产品: Etched Glass Cover for LED/OLED Module Packaging

Featured products

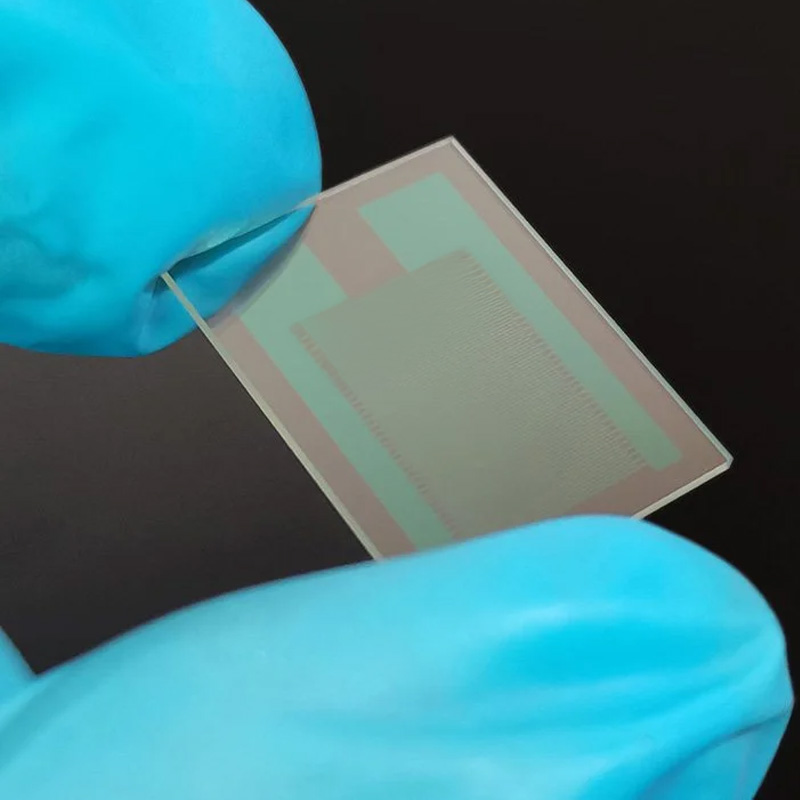

Etched Glass Cover for LED/OLED Module Packaging

Specification Data

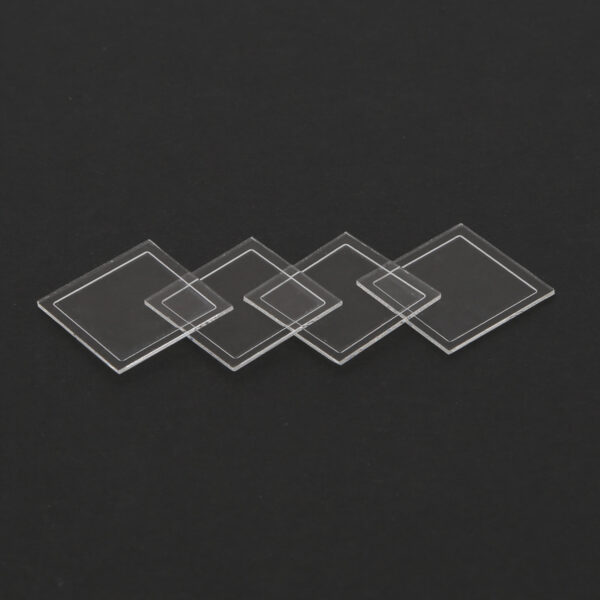

Thickness Range :0.2 mm – 2.0 mm

Max Dimensions Up to 200 mm × 200 mm

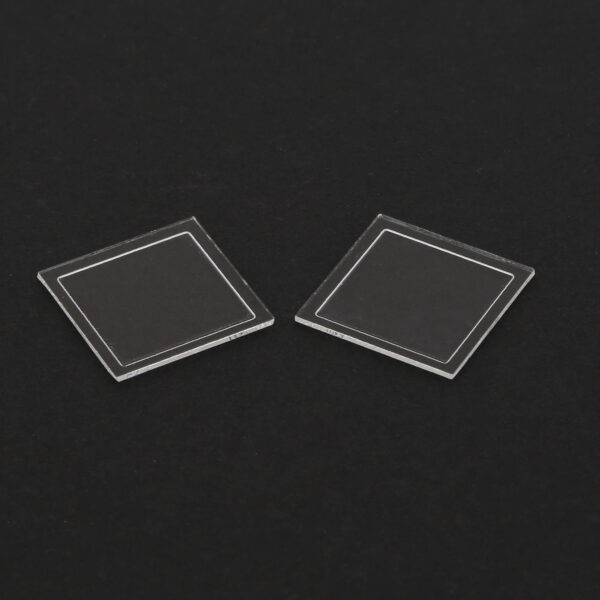

Material Options: B270®, D263T®, BOROFLOAT® 33, Quartz

Optical Transmission :≥ 90% (400–700 nm)

