产品: Corning Eagle XG® Glass Wafers

Featured products

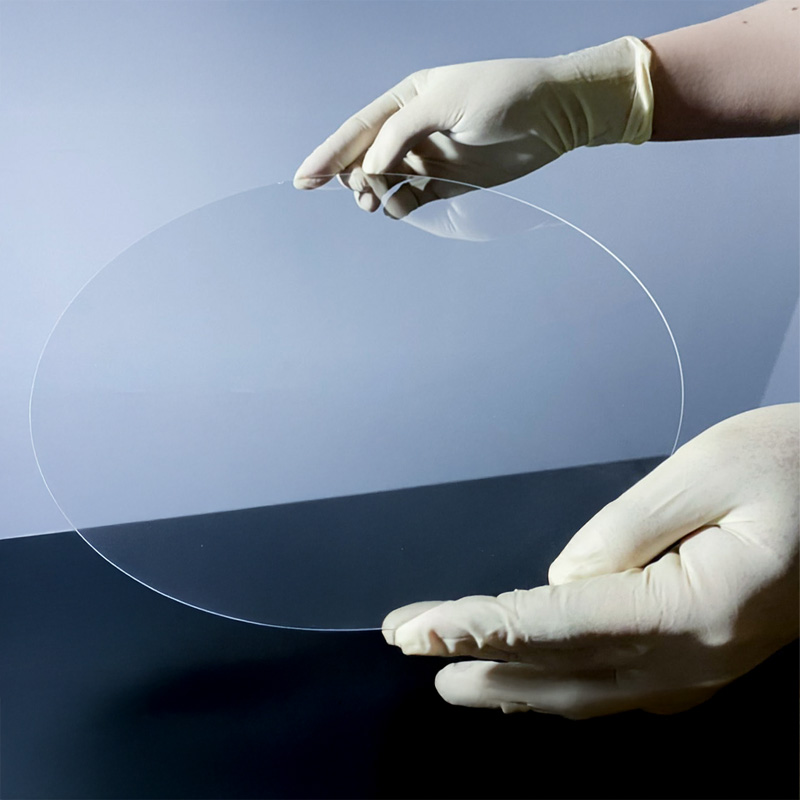

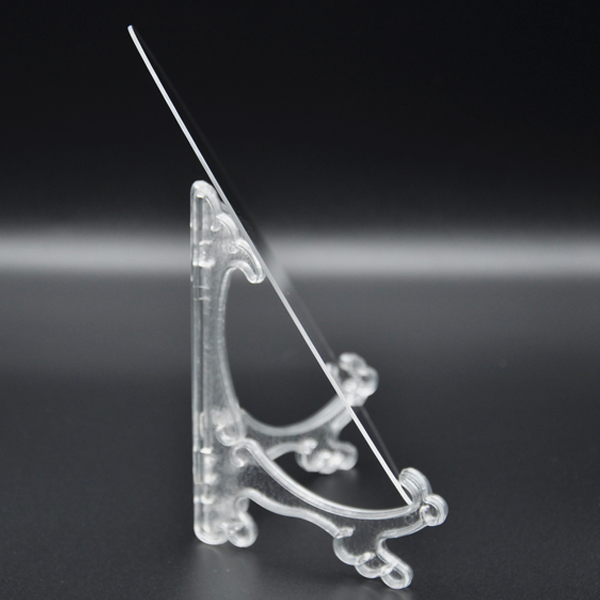

Corning Eagle XG® Glass Wafers

Key Technical Specifications – Corning Eagle XG®

| Property | Value | Unit / Notes |

|---|---|---|

| Type | Alkali-free display glass | Free of Na⁺, K⁺, As, and heavy metals |

| Density | ~2.38 | g/cm³ |

| Thermal Expansion Coefficient | ~3.2 × 10⁻⁶ | /K (20°C–300°C), silicon-compatible |

| Young’s Modulus | ~73 | GPa |

| Refractive Index | ~1.51 | @ λ = 587.6 nm |

| Surface Roughness | < 0.5 | nm (as-drawn), can be polished to Ra ≤ 0.01 µm |

| Transmission | >90% | 400–700 nm visible range |

| Softening Point | ~820 | °C |

| Annealing Point | ~639 | °C |

| Lead/Arsenic Content | None | RoHS & REACH compliant |

Overview: What is Corning Eagle XG® Glass?

