产品: ITO Coated Glass Substrate for Optoelectronics

Featured products

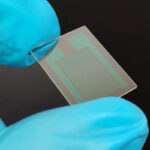

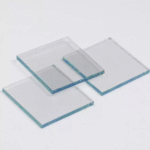

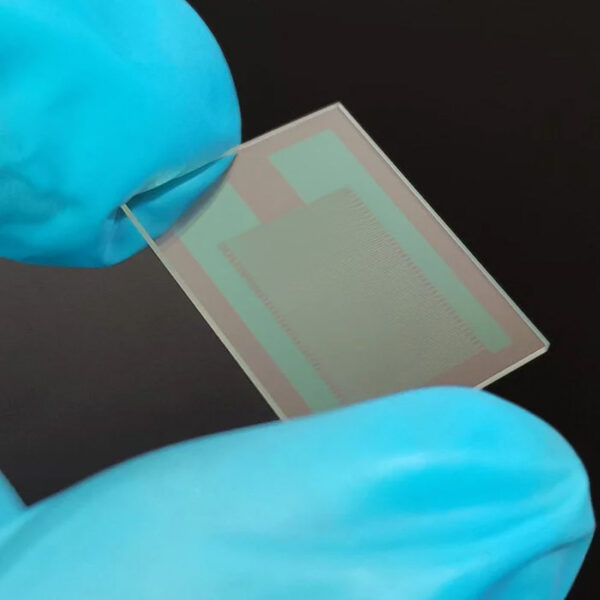

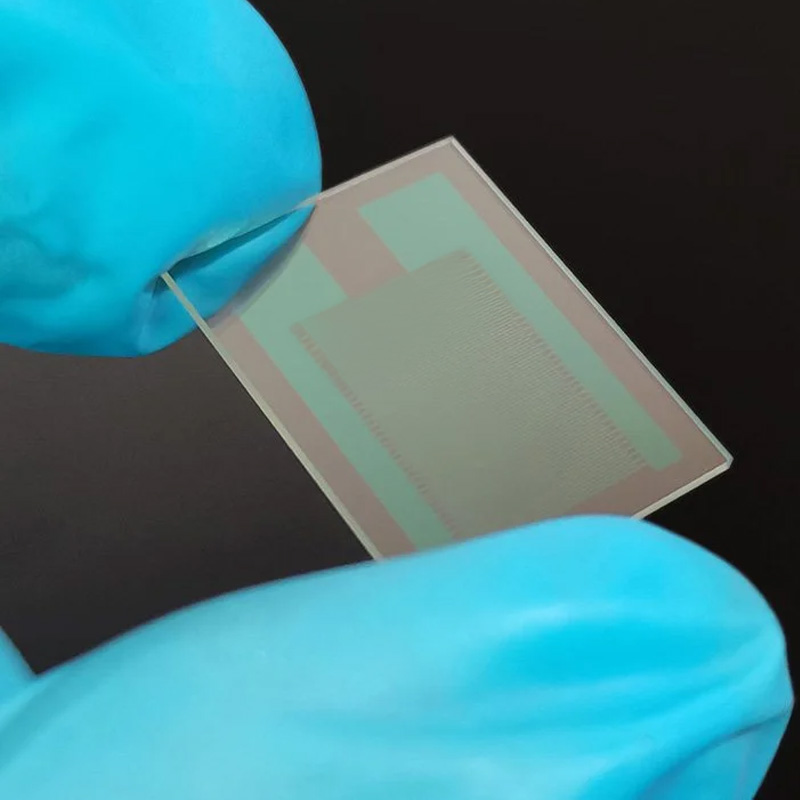

ITO Coated Glass Substrate for Optoelectronics

Technical Specifications

| Parameter | Specification Range / Options |

|---|---|

| Substrate Material | Soda lime glass |

| Conductive Layer | Fluorine Doped Tin Oxide (SnO₂:F) |

| Sheet Resistance (Ω/sq) | 6–8 Ω/sq (standard) / 10–15 Ω/sq (optional) |

| Optical Transmittance | ≥ 84% @ 550 nm |

| Temperature Resistance | Up to 500°C |

| Standard Size / Thickness | 20×20 mm / 2.2 mm (customizable) |

Product Overview

ITO (Indium Tin Oxide) Conductive Glass is a transparent conductive substrate widely used in optoelectronic and display applications. It combines excellent electrical conductivity with high optical transmittance, making it ideal for use in touch panels, sensors, OLEDs, LCD displays, and solar cells.

Our ITO glass products are manufactured using magnetron sputtering technology, ensuring a uniform coating thickness, high adhesion, and consistent sheet resistance. Each substrate undergoes ultrasonic cleaning, anti-static handling, and precision inspection to guarantee superior surface quality and optical performance.

Available Customization

-

- Custom sizes, thicknesses, and resistivity ranges

-

- Optional patterned ITO electrodes via laser etching

-

- Substrates: Borosilicate glass, quartz glass, or aluminosilicate glass available

-

- Anti-reflective, anti-fog, or hard-coating options

Features and Advantages

-

- High Optical Clarity: >84% visible light transmittance for excellent display brightness and color performance.

-

- Uniform Conductive Layer: ITO film deposited via DC/RF magnetron sputtering provides stable resistance and strong adhesion.

