ITO means indium tin oxide. This coating makes glass both transparent and electrically conductive. ITO coating glass is used in touch screens, displays, solar cells, and sensors. Makers and buyers use ITO glass to get materials that combine light transmission with electrical conductivity. Knowing about ITO helps people choose the right transparent conductive glass for their applications.

ITO coating glass keeps light passing through while allowing electrical current to flow. This makes it work in devices that need both light and electricity. High-quality ITO glass has optical transmission from 80 to 90 percent and sheet resistance from 10 to 100 ohms per square. These numbers matter because they show how well the coating balances clarity and conductivity.

ITO Coating Glass Overview

ITO is a transparent conductive oxide (TCO). This material is an extremely thin metal-oxide layer applied to glass surfaces. The coating lets light pass through while conducting electricity. Normal glass blocks electrical current and cannot conduct electricity. ITO-coated glass does both—it stays clear and conducts electricity at the same time.

The reason to coat glass with ITO is simple: you get a material that works like two things at once. It acts as a transparent window and as an electrical conductor. This dual property makes ITO glass essential in modern electronics.

ITO coating is measured in nanometers, usually between 100 and 200 nanometers thick.

The thickness affects both optical and electrical performance:

- Thicker coatings conduct electricity better but let less light through.

- Thinner coatings transmit more light but conduct electricity less well.

The balance between these two properties determines the quality and cost of the final product.

How Is ITO Coating Glass Made?

ITO coating starts with a clean glass substrate, such as:

- Soda-lime glass

- Borosilicate glass

- Quartz glass

The substrate is cleaned thoroughly to remove dust and impurities. Cleanliness is critical because any particles can affect coating quality.

The Magnetron Sputtering Process

The coating process happens in a vacuum chamber, using magnetron sputtering — the most common deposition method.

This process works by striking a target made of indium tin oxide with high-energy particles. These particles knock atoms from the target, and those atoms travel through the vacuum and land on the glass surface. The atoms bond to form a thin, uniform ITO layer.

Main steps in ITO coating:

Inside the vacuum chamber, the cleaned glass substrate is securely positioned on the target holder.

Once the chamber is fully evacuated to eliminate residual air and moisture, the sputtering process begins—ionized gas particles strike the ITO target, ejecting indium–tin–oxide atoms that deposit evenly onto the glass surface.

Film thickness is precisely managed through deposition time and real-time sensor feedback to ensure uniform coating.

After deposition, the substrate undergoes thermal annealing, a heating process that enhances coating adhesion, transparency, and electrical conductivity.

Finally, each coated glass sheet is inspected for thickness accuracy, optical transmission, and surface resistance to guarantee consistent quality.

Different sputtering methods exist:

- DC magnetron sputtering works well for conductive coatings.

- RF (radio frequency) magnetron sputtering works better for non-conductive materials.

- Some makers use hybrid methods combining both.

The choice depends on the desired coating quality and production speed.

Annealing and Quality Control

The annealing step is crucial. Heating the coated glass to 150–300 °C improves the crystalline structure of the ITO layer. This increases conductivity and adhesion to the substrate.

Temperature control is important because too much heat can damage the glass or cause uneven coating.

Key Properties of ITO Glass

ITO glass has several important properties that determine its usefulness. Understanding these helps you select the right material for your application.

- Transparency and Conductivity

Transmits 80–90% of visible light while remaining electrically conductive.

Sheet resistance ranges from 10–100 Ω/□ (ohms per square).

Lower values mean better conductivity but often lower transparency. - Surface Roughness

Affects how the coating interacts with other layers.

Measured by AFM (Atomic Force Microscopy) in RMS values.

Smoother surfaces provide better adhesion and optical clarity. - Adhesion Strength

Indicates how well the ITO layer bonds to the glass substrate.

Poor adhesion causes peeling or cracking during use or temperature changes. - Thermal Stability

ITO glass can handle temperatures up to 400 °C in many applications. - Chemical Stability

Shows resistance to acids, bases, and solvents — important for harsh environments.

Common Substrate Materials for ITO Coating

Different glass types work as substrates for ITO coating. Each has unique benefits for specific applications.

1. Soda-Lime Glass

- Most common and cost-effective option.

- Suitable for displays, touch screens, and LCD panels.

- Easier to process due to its lower melting point.

- Lower thermal stability compared to borosilicate and quartz glass.

2. Borosilicate Glass

- Offers higher thermal and chemical stability.

- Resists sudden temperature changes.

- Used in higher-temperature or chemically demanding applications.

- Moderately priced between soda-lime and quartz glass.

3. Quartz Glass

- Provides the highest optical quality and thermal stability.

- Transmits UV light, ideal for optical and semiconductor applications.

- The most expensive substrate, chosen for maximum clarity and extreme conditions.

Summary:

Choose soda-lime glass for general displays, borosilicate for higher durability, and quartz for precision optics and UV applications.