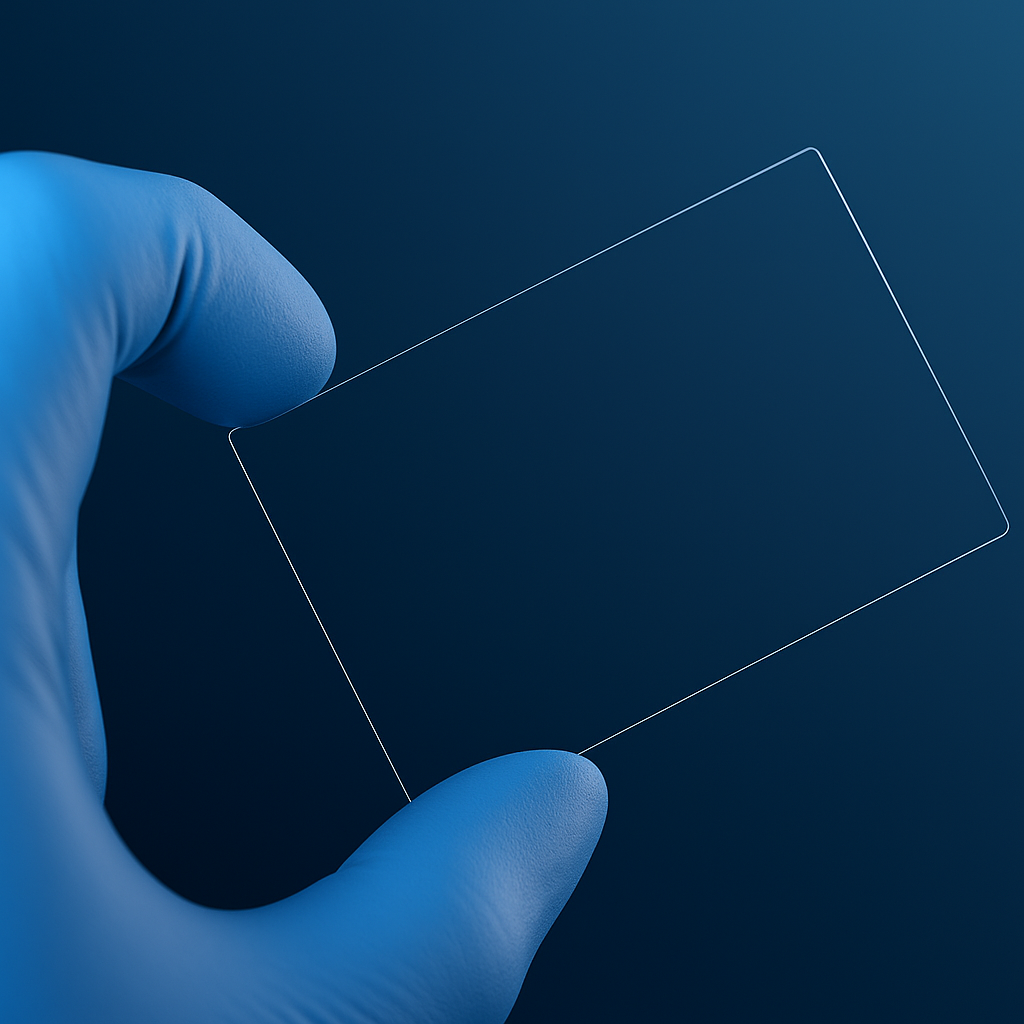

Corning Eagle XG® is a high-performance, alkali-free display glass designed specifically for advanced TFT-LCD, OLED, and semiconductor applications. Manufactured using Corning’s fusion draw process, it offers ultra-flat surfaces, high dimensional stability, and exceptional optical clarity.

Unlike traditional glass substrates, Eagle XG® is free of heavy metals such as arsenic and antimony and supports environmentally sustainable manufacturing. With its low thermal expansion and high surface quality, it is widely used in photolithography, display panel fabrication, and thin-film deposition.

Why Choose Eagle XG® Glass Wafers for High-Precision Applications?

- Alkali-Free Composition: No sodium or potassium ions—ideal for IC, TFT, and OLED integration.

- Thermal Compatibility: CTE matched with silicon and other semiconductor materials (~3.2 × 10⁻⁶ /K).

- High Optical Clarity: Over 90% transmission in the visible spectrum; excellent for imaging and photomask use.

