产品: High Content Screening Microplates with Glass Bottom

Featured products

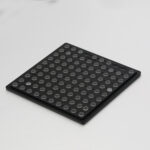

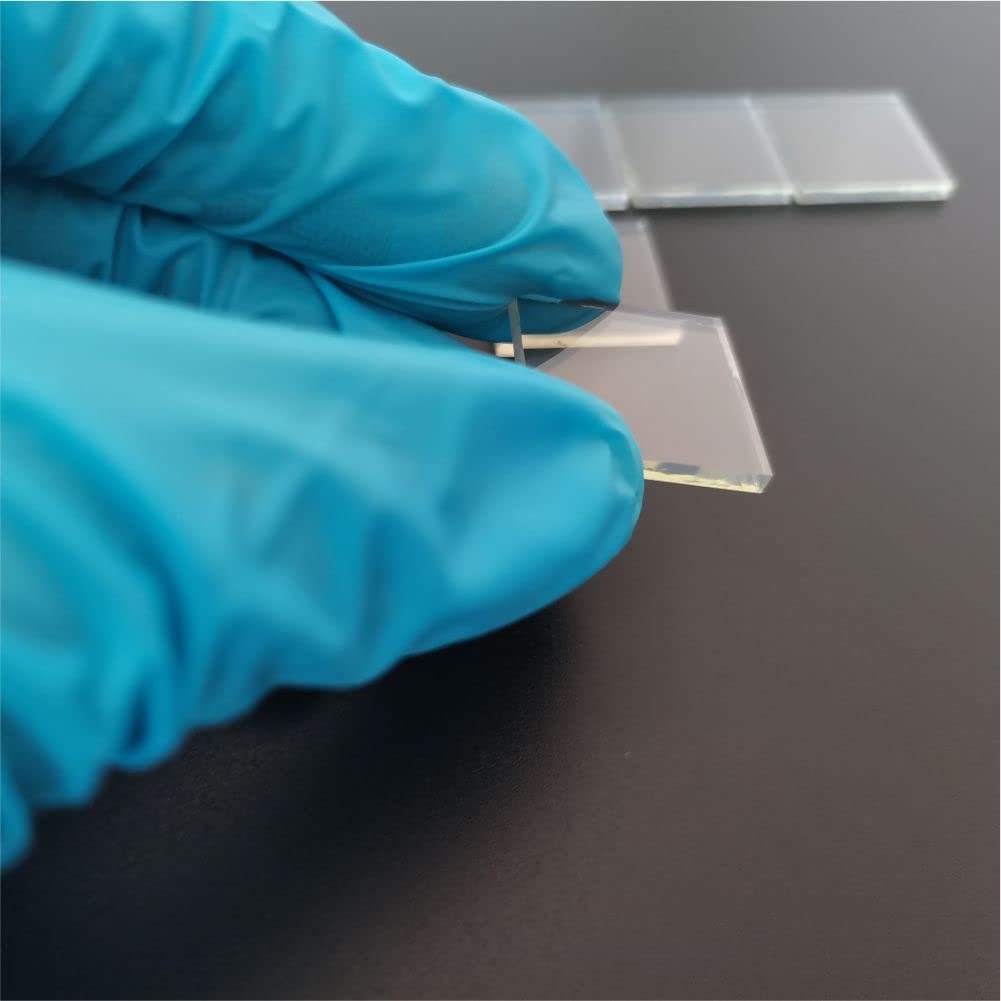

High Content Screening Microplates with Glass Bottom

Technical Specifications of HCS Glass Bottom Plates

| Parameter | Description |

|---|---|

| Plate Format | 96, 384, 1536 well formats (ANSI/SLAS compliant) |

| Bottom Material | Optical glass (Borosilicate or Fused Silica) |

| Glass Thickness | 0.17 mm ± 0.01 mm (No. 1.5) |

| Plate Body Material | Polystyrene or Cycloolefin Polymer (COP/COC) |

| Surface Treatment | Tissue Culture-treated, with optional coatings |

| Sterilization | Gamma or Ethylene Oxide |

| Compatibility | Robotic handlers and microscope stages |

What Are High Content Screening (HCS) Microplates with Glass Bottom?

