Introduction— What Is Alkali-Free Glass?

Alkali-free glass represents a specialized category of engineered glass materials that contain virtually no alkali metal oxides, such as sodium oxide (Na₂O) or potassium oxide (K₂O).

This distinct composition sets it apart from conventional glass types and makes it indispensable in advanced manufacturing and high-precision applications.

The term “alkali-free” refers to the absence or extremely low concentration (typically <0.1 wt%) of alkali metal ions in the glass matrix.

Unlike ordinary soda-lime glass—which contains 12–16% sodium oxide to lower melting temperatures—alkali-free glass is formulated primarily from silicon dioxide (SiO₂) and aluminum oxide (Al₂O₃), creating a chemically stable and electrically inert substrate.

When compared to traditional soda-lime glass used in windows and bottles, alkali-free glass offers:

- Superior dimensional stability

- Minimal ion migration

- Exceptional thermal resistance

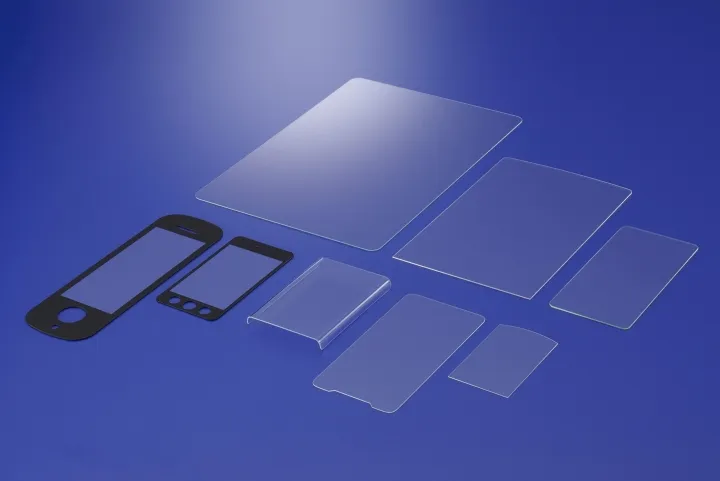

These characteristics make it the preferred substrate for TFT displays, OLED panels, and semiconductor processing, where even trace contamination can degrade performance.

The development of alkali-free glass emerged from the electronics industry’s need to eliminate ionic contamination from alkali metals—known to cause electrical instability, reduced transistor performance, and long-term reliability issues.

Today, alkali-free glass forms the foundation of nearly every flat-panel display manufactured worldwide.

Chemical Composition and Material Characteristics

The chemical composition of alkali-free glass is fundamentally based on the SiO₂–Al₂O₃ system, providing structural integrity without alkali metal oxides as network modifiers.

Typical composition:

- 50–70% SiO₂ (Silicon Dioxide)

- 10–25% Al₂O₃ (Aluminum Oxide)

- Controlled additions of B₂O₃, CaO, and MgO

Representative products:

- Corning Eagle XG® — less than 1 ppm alkali content

- NEG OA-10G — engineered for display applications

This aluminum silicate network is strengthened by alkaline earth metals like calcium and magnesium, resulting in:

- High electrical insulation (>10¹⁴ Ω·cm at room temperature)

- Excellent structural stability under high temperature and electric fields

These properties are critical for thin-film deposition processes above 600°C, ensuring no ion migration or contamination occurs during semiconductor fabrication.

Key Physical and Optical Properties

1. Thermal Expansion:

Low CTE (~3.2×10⁻⁶/K), closely matching silicon (2.6×10⁻⁶/K), prevents stress or delamination during thermal cycling.

2. Optical Transmission:

Over 90% transmittance across the visible spectrum, essential for display brightness and color accuracy.

3. Surface Quality:

Average roughness (Ra) < 0.5 nm ensures atomic-level smoothness for uniform thin-film coatings.

4. Chemical Durability:

Superior resistance to acids, alkalis, and solvents — stable even after extended exposure.

5. Mechanical Properties:

Density: 2.4–2.6 g/cm³

Young’s Modulus: ~70–75 GPa — excellent rigidity and handling strength.

These combined properties enable alkali-free glass to maintain optical clarity, dimensional precision, and durability even in extreme conditions from −40°C to +600°C.

Comparison — Alkali-Free Glass vs Borosilicate / Soda-Lime Glass

| Property | Alkali-Free Glass | Borosilicate Glass | Soda-Lime Glass |

|---|---|---|---|

| Alkali content | None (<0.1%) | Low (4–8%) | High (12–16%) |

| Thermal expansion | Very low (~3.2×10⁻⁶/K) | Moderate (~3.3×10⁻⁶/K) | High (~9×10⁻⁶/K) |

| Strain point | ~620°C | ~520°C | ~470°C |

| Electrical resistivity | >10¹⁴ Ω·cm | 10⁸–10¹⁰ Ω·cm | 10⁷–10⁹ Ω·cm |

| Ion migration | Negligible | Low | Significant |

| Surface quality | Excellent (<0.5 nm Ra) | Good | Moderate |

| Chemical durability | Excellent | Very good | Good |

| Primary application | TFT, OLED, IC | Optics, labware | Consumer glass |

| Cost | High | Moderate | Low |

Conclusion:

While borosilicate glass provides solid chemical resistance, only alkali-free glass achieves the ionic purity and dimensional stability demanded by semiconductor and display industries.

Why Choose Alkali-Free Glass for Advanced Manufacturing

1. Elimination of Ionic Contamination

Completely removes sodium and potassium ion migration — preventing voltage shifts, leakage current, and device degradation.

2. Silicon-Compatible Thermal Expansion

Minimizes thermally induced stress during processing, ensuring film integrity and higher yields in multi-step fabrication.

3. Dimensional Stability for Precision Processes

Maintains geometry under temperature and humidity fluctuations — critical for semiconductor alignment and submicron patterning.

Conclusion

The combination of technical performance, process compatibility, and environmental compliance establishes alkali-free glass as the foundation material for next-generation electronics.

As device complexity and precision demands continue to grow, alkali-free glass remains essential for maintaining the highest levels of quality, reliability, and innovation across the global technology landscape.