- Ultra-Smooth Surface: Surface roughness < 0.5 nm; ideal for thin-film and microfabrication.

- Eco-Friendly Material: Free from lead, arsenic, and antimony; fully RoHS & REACH compliant.

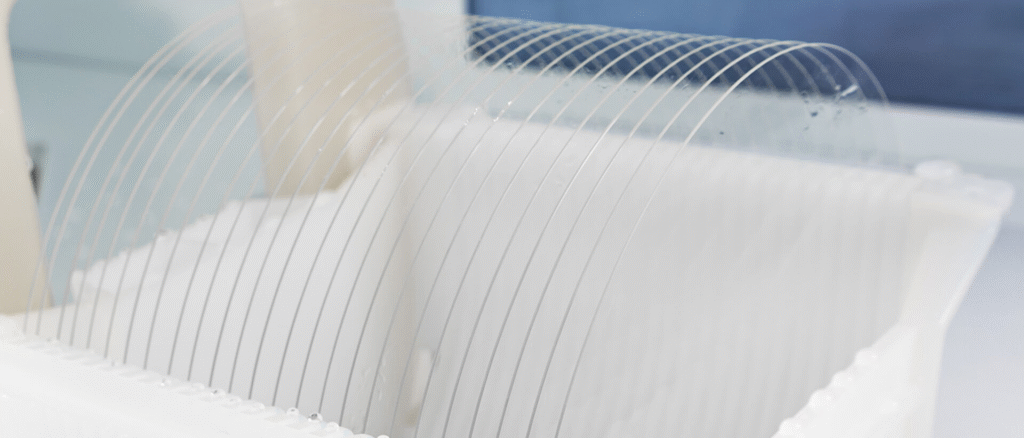

Your Trusted Eagle XG® Wafer Supplier and Custom Processor – TiHot

TiHot is a direct manufacturer and custom processor of Corning Eagle XG® glass wafers. We specialize in OEM and small-batch fabrication, serving display, electronics, and research industries worldwide.

Our in-house engineering and cleanroom teams offer:

Global export logistics with RoHS documentation and MSDS support

Small- and large-batch Eagle XG wafer supply

Drawing-based precision customization (DXF / STEP / PDF compatible)