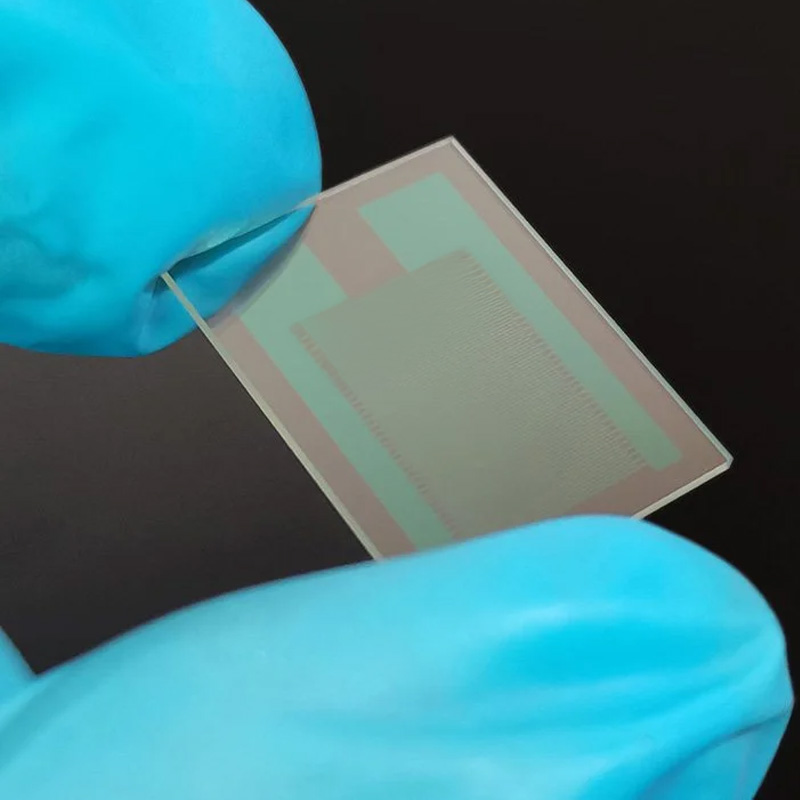

High Content Screening (HCS) Microplates with Glass Bottom are specialized imaging tools engineered for automated, high-throughput cell analysis. These microplates are designed with optical-grade borosilicate or fused silica glass bottoms, providing superior imaging quality for a wide range of biological assays. Whether you’re conducting live-cell imaging, fluorescence microscopy, or confocal studies, these plates deliver exceptional optical clarity and performance.

The key differentiator lies in the No. 1.5 cover glass thickness (0.17 mm ± 0.01 mm), the gold standard for high numerical aperture (NA) objectives used in modern microscopy. With enhanced mechanical stability, chemical resistance, and minimal autofluorescence, they are the top-tier solution for pharmaceutical, biotech, and academic research applications.

Key Benefits of Using Glass Bottom HCS Microplates

Unmatched Optical Clarity

We use precision polished borosilicate or fused silica glass, ensuring distortion-free, high-resolution imaging. This is vital when capturing quantitative data in fluorescence-based applications.

Perfect Thickness for Imaging

Each well is fitted with a 0.17 mm ± 0.01 mm cover glass, fully compatible with high-NA microscope objectives, delivering sharp, high-contrast images even at high magnification.

Low Autofluorescence for Clean Signals

Our glass material exhibits ultra-low autofluorescence, particularly in the visible and near-infrared ranges, making them ideal for confocal, TIRF, and fluorescence microscopy.

High Resistance to Solvents and Heat

Built to endure repeated sterilization, organic solvents, and thermal cycling, our plates perform reliably across harsh laboratory conditions.

Compatible Coating Options for Diverse Applications

We understand that surface chemistry plays a major role in cell attachment and viability. Therefore, we offer customizable surface treatments, including:

- Poly-D-Lysine (PDL) for neural and sensitive cells

- Collagen Type I for enhanced cell adhesion

- Gelatin and Fibronectin for tissue-mimicking environments

- Hydrophobic/Hydrophilic treatments for specific assay requirements

Each coating is applied under cleanroom conditions to ensure uniformity and sterility.

Applications of Glass Bottom Microplates in Research and Industry

High Content Screening (HCS)

Designed for high-throughput screening in automated systems, our microplates facilitate the collection of large-scale image-based data, crucial for drug discovery and genomic studies.

Live-Cell Imaging & Time-Lapse Microscopy

Maintain cellular health with optically pure surfaces and materials that do not interfere with imaging over extended periods.

Fluorescence and Confocal Microscopy

Thanks to minimal background fluorescence, these plates are the go-to choice for multi-channel fluorescence assays.

Phenotypic Screening & Toxicity Assays

The chemical inertness of our plates ensures drug compatibility while offering reproducible assay environments, making them suitable for dose-response testing.

Gene Expression & Reporter Assays

Glass-bottom wells provide unobstructed light transmission, ensuring precise fluorescence quantification of genetic reporters.

Neuroscience and 3D Cell Cultures

Custom coating options and robust well structures make these plates ideal for neuronal cultures, organoids, and spheroid formation.

Why Choose TIHOTOPTICS for Glass Bottom Microplates?

At TIHOTOPTICS, we bring precision manufacturing and biocompatible innovation together. Here’s what sets us apart:

- OEM & Private Labeling Support

- Small to Large Batch Scalability

- ISO-Certified Cleanroom Production

- CNC Glass Bonding with Micron-Level Accuracy

- Ultra-Clean Vacuum-Sealed Packaging

- Rapid Turnaround for Custom Requests

We collaborate with biotechnology startups, pharmaceutical giants, and academic labs globally to deliver tailored microplate solutions that meet evolving experimental needs.

Frequently Asked Questions (FAQs)

Q1: Are your glass bottom plates compatible with all imaging systems?

A: Yes, our microplates adhere to ANSI/SLAS standards, making them fully compatible with most robotic handlers and automated microscope stages.

Q2: Can you provide custom plate layouts or well configurations?

A: Absolutely. We offer custom plate formats, well arrangements, and even hybrid glass-polymer solutions for specialized applications.

Q3: How do you ensure sterility and optical performance?

A: Each batch undergoes gamma or ethylene oxide sterilization, along with rigorous quality checks on glass uniformity, thickness, and coating adhesion.

Q4: What is the lead time for bulk OEM orders?

A: Depending on the complexity, we typically fulfill OEM orders within 2–4 weeks, ensuring both quality and delivery commitments.

Q5: Are these plates reusable?

A: While technically reusable, we recommend single-use for critical assays to avoid cross-contamination or surface degradation.

Leave Your Message