产品: custom Special Shaped Glass Plate

Featured products

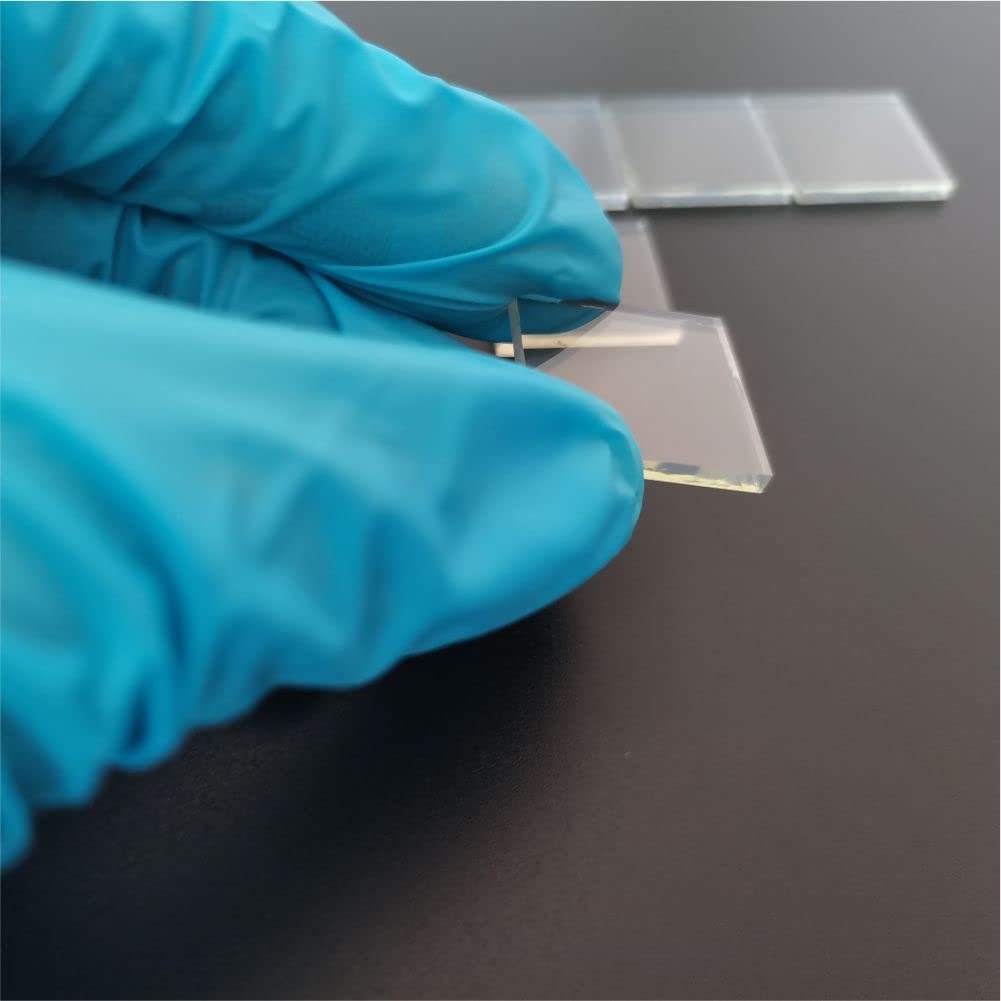

custom Special Shaped Glass Plate

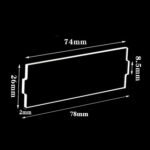

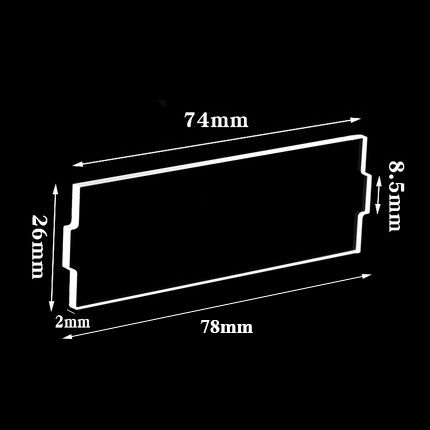

| Category | Capability / Range | Notes |

|---|---|---|

| Outline Size | 5–500 mm (longer upon request) | Rectangular or irregular profiles |

