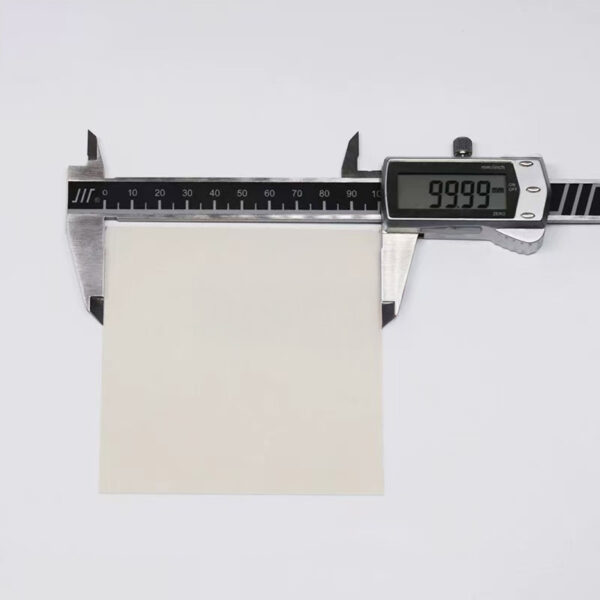

| Size (Customizable) | 10×10 mm to 300×300 mm (CNC cutting available) |

| Thickness | 0.4 mm / 0.7 mm / 1.1 mm / 1.8 mm / custom |

| Sheet Resistance (Ω/□) | 5–500 Ω/□ (custom sputtering) |

| Optical Transmission | ≥ 83% @ 550 nm |

