产品: Custom LED Package Glass Cover Plate

Featured products

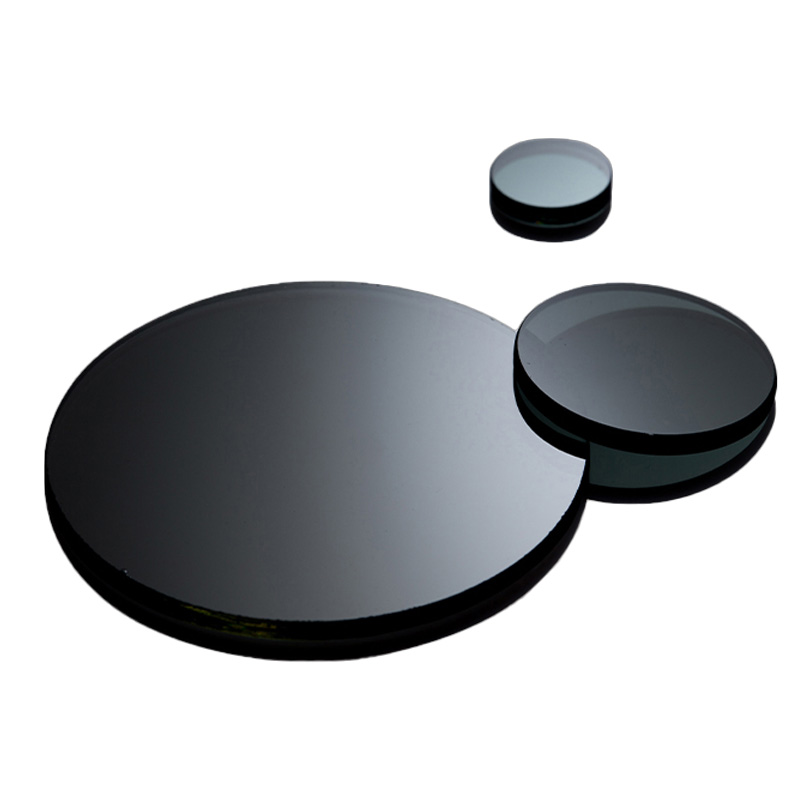

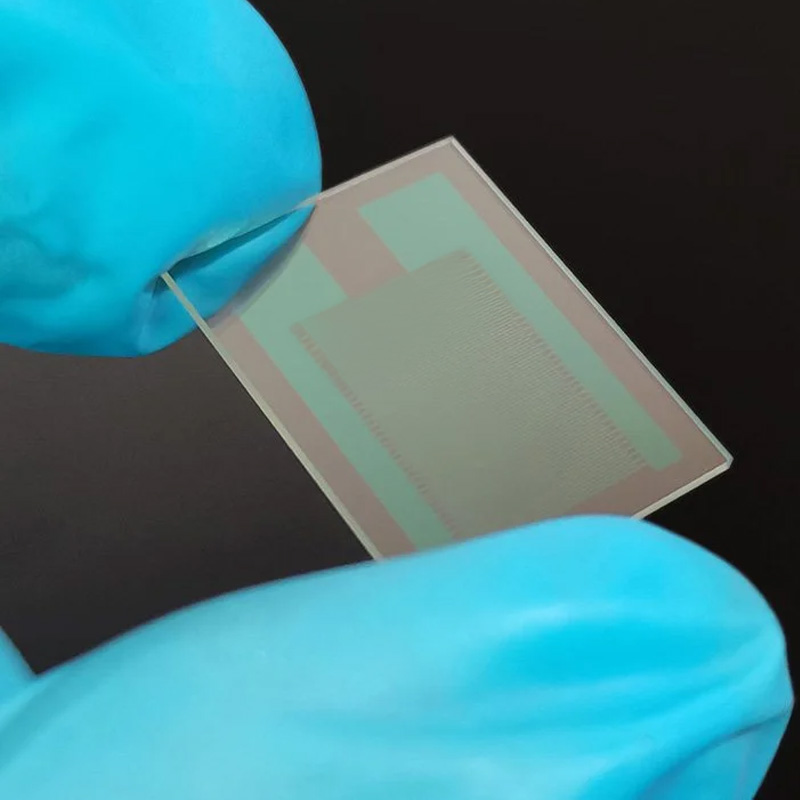

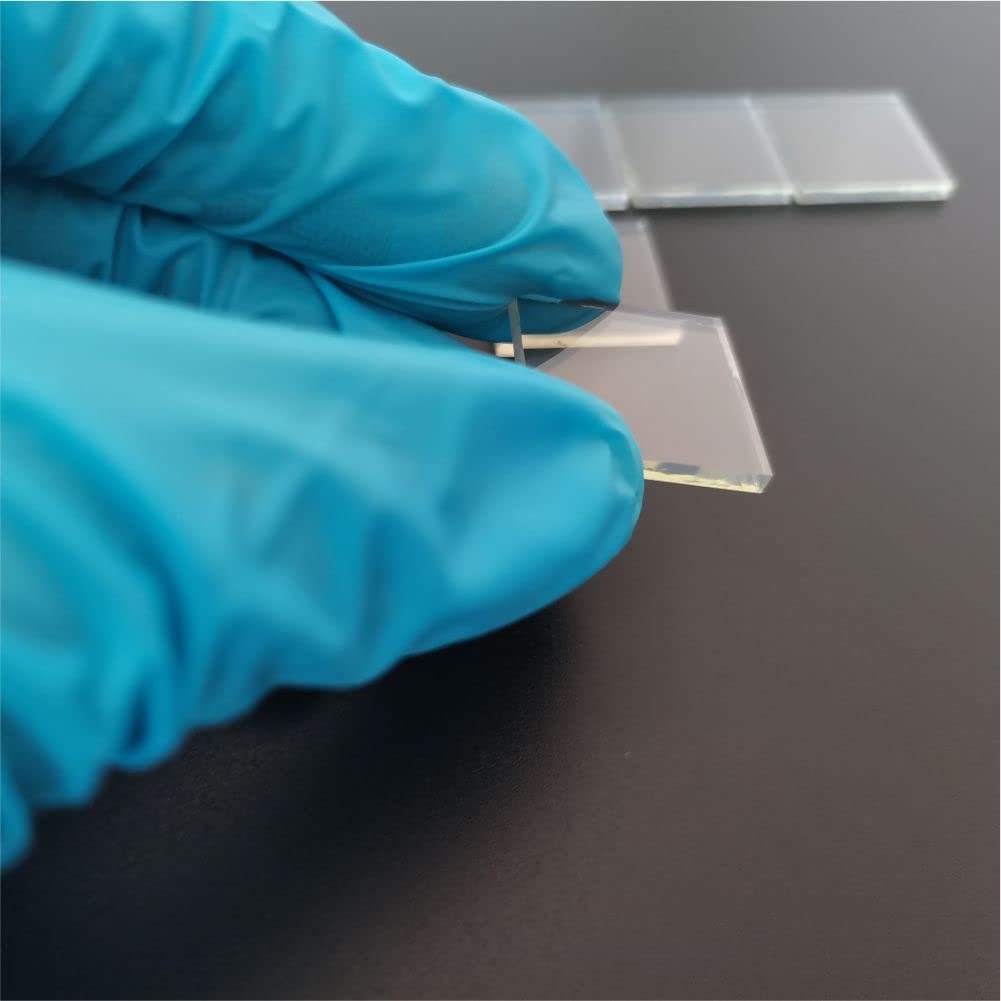

Custom LED Package Glass Cover Plate

| Property | Specification |

|---|---|

| Material | Borosilicate Glass / Quartz Glass / Aluminosilicate Glass |

| Thickness Range | 0.2 mm – 2.0 mm (customized) |

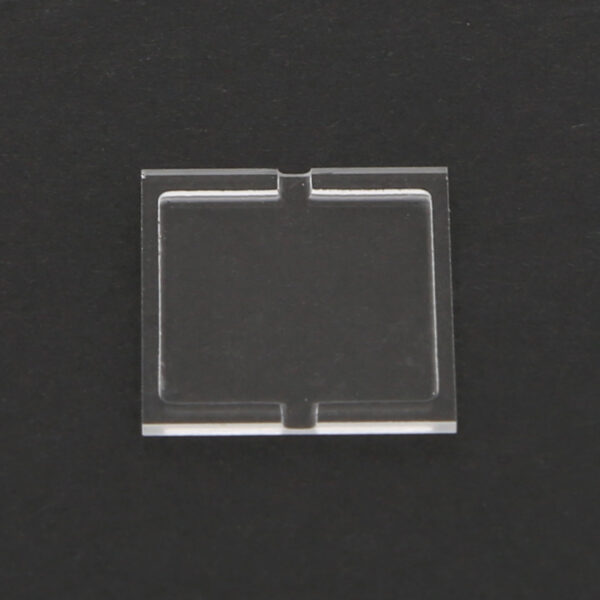

| Dimensions | Round, square, rectangle, custom shapes |

| Optical Transmission | > 92% (visible light) |

| Surface Roughness | Ra < 10 nm (higher precision available) |

Introduction: LED Package Glass Cover Plate

LED package glass cover plates are precision-engineered optical glass windows designed to protect LED chips while maintaining high light output. Compared to plastic covers, glass offers superior optical clarity, heat resistance, and long-term reliability, making it the preferred solution for high-power LEDs, laser diodes, and optoelectronic devices.