| Thickness | 0.20–10.0 mm | Standard: 0.5 / 0.55 / 0.7 / 1.1 / 2.0 / 3.0 mm |

| Step / Ledge Depth | 0.10–3.00 mm | Multi-level steps supported |

| Dimensional Tolerance | Outline ±0.05–0.15 mm; Step depth ±0.03–0.10 mm | Depends on thickness & geometry |

| Flatness / Warp | ≤0.2% of diagonal (typical) | Optical-grade on request |

| Surface Roughness | < 0.02 μm Ra (polished) | Lapped/etched finishes optional |

| Edges | C-chamfer / bevel / rounded R | Chip-free edges, safety finish |

| Holes / Slots | Ø0.8–30 mm; Positional tol. ±0.10 mm | Countersink/counterbore available |

| Strengthening | Chemical or thermal tempering | Per material & thickness |

| Coatings | AR/AG/AF, ITO heater/electrode, IR/UV-cut, DLC | Silk-print blackout frames optional |

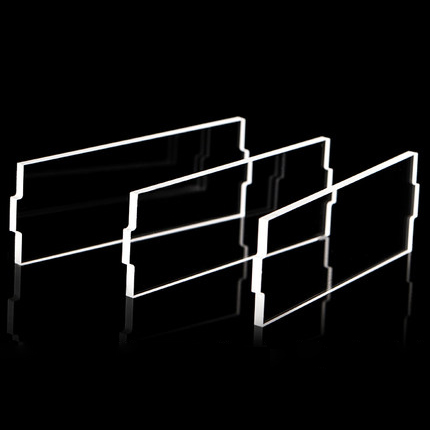

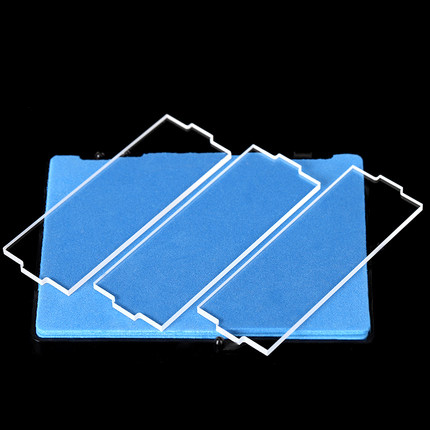

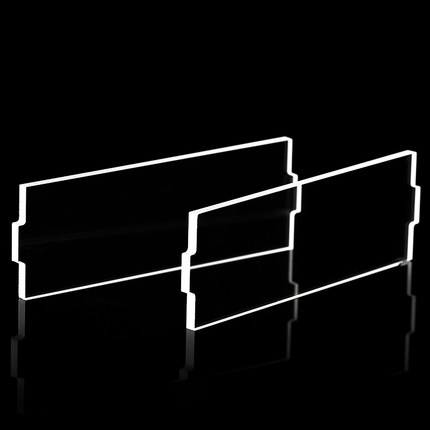

Custom Special-Shaped Glass Plate (Stepped / Notched / Irregular)

Engineered for assemblies that need precise locating edges, seal ledges, or stepped interfaces, our custom special-shaped glass plates are CNC-machined to your drawing and finished for optical, mechanical, or protective use. We support complex outlines (steps, notches, slots, radii), tight tolerances, and functional coatings for applications in medical diagnostics, machine vision, laser/optics, semiconductor tools, consumer devices, and automotive electronics.