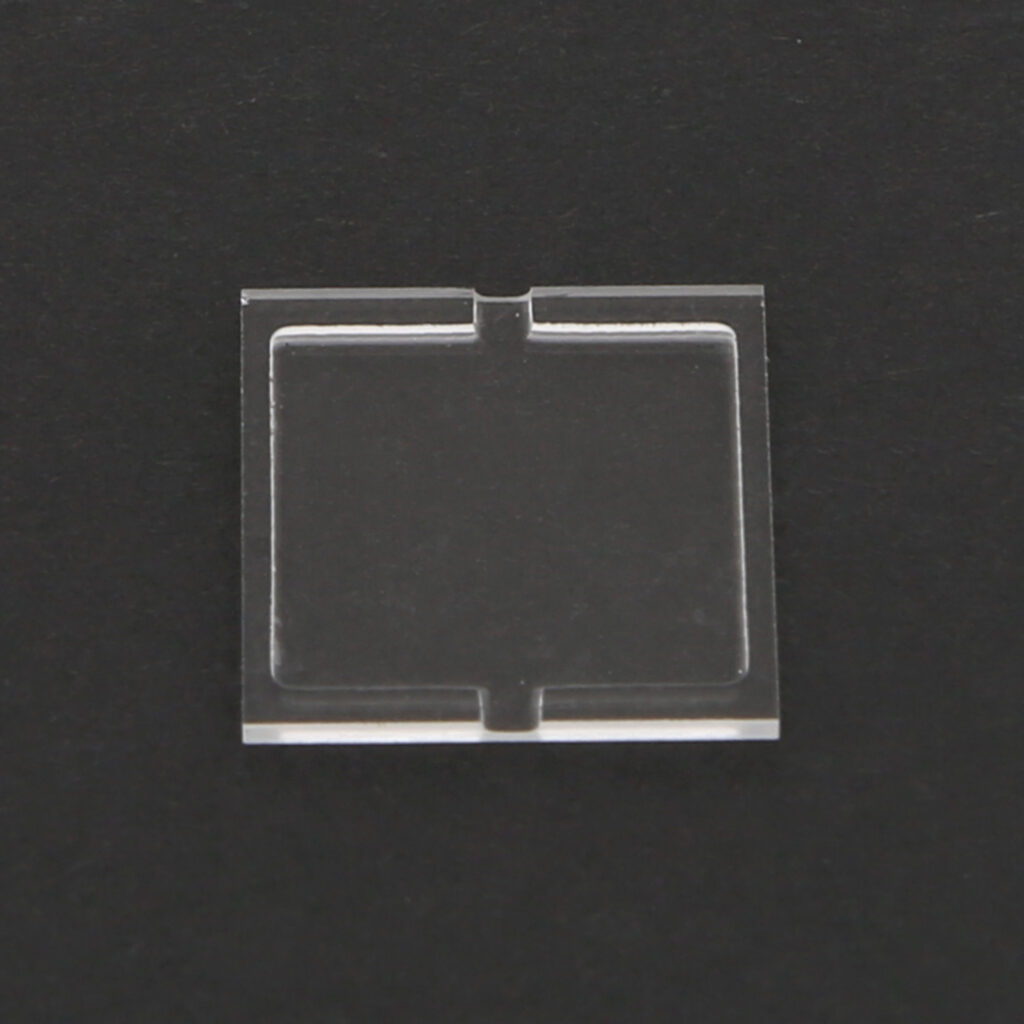

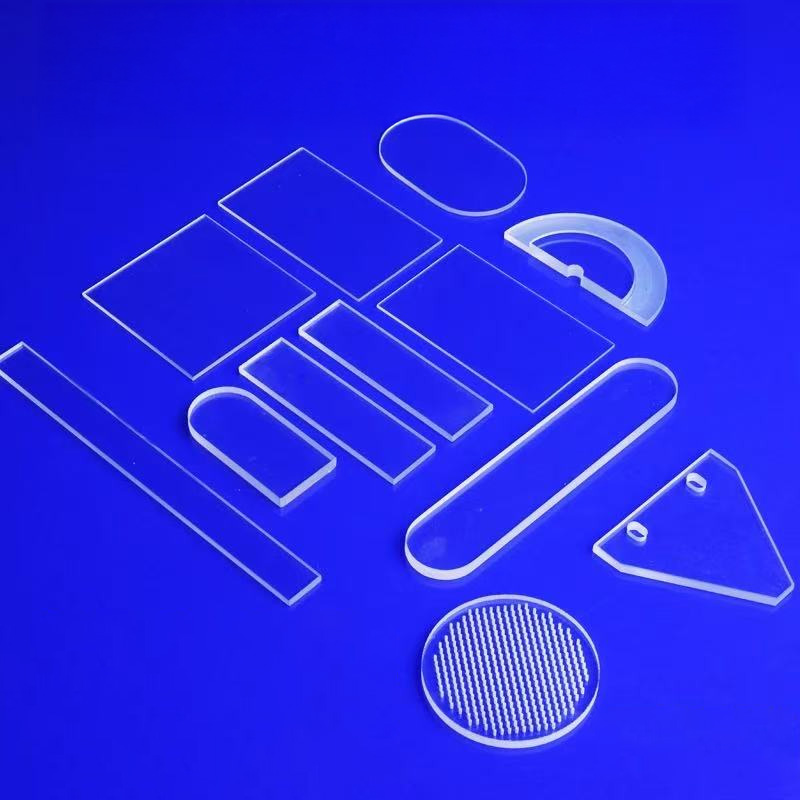

Eagle XG® Glass Wafer Processing Capabilities

We provide a full suite of CNC and polishing services for ultra-thin and full-thickness Eagle XG glass:

- Precision Cutting: Up to ±0.01 mm tolerance, any shape or profile

- CNC Slotting & Dicing: For photomask, panel, or MEMS applications

- Edge Finishing: C-edge, D-edge, beveled, or chamfered for safe handling

- Micro Drilling & Channeling: Hole diameters ≥ 0.1 mm supported

- Surface Polishing: Optical polish, lapping (Ra ≤ 0.01 µm) for thin-film use

- Coating Services: ITO, FTO, dielectric, and AR coatings available

- Thermal Processing: Annealing and thermal strengthening upon request

All wafers undergo ISO-compliant quality inspection and CAD/CAM-ready processing.