Applications of ITO Coating Glass

ITO glass is used in many modern technologies. Its combination of transparency and conductivity makes it indispensable in electronics and optics.

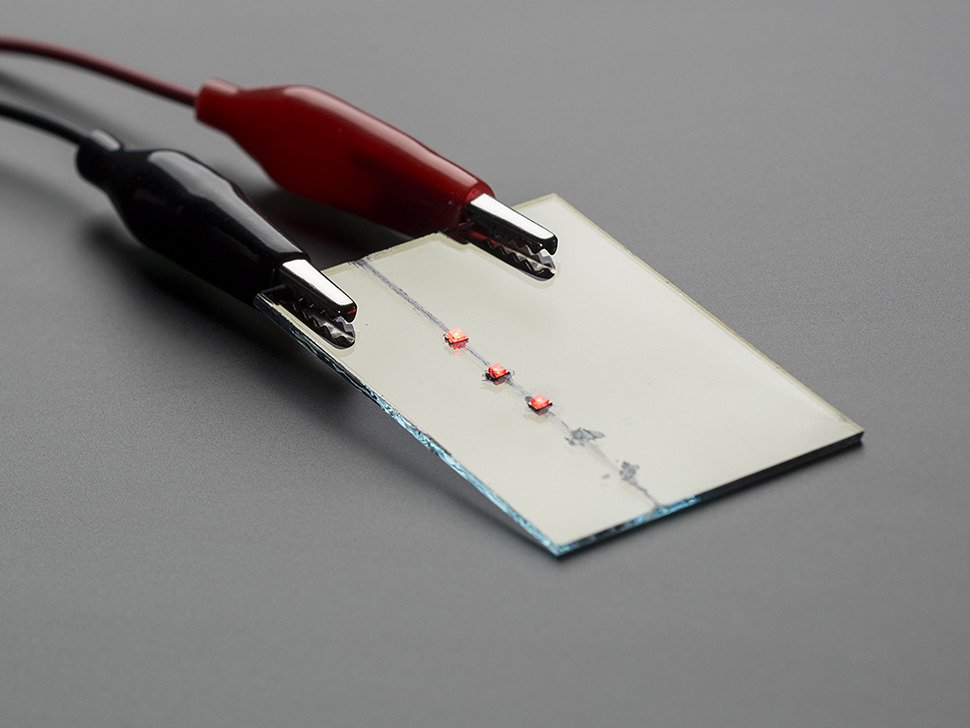

- Touch Screens & Displays

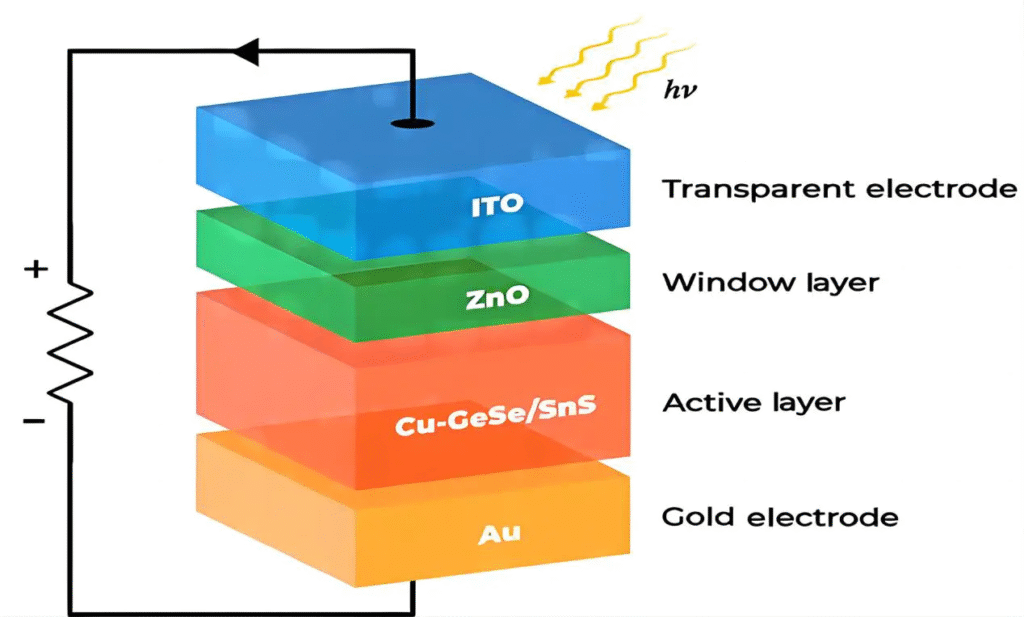

Used as transparent electrodes in smartphones, tablets, LCDs, OLEDs, and LED panels. - Solar Cells

Functions as a transparent front electrode, allowing light to pass to photovoltaic materials while collecting electrical current. - Optical Sensors & Photodetectors

Enables light detection with electrical connection — used in biosensors, environmental sensors, and lab instruments. - Research & Laboratory Applications

Common in microfluidics, biosensors, thin-film electronics, and electrochemistry experiments.