| Surface Roughness | Glass < 1 nm RMS; ITO layer ≈ 1.8 nm RMS (AFM measured) |

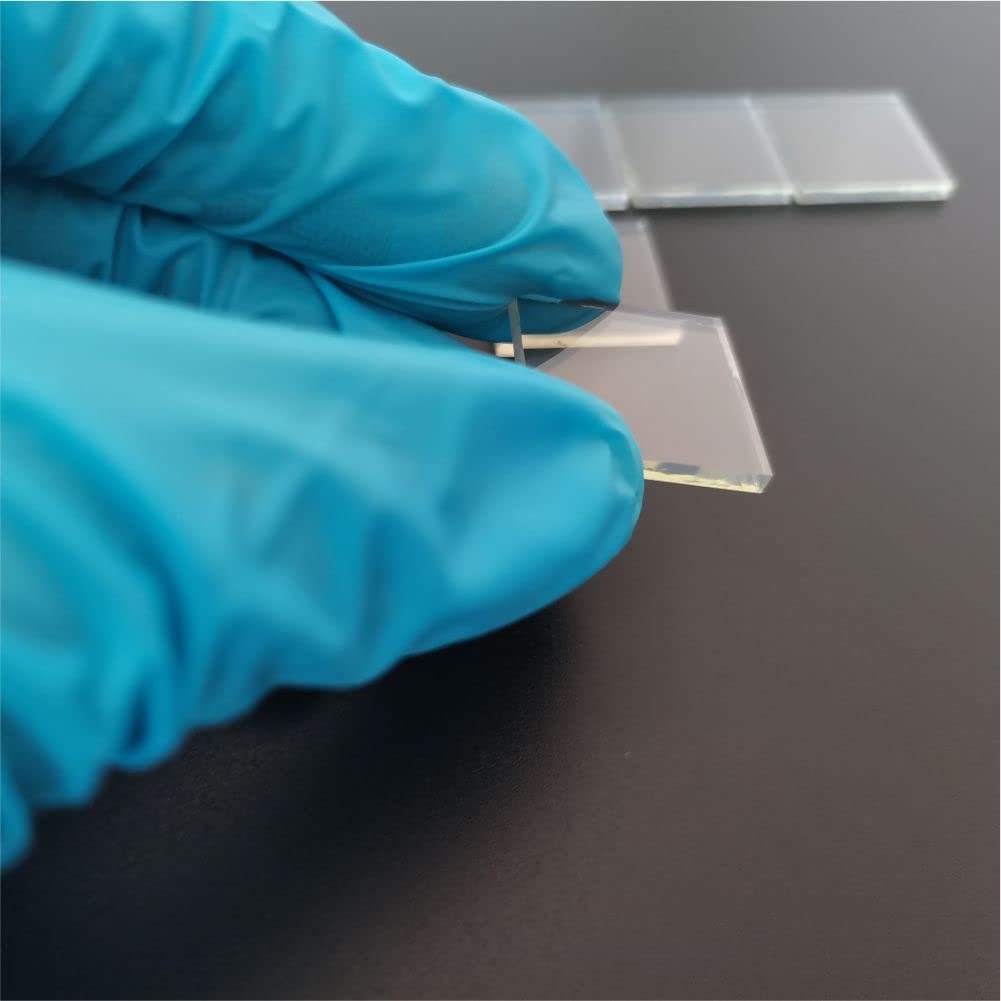

| Packing | 21 pcs/box (or custom packaging) |

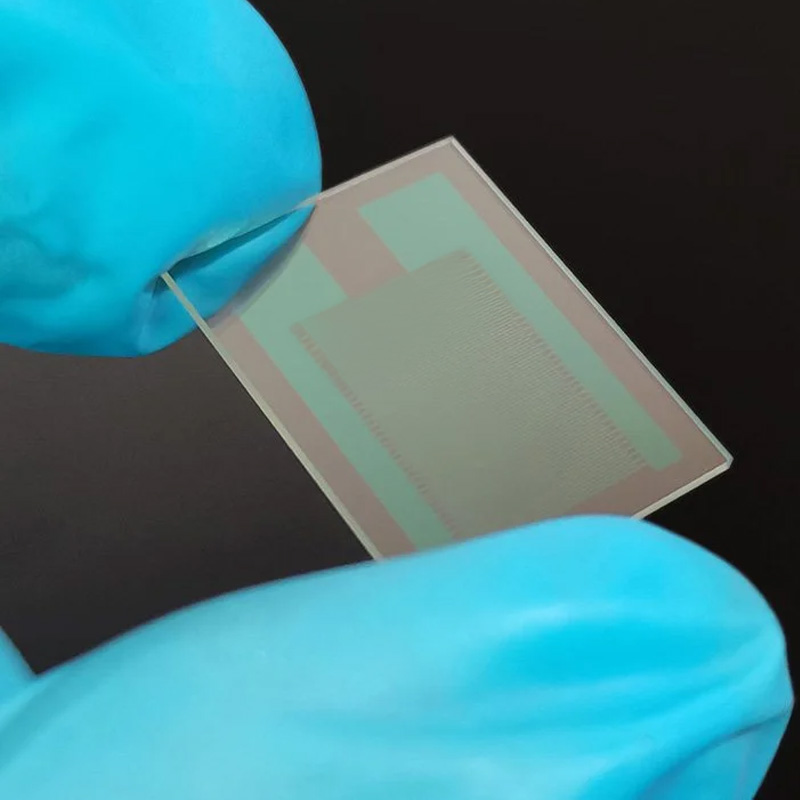

| Processing Capabilities | Laser cutting, edge grinding, polishing, pattern etching, coating, cleaning |