Glass vs. Plastic in LED Packaging

| Feature | Glass Cover Plate | Plastic Cover (Epoxy / PC) |

|---|---|---|

| Optical Transmission | >92% visible transmission, stable over time | Initially 88–90%, prone to yellowing and degradation |

| Thermal Stability | Withstands 500–800 °C soldering & operation | Typically <150 °C, limits high-power use |

| UV & Aging Resistance | Excellent UV resistance, no yellowing | Easily ages, cracks, or discolors |

| Hermetic Sealing | Enables hermetic package sealing | Generally non-hermetic |

| Customization | Supports coating, drilling, polishing, patterning | Limited by material properties |

Conclusion: Plastic covers work for cost-sensitive applications, but for high-performance optoelectronics, glass cover plates are the only reliable choice.

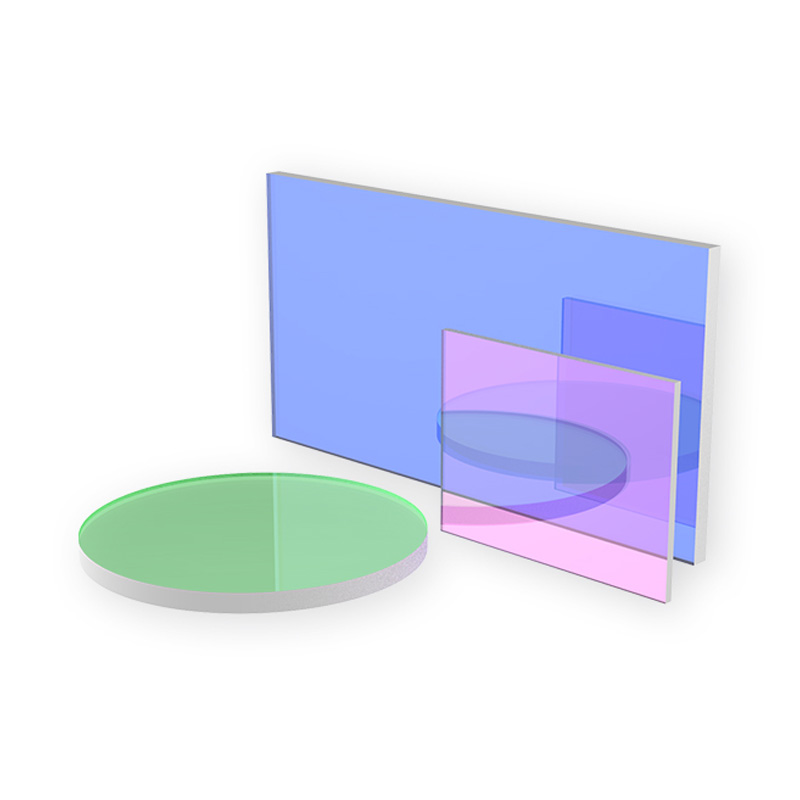

Material Science of LED Glass Covers

-

- Borosilicate Glass – Low thermal expansion (~3.3 ×10⁻⁶/K), cost-effective and reliable for general LED packaging.

-

- Quartz Glass (Fused Silica) – Ultra-pure, excellent UV transmission, ideal for UV-LEDs and laser diodes.

-

- Aluminosilicate Glass – High mechanical strength and durability, often used in automotive and portable devices.

The selection of glass is guided by optical transmission, coefficient of thermal expansion (CTE), and chemical resistance, ensuring compatibility with different packaging environments.

Applications Across Industries

Our high-transparency glass cover plates are available in various customized dimensions, making them suitable for a wide range of advanced packaging needs:

-

- High-Power LED Chip Packaging – Ensures stable optical output and reliability under extreme thermal conditions.

-

- High-Power Density Device Packaging – Provides durable protection for chips operating at elevated power loads.

-

- Integrated Circuit & MEMS Packaging – Supports microelectronic and micro-mechanical components with excellent sealing and optical performance.

Why Choose Us?

Our glass cover plates are designed with precision and reliability in mind, ensuring excellent performance across different LED packaging applications. Key advantages include:

-

- Tailored Optical Materials – Different glass types are selected to match various wavelength requirements, ensuring optimal light performance.

-

- Advanced Optical Processing – Unique optical machining and coating techniques deliver more uniform and balanced light projection.

-

- Stable High Transparency – Superior anti-aging properties keep light transmission stable over long-term use.

-

- Exceptional Durability – Resistant to acids, alkalis, and capable of withstanding high temperatures with excellent Mohs hardness.

-

- Custom Manufacturing – Available in multiple sizes and shapes, fully tailored to customer drawings and application needs.

FAQs

Q1: Why choose glass covers over plastic for LED packaging? A: Glass offers longer lifetime, higher optical stability, and better thermal resistance, reducing long-term system costs.

Q2: What is the typical lead time for custom sizes? A: Prototype samples can be delivered in 1–2 weeks, and mass production within 3–4 weeks.

Q3: Do you support coated and patterned glass covers? A: Absolutely – AR, ITO, and DLC coatings, as well as laser patterning and drilling, are available.

Leave Your Message