-

- Low Sheet Resistance: ≤6 Ω/sq ensures efficient current conduction for sensitive optoelectronic components.

-

- Superior Surface Quality: Atomically smooth glass surface with precise coating uniformity, suitable for photolithography and etching.

-

- Laser Etching Capability: Advanced laser etching equipment allows custom electrode patterns, microstructures, and fine conductive lines with high precision.

-

- RoHS Compliant: Environmentally friendly, free from hazardous substances.

Cleaning and Handling Instructions

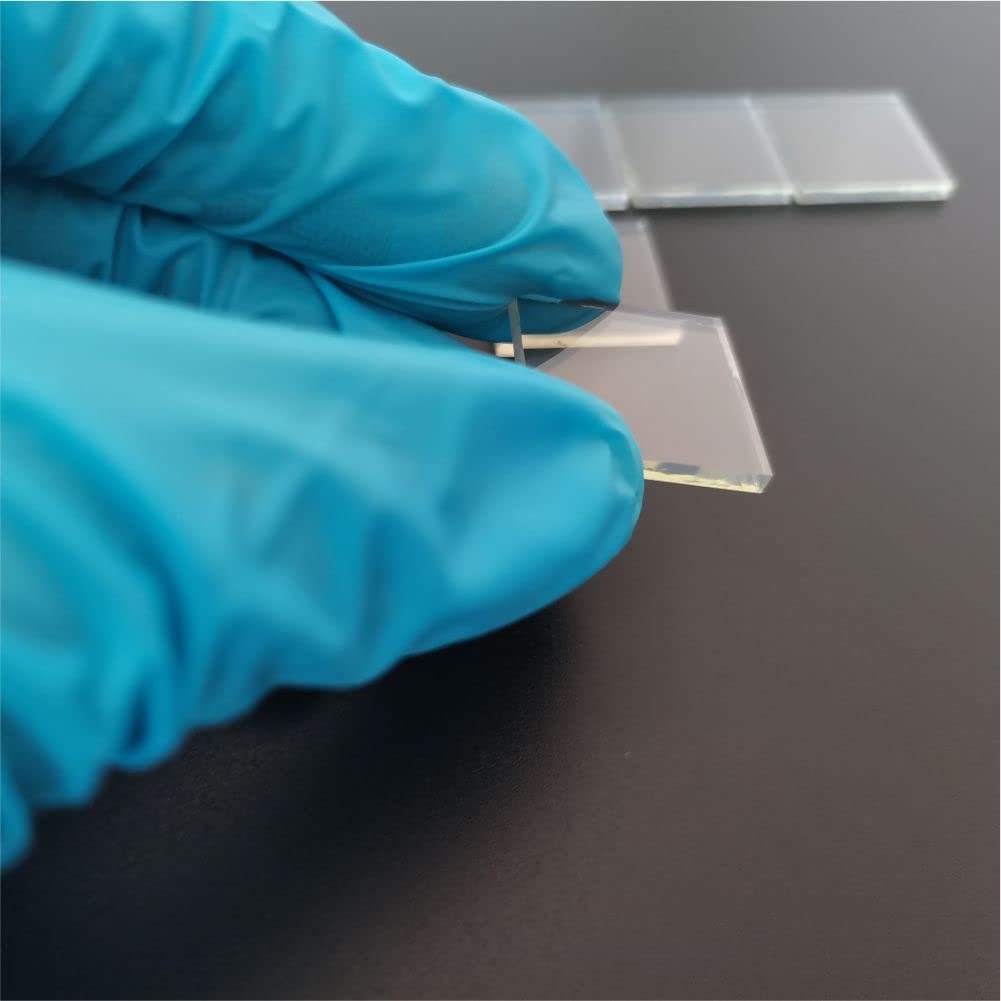

To maintain performance and prevent contamination, ITO conductive glass must be handled and stored under controlled conditions:

-

- Never stack glass sheets directly on top of each other.

-

- Vertical storage is recommended unless specified otherwise. If placed horizontally, keep the ITO-coated side facing upward.

-

- Handle only by the edges; do not touch the conductive surface.

-

- Handle with care to avoid impact or scratching from other fixtures or tools.

-

- For long-term storage, protect from moisture to prevent changes in resistance or transmittance.

-

- When designing large or elongated substrates, consider the float glass orientation to maintain uniformity.

Ultrasonic Cleaning Procedure (Recommended)

During manufacturing, packaging, or transport, the ITO surface may accumulate contaminants such as dust, oils, or residues. Proper cleaning is essential before use:

Cleaning sequence: Toluene (10–20 min) → Acetone (10–15 min) → Ethanol (10–20 min) → Deionized Water (20–30 min) → Store in anhydrous ethanol.

Each step is performed under ultrasonic vibration to ensure complete removal of organic residues without damaging the coating. This procedure ensures that the glass maintains optimal conductivity, transparency, and adhesion for subsequent processing steps.

Applications

-

- Touch Panels and Sensors

-

- OLED / LCD Displays

-

- Photovoltaic Cells and Solar Modules

-

- Electrochromic Devices

-

- Transparent Electrodes for Optoelectronics

-

- Laboratory Research and Microfabrication

Leave Your Message