Industries and Applications Served

Display and Flat Panel Technology

- TFT-LCD panel glass

- OLED backplane substrates

- Color filter and touch panel carriers

Semiconductor and Photonics

- Photolithography masks

- Thin-film deposition carriers

- Wafer-level display packaging

Biomedical and Diagnostics

- Transparent microfluidic chips

- Bio-imaging substrates

- Optical-grade microscope covers

Laser and Precision Optics

- Calibration targets and alignment plates

- IR-transparent inspection windows

- Laser shielding panels

Supporting Research Institutions and Innovation Labs

TiHot is a trusted supplier of custom Eagle XG wafers to global research centers, display fabs, and microfabrication labs. Whether you require:

- Ultra-thin substrates for flexible electronics

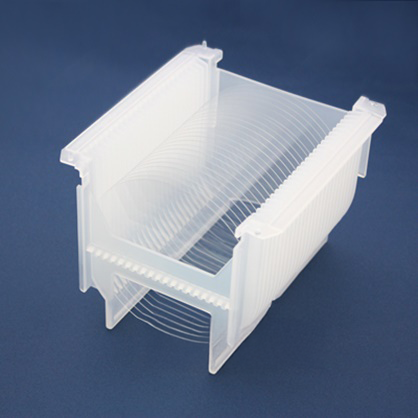

- Cleanroom-packaged photomask carriers

- ITO-coated transparent wafers for prototyping

Our team supports rapid prototyping, tight-tolerance production, and long-term R&D cooperation with:

- Sample-based development support

- Cleanroom-ready packaging with full documentation

- Flexible MOQ and lead time optimization

People Also Ask

1.Can Corning Eagle XG wafers be customized into round or square formats?

Yes. We provide full-shape customization—round (2″, 4″, 6″) or square (up to 300 mm), with ultra-thin or standard thickness.

2.What thicknesses are available for Eagle XG wafers?

We support thicknesses from 0.2 mm to 1.1 mm. Custom thicknesses can be polished down on request.

3.Is Eagle XG glass suitable for photolithography or OLED processes?

Absolutely. Its ultra-low ion content and thermal stability make it ideal for advanced microfabrication.

4.Can Eagle XG wafers be coated with ITO or AR layers?

Yes. We offer ITO, FTO, dielectric, and anti-reflective coatings with tight uniformity control.

5.Do you support small-batch or R&D orders for Eagle XG wafers?

Yes. TiHot welcomes prototype and low-volume orders for labs, universities, and pilot projects.

6.Is edge polishing or safety chamfering available?

Yes. All wafers can be edge-finished for improved durability, alignment, and safe handling.

7.What is the minimum feature size you can machine on Eagle XG wafers?

Using CNC micro-machining and laser drilling, we can achieve feature sizes as small as 100 µm, suitable for microfluidic channels, sensor slots, or via holes.

8.Do you support double-side polishing or lapping for Eagle XG wafers?

Yes. We offer double-side optical polishing and lapping with surface roughness as low as Ra ≤ 0.01 µm, ensuring excellent flatness and bonding compatibility.

9.Can Eagle XG wafers be laser cut or diced without edge chipping?

Absolutely. We use precision laser dicing and CNC scribing to minimize edge microcracks, especially for ultra-thin wafers. Chamfering or beveled edge processing is also available for enhanced durability.

Customizable Eagle XG® Wafer Dimensions

| Parameter | Customizable Range | Notes |

|---|---|---|

| Shape | Round / Square / Irregular | Based on drawing (DXF / STEP) |

| Diameter (Round) | 10 mm – 300 mm | 2″, 4″, 6″, 8″ common sizes |

| Side Length (Square) | Up to 300 mm | Rectangular or square |

| Thickness | 0.2 mm – 1.1 mm | Ultra-thin or standard available |

| Thickness Tolerance | ±0.01 mm – ±0.05 mm | Optical grade available |

| Edge Options | Ground / Chamfered / C-edge / D-edge | For safe handling & alignment |

| Surface Finishing | As-cut / Ground / Polished / Optical | Ra ≤ 0.01 µm optional |

| Drilling/Hole Size | ≥ 0.1 mm diameter | Microhole arrays supported |

| Coating Services | ITO / FTO / AR / Dielectric | Applied upon request |

| Packaging | Cleanroom-grade with barcode/label | Double-side protection film optional |

All Corning Eagle XG® wafers are made-to-order. TiHot supports fast prototyping, small-batch production, and full OEM service.

Leave Your Message