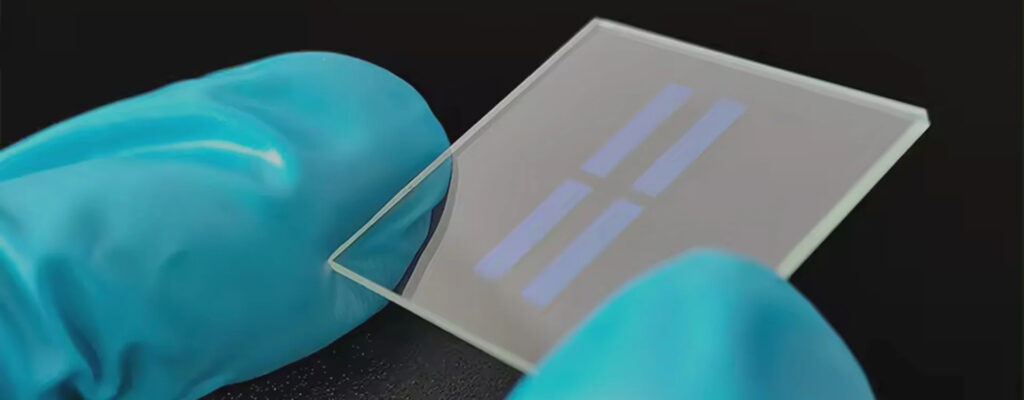

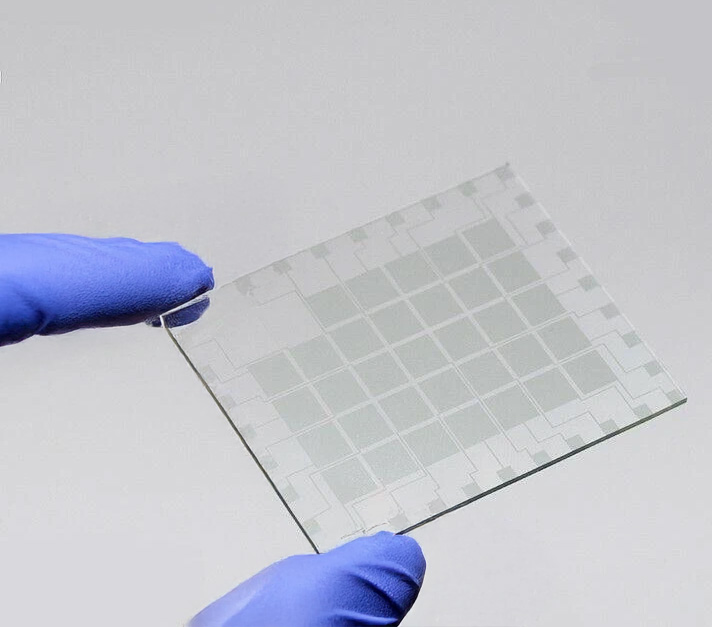

Custom ITO Coating and Patterning Services

TIHOTOPTICS offer custom ITO coating to meet specific needs.

You can order ITO glass in various sizes, shapes, and resistance levels — such as round wafers, rectangular sheets, or custom geometries.

Customization Options

- Sheet resistance: 10–100 Ω/□

- Coating thickness & transparency: Tuned for each application

- Patterning: via laser etching or photolithography

Laser Etching — removes ITO in specific patterns with focused beams.

Photolithography — uses photoresist and UV exposure to define electrode areas.

Patterned ITO glass is used in specialized devices requiring precise electrode geometry.

Custom services provide application-optimized solutions instead of one-size-fits-all products.

ITO Glass vs FTO Glass

FTO stands for fluorine-doped tin oxide.

Both ITO and FTO are transparent conductive oxides (TCOs), but they differ in performance and use cases.

| Property | ITO Glass | FTO Glass |

|---|---|---|

| Optical clarity | Higher | Lower |

| Sheet resistance | Lower (better conductivity) | Higher |

| Adhesion & stability | Moderate | Stronger |

| Chemical resistance | Moderate | Higher |

| Cost | Higher | Lower |

| Typical use | Displays, precision optics | Solar cells, electrochemistry |

ITO is ideal for high-performance displays and optics.

FTO is better for industrial, cost-sensitive, or harsh-environment applications.

Conclusion

ITO coating glass is a dual-function material combining light transmission with electrical conductivity.

It is essential in modern displays, solar technology, sensors, and research applications.

The ability to customize thickness, sheet resistance, and patterning makes ITO glass adaptable to many specialized needs.

If you need custom ITO coating for your application, contact a manufacturer to discuss your specific requirements.

The right ITO glass solution improves device performance and reliability.