Etching Type Laser or Chemical, Depth 10–100 μm

Surface Finish Polished, AR-coated, Anti-glare optional

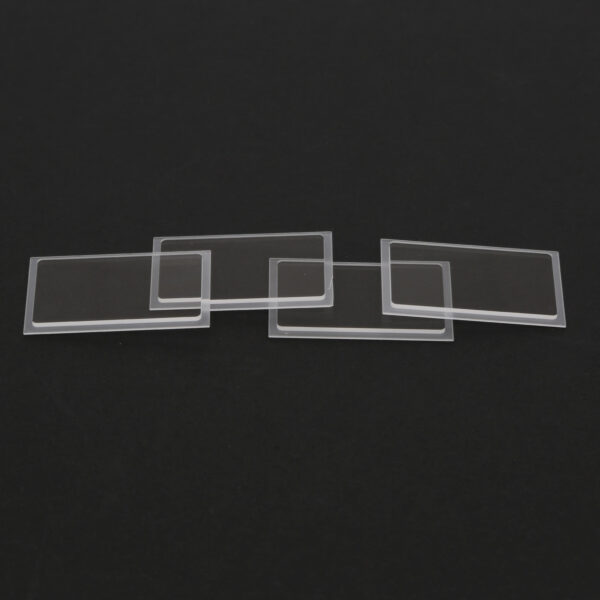

Edge Treatment Stepped, C-cut, Beveled, Embedded

Thermal Stability Up to 400°C (material dependent)

What Is an Etched Glass Cover for LED/OLED Module Packaging?

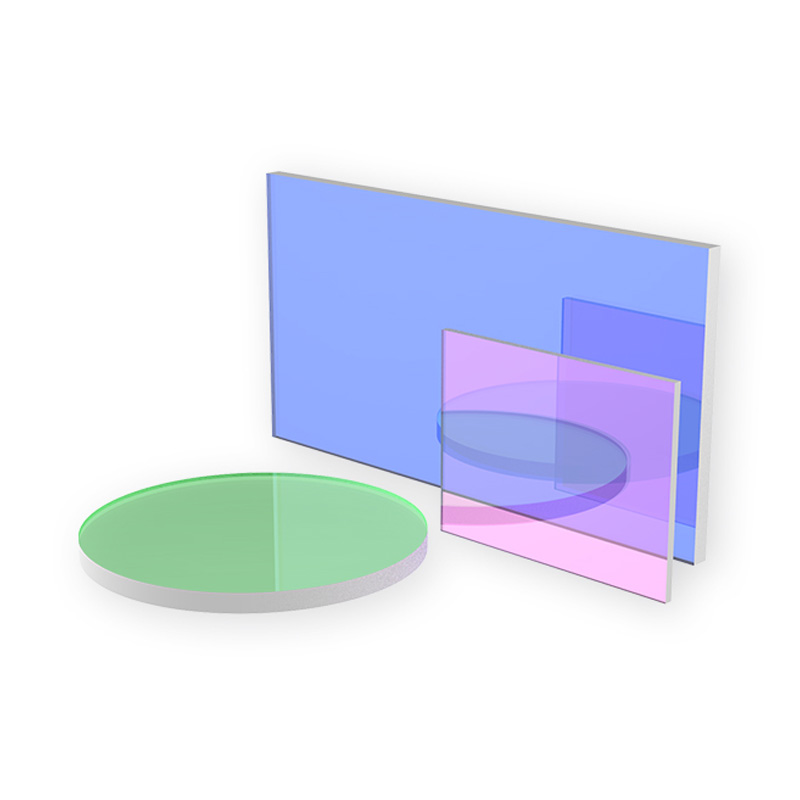

Etched glass covers are precision-processed glass substrates featuring micro-etched patterns or recessed geometries, specifically designed for use in LED and OLED module packaging. These covers serve as optical windows and protective layers during the encapsulation process, offering high light transmission, excellent bonding compatibility, and thermal durability.

An etched glass cover can include microgrooves, alignment marks, anti-glare textures, or embedded notches to optimize assembly and light performance.

TIHOTOPTICS provides custom etched glass covers tailored to various LED/OLED packaging demands.

What Is an Etched Glass Cover Used For?

Etched glass covers are ideal for:

- COB (Chip-on-Board) LED Packaging

- OLED Panel Encapsulation

- LED Filament Lamp Covers

- Mini- and Micro-LED Display Modules

- Optical Lens & Light Engine Assemblies

They enhance adhesion, improve light diffusion, and protect sensitive chip surfaces during thermal and mechanical processing.