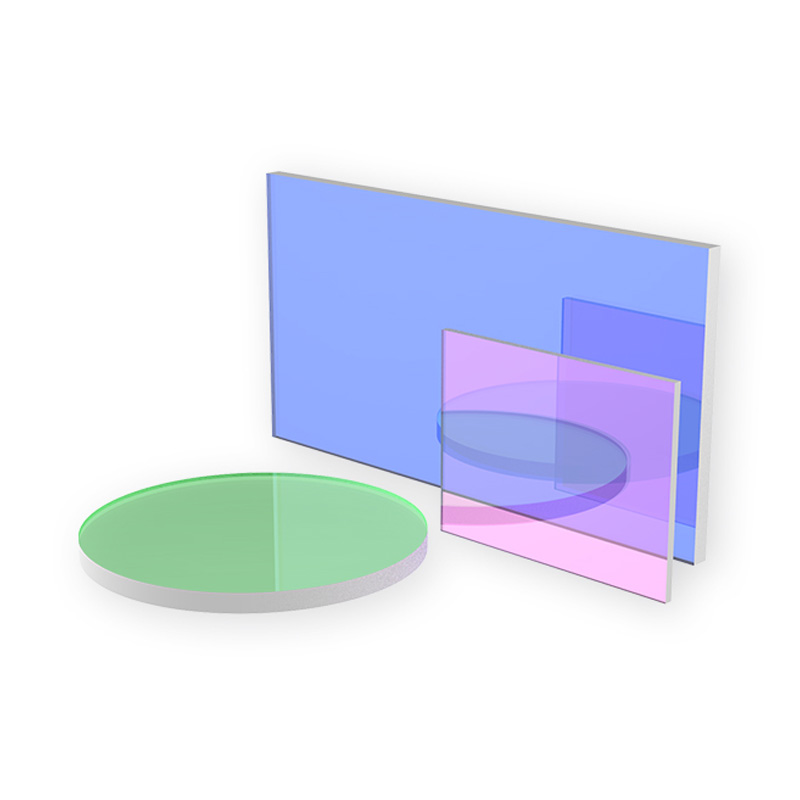

Custom ITO Glass Solutions for Precision Applications

Tihot Optics provides custom ITO conductive glass substrates tailored for advanced optical, electronic, and display applications. We combine high-transparency glass substrates with uniform indium tin oxide (ITO) coatings to deliver both excellent electrical conductivity and optical clarity.

Whether you need small prototype batches for research or mass production for industrial integration, our team ensures precise sheet resistance, stable transmission, and surface uniformity through advanced sputtering and cleanroom-controlled processes.

ITO Glass Features & Advantages

-

- High optical transmittance with stable surface resistance

-

- Excellent coating uniformity and adhesion

-

- Compatible with photolithography, etching, and thin-film processes

-

- Customizable sheet resistance and film thickness

-

- Suitable for both R&D and volume production

-

- Superior surface smoothness ideal for optoelectronic devices

Applications

Tihot Optics’ custom ITO glass is widely used in research, manufacturing, and high-tech product development.

Typical applications include:

-

- Touch panels and display covers

-

- Electro-optic and photovoltaic devices

-

- Heaters and transparent electrodes

-

- Microfluidic chips and biosensors

-

- Optical thin-film and MEMS applications

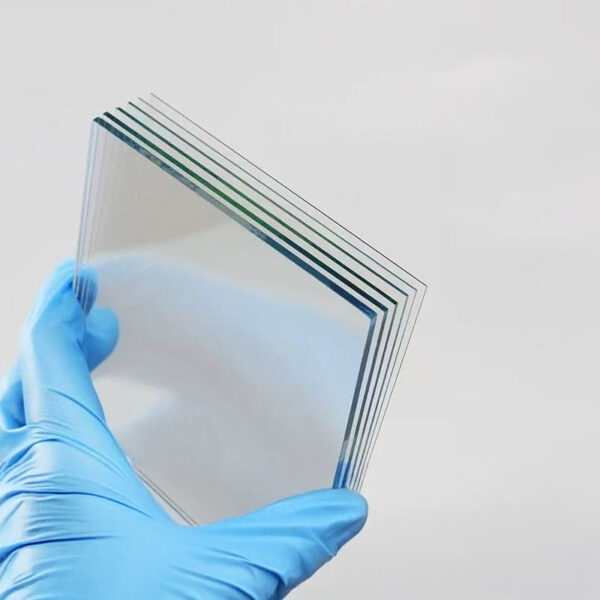

Precision Processing & Quality Control

Every ITO conductive glass substrate is fabricated under ISO-class cleanroom conditions using CNC cutting, ultrasonic cleaning, and advanced sputtering technology.

This ensures every glass piece meets the stringent optical and electrical standards required by modern devices.

Leave Your Message