You might have encountered aluminosilicate glass in your smartphone screen or laboratory equipment without realizing it. This specialized glass has revolutionized industries from electronics to aerospace. However, many wonder: What exactly is aluminosilicate glass, and what makes it special?

This guide explores everything about aluminosilicate glass, from its composition to its properties. You will understand why this glass has become the choice for demanding applications and how it compares to conventional materials.

What is the Composition of Aluminosilicate Glass?

Aluminosilicate glass is manufactured by incorporating aluminum oxide (Al₂O₃) into the silicate glass matrix. The aluminum content ranges from 10% to 25% by weight, fundamentally altering the glass’s molecular structure and performance.

The manufacturing process involves melting temperatures exceeding 1600°C, significantly higher than conventional glass. The aluminum atoms integrate into the silicate network, creating stronger chemical bonds and a more robust structure.

This compositional treatment gives aluminosilicate glass these features:

- Exceptional thermal shock resistance, withstanding temperature differentials exceeding 200°C

- Superior chemical durability against acids and alkalis

- Enhanced mechanical strength 2-3 times greater than standard glass

- Low thermal expansion coefficient

- Excellent optical clarity

These characteristics make it ideal for smartphone displays, laboratory glassware, cookware, and aerospace components.

Can Standard Glass Match Aluminosilicate Performance?

The Answer is No. Standard soda-lime glass cannot match aluminosilicate’s performance in demanding applications. While ordinary glass shatters with temperature changes of 40-50°C, aluminosilicate glass handles thermal shocks exceeding 200°C without failure.

The aluminum-enriched structure provides chemical resistance that standard glass lacks. Laboratory acids that would etch regular glass have minimal effect on aluminosilicate compositions. This superior durability explains why high-end applications specify this material despite higher costs.

Aluminosilicate vs. Standard Glass: Clear Comparison

| Feature | Aluminosilicate Glass | Standard Glass |

| Thermal Shock Resistance | Excellent (>200°C differential) | Poor (40-50°C differential) |

| Chemical Durability | Superior resistance | Moderate resistance |

| Mechanical Strength | 2-3x stronger | Baseline strength |

| Cost | Higher | Lower |

| Thermal Expansion | Very low | Higher |

| Applications | High-performance | General purpose |

Why Standard Glass Fails in High-Performance Applications

Standard glass lacks the molecular structure needed for extreme conditions:

No aluminum reinforcement: Standard glass uses sodium and calcium oxides that create weaker bonds than aluminum oxide networks.

Single-phase structure: Unlike aluminosilicate’s integrated aluminum network, standard glass has a simpler structure that fails under thermal stress.

Limited temperature range: Standard glass becomes unstable at temperatures where aluminosilicate glass performs normally.

Planning to use standard glass for high-temperature or chemical-resistant applications will result in frequent failures and safety risks.

Key Applications for Aluminosilicate Glass

Aluminosilicate glass dominates several critical industries. Consumer electronics use it for smartphone screens, tablet displays, and camera lenses where scratch resistance and impact strength are essential. The material protects expensive devices from daily use damage.

Laboratory and pharmaceutical industries depend on aluminosilicate glass for reaction vessels, measurement equipment, and storage containers. The chemical inertness ensures experimental accuracy while thermal properties allow heating and cooling without equipment failure.

Industrial applications include high-temperature windows, chemical processing equipment, and specialized optical components where standard glass would fail.

Can Standard Glass be Modified to Match Aluminosilicate Performance?

Standard glass cannot be easily modified to achieve aluminosilicate performance. True aluminosilicate properties require:

Aluminum oxide integration: The aluminum must be incorporated during the melting process, not added as a surface treatment.

Specialized melting procedures: Higher temperatures and controlled cooling rates are essential for proper molecular structure formation.

Precise composition control: The ratio of aluminum to other components determines final properties and cannot be adjusted after manufacturing.

While chemical strengthening can improve standard glass, it cannot replicate the comprehensive benefits of proper aluminosilicate composition.

Which Glass Should You Select?

Choose aluminosilicate glass for applications requiring superior thermal shock resistance, chemical durability, or mechanical strength. This includes laboratory equipment, high-end electronics, cookware, and industrial components exposed to extreme conditions.

Select standard glass for general applications where cost is the primary concern and performance demands are moderate, such as basic windows, containers, and decorative items.

Can Thick Standard Glass Act Like Aluminosilicate?

Some believe thick standard glass can match aluminosilicate performance. This is false. Even at 2-inch thickness, standard glass lacks the molecular structure necessary for thermal shock resistance and chemical durability.

Thickness alone cannot provide the aluminum oxide network that gives aluminosilicate glass its unique properties. Proper high-performance glass requires specific composition, not just increased dimensions.

What Can Aluminosilicate Glass Withstand?

Aluminosilicate glass resists:

- Extreme temperature cycling from cryogenic to 500°C+

- Concentrated acids and caustic solutions

- High mechanical loads and impact forces

- Thermal expansion stresses

- Environmental weathering and UV exposure

These capabilities explain why it’s specified for critical applications where failure is not acceptable.

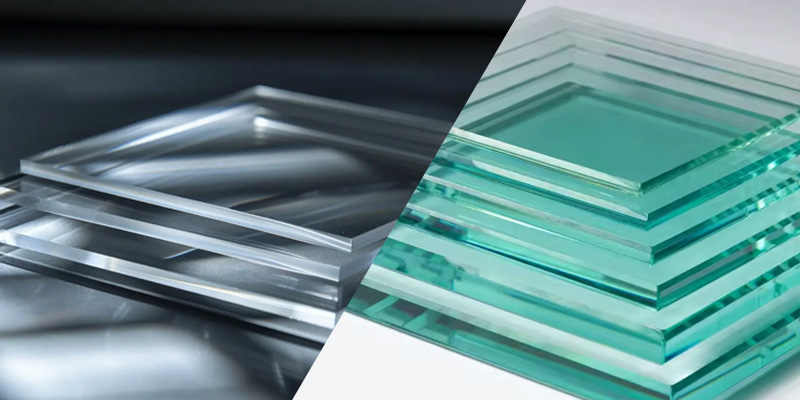

Visual Differences Between Aluminosilicate and Standard Glass

Aluminosilicate Glass: Often appears slightly thicker due to performance requirements. May have subtle differences in optical clarity and can show manufacturer markings indicating composition. Edges appear more precisely finished due to specialized processing.

Standard Glass: Typically thinner for equivalent applications. May show slight green tint from iron content. Generally has simpler edge finishing and lower manufacturing precision.

Weight differences are minimal, but aluminosilicate glass often requires heavier mounting hardware due to its applications rather than material density.

Conclusion

Aluminosilicate glass offers superior thermal shock resistance, chemical durability, and mechanical strength compared to standard materials. Understanding these properties enables proper material selection for specific applications. Whether designing laboratory equipment, electronics, or industrial systems, knowing when to specify aluminosilicate glass can dramatically improve performance and reliability.

If you’re uncertain about which glass type suits your project or need guidance on performance specifications, consulting with materials specialists is essential. The right choice enhances safety, reduces maintenance costs, and ensures long-term performance.