Key Features

-

Precision shapes: steps, shoulders, ledges, keyways, countersinks, pockets, and through-holes

-

Tight tolerances on outline and step depth; excellent edge quality with controlled chamfers

-

Optical-grade polishing available (Ra < 0.02 μm) and low-defect surfaces for imaging windows

-

Strength options: chemical strengthening (thin aluminosilicate) or thermal tempering (thicker low-iron)

-

Coating options: AR/AG/AF, ITO heater/electrode, IR-cut/UV-cut, DLC hard coat, hydrophobic/anti-soiling

Material Options

-

Borosilicate (e.g., BOROFLOAT® 33): low CTE, chemical durability, bonding friendly

-

Aluminosilicate (e.g., SCHOTT D263T, Corning Eagle XG®): high strength, ultra-thin formats

-

Fused Silica / Quartz: ultra-low CTE, high purity, UV-to-IR transmission

-

Low-Iron Tempered Glass: high visible transmittance for covers and lighting windows

Typical Manufacturing Flow

CNC/waterjet rough-cut → precision grinding → step/ledge milling → fine grinding/polishing → edge finishing (C-chamfer, bevel, radius) → cleaning → optional strengthening (chemical/tempering) → functional coatings → inspection & packaging.

Applications

-

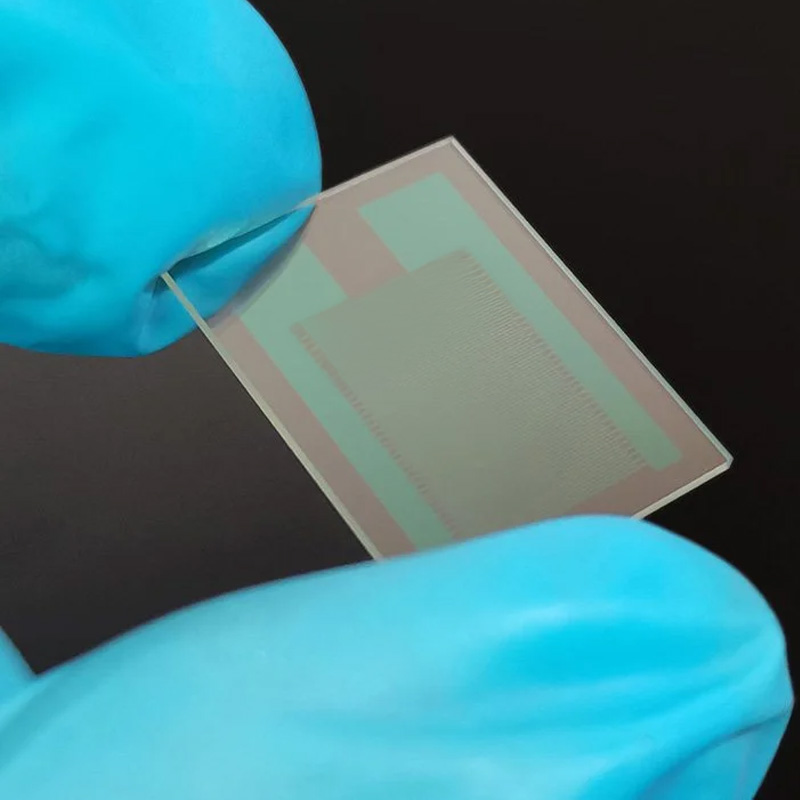

Medical & Analytical Instruments: sealed windows, reagent cartridge covers, flow-cell caps

-

Microfluidics & Bio-MEMS: stepped cover plates for alignment and hermetic sealing

-

Machine Vision / Sensors: protective windows with blackout silk-print and AR/AF

-

Optics & Laser Systems: durable viewports, beam covers, and heat-resistant shields

-

Handheld / Payment / Kiosks: scratch-resistant, easy-to-mount stepped covers

-

Automotive Electronics: camera/HUD covers with strengthened edges and coatings

Leave Your Message