Why Choose Etched Glass Covers for LED/OLED Packaging?

Etched glass covers provide several advantages:

- Enhanced Surface Bonding: Micro-etching improves adhesion with silicone, epoxy, and other optical encapsulants.

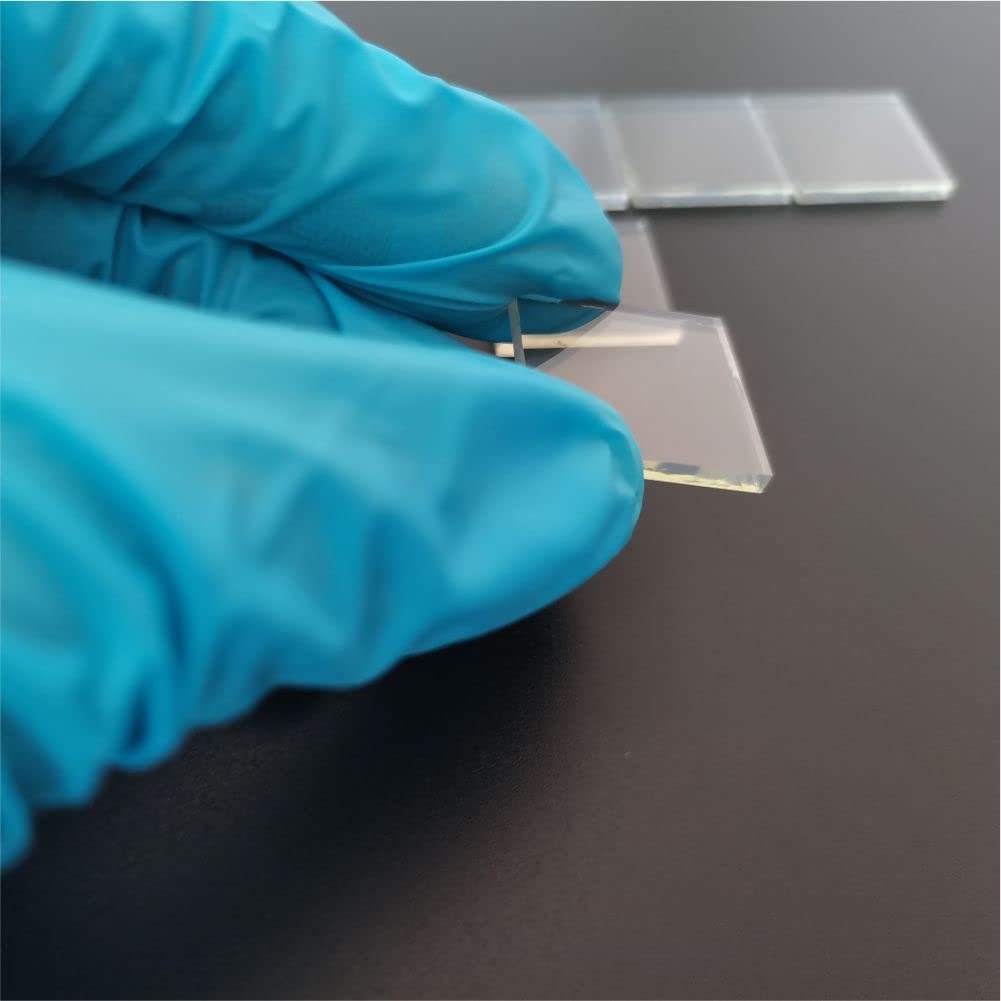

- Recessed/Embedded Features: Allow partial insertion into housing or lens mounts, improving assembly precision.

- High Optical Transmission: Over 90% visible light transmission ensures minimal optical loss.

- Heat & Chemical Resistance: Suitable for reflow soldering and UV-curing processes.

- Customizable Geometry: Supports circular, rectangular, slotted, or step-cut designs.

People Also Ask

What does an etched glass cover do in LED packaging?

It acts as a transparent seal and optical interface, improving bonding and reducing light scattering losses during LED or OLED packaging.

Can etched glass be used in OLED encapsulation?

Yes. Etched glass is suitable for OLED displays, where it offers low-stress bonding, high clarity, and chemical stability during encapsulation.

What materials are used for etched LED covers?

Common options include B270®, BOROFLOAT® 33, D263T™, and fused quartz—selected based on thermal needs and optical performance.

What’s the benefit of recessed glass in LED modules?

Recessed designs fit tightly into modules, improve optical alignment, and reduce stress on encapsulants.

Are custom shapes available for LED covers?

Yes. Shapes such as round, square, or with notches, slots, or stepped sides are fully customizable based on module design.

